Gypsum grinding production line is a complete equipment system specifically designed to process natural gypsum ore or industrial by-product gypsum into gypsum powder of varying fineness. As a crucial raw material processing equipment for industries such as construction, medical care, and food, modern gypsum grinding production lines integrate crushing, grinding, grading, calcining, and conveying, achieving automated and intelligent gypsum powder processing.

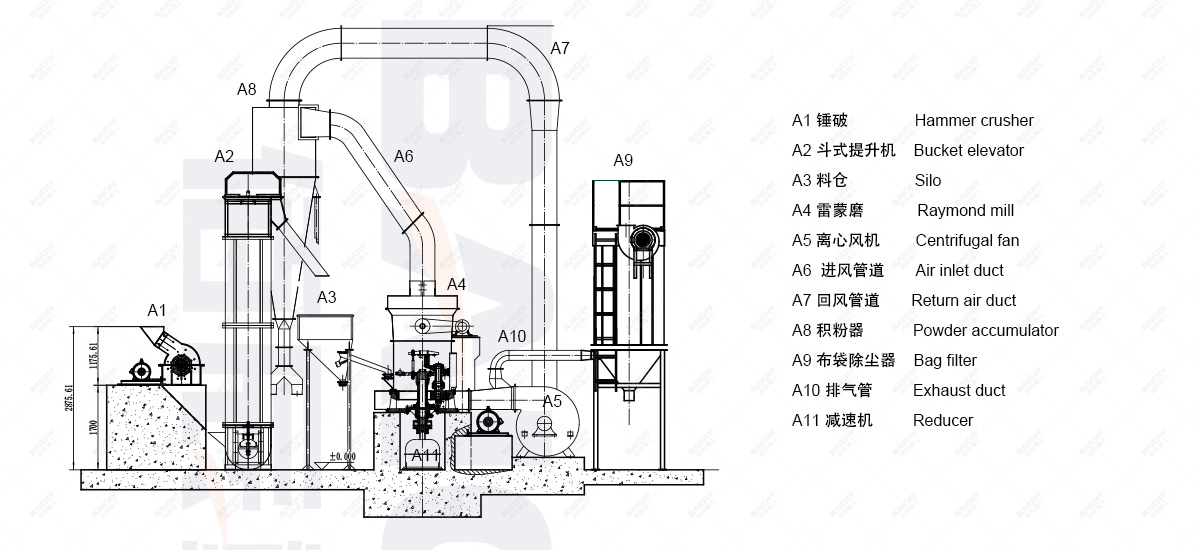

A jaw crusher or hammer crusher is used for primary crushing of the raw material, reducing bulky gypsum ore to particles ≤30mm.

Technical Features:

• Feed Particle Size: ≤400mm

• Discharge Particle Size: ≤30mm

• Processing Capacity: 10-100t/h

Core equipment includes Raymond mills, vertical mills, and ball mills, with different types selected based on the required fineness of the finished product.

| Equipment Type | Applicable Fineness Range | Production Capacity Range | Energy Consumption Comparison |

| Raymond Mill | 80-400 Mesh | 3-25t/h | Medium |

| Vertical Mill | 200-800 Mesh | 5-50t/h | Lower |

| Ball Mill | 325-2500 Mesh | 2-15t/h | High |

A high-efficiency turbine classifier is used to achieve precise particle size control and ensure uniformity in the finished gypsum powder.

• Ordinary gypsum powder: ±5μm

• High-precision gypsum powder: ±2μm

• Raw Material Pretreatment: Gypsum ore → Crushing → Screening → Storage

• Grinding Process: Raw material → Dosing → Grinding → Classification

• Finished Product Processing: Collection → Packaging → Warehousing

• Calcination Temperature: 150-180°C

• Calcination Time: 1.5-2 hours

• Dehydration Rate: ≥75%

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery