DG single-cylinder cone crusher occupies an important position in the field of ore crushing with its advantages of efficient crushing capacity, stability and reliability, intelligent control, energy saving and environmental protection, easy maintenance, and wide application.

Single Cylinder Hydraulic Cone Crusher is a high-efficiency crushing equipment that uses a hydraulic adjustment system to control the size of the discharge port and achieve overload protection. Its core feature is the single cylinder hydraulic structure. The main shaft and the moving cone are supported by the hydraulic cylinder to achieve precise crushing gap adjustment and automatic cavity clearing function. It is suitable for medium and fine crushing of medium and high hardness ores and rocks, and has the advantages of high output, low energy consumption, and intelligent control.

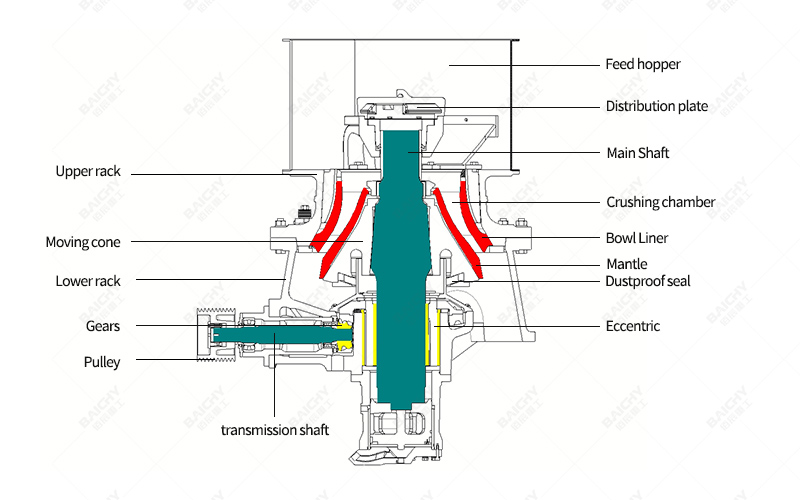

Main frame: High-strength cast steel or welded structure is adopted to ensure the stability of the equipment under heavy load.

Crushing chamber type: A variety of chamber designs (such as standard type and short head type) are available. By replacing the liner to adapt to the needs of different particle sizes, the chamber type optimization can increase the output and reduce the needle-like content.

• Hydraulic cylinder: Integrated at the bottom of the main shaft, the main shaft and the moving cone are supported by hydraulic pressure to achieve discharge port adjustment (usually in the range of 3-60mm) and iron protection.

• Accumulator: Buffer sudden impact force, reduce equipment vibration, and protect core components.

• The main shaft is made of high-strength alloy steel and is rigidly connected to the moving cone to form a "cantilever" structure, and dynamic eccentric rotation generates crushing force.

Intelligent control system

• Optional PLC control, real-time monitoring of parameters such as main shaft position, hydraulic pressure, motor current, etc., to achieve automatic adjustment and fault diagnosis.

Single-cylinder cone crusher for mining

Single-cylinder cone crusher price

Single-cylinder cone crusher

Single-cylinder hydraulic cone crusher

1. High efficiency: The lamination crushing principle makes the material particle shape better, the qualified rate is increased by 20%-30%, and the energy consumption is 15%-20% lower than that of the spring cone crusher.

2. Convenient maintenance: The hydraulic system replaces the traditional spring structure, simplifies the adjustment and cavity cleaning operations, and reduces the maintenance time by more than 50%.

3. Long-life design: Key components such as the main shaft adopt forging technology, and the liner uses high manganese steel or composite alloy, with a life of up to 8000-12000 hours.

4. Environmental protection and low noise: closed dust-proof design, with dust removal device, the noise is less than 75dB, meeting environmental protection requirements.

• Mining: Crushing iron ore, copper ore, granite, etc., feed size ≤560mm, processing capacity 50-1500t/h.

• Aggregate production: used for machine-made sand and high-quality gravel processing, the finished product size can be adjusted to 3-30mm.

• Metallurgical slag processing: finely crush steel slag and furnace slag to recover metal resources.

Differences between cone crusher and jaw crusher in the crushing principle and application scenario: jaw crusher adopts extrusion crushing, and coarsely crushes large pieces of materials (large feed size, up to 1500mm) through the reciprocating motion of the movable jaw and the fixed jaw, which is suitable for primary crushing and has a simple structure and convenient maintenance, but the finished product particle shape is poor; cone crusher uses lamination crushing (moving cone swings to squeeze materials), and is good at medium and fine crushing of medium and high hardness ores (such as granite, iron ore), and the finished product particle size is uniform (3-60mm) and the particle shape is excellent, but the equipment is complex and the cost is high. In short, the jaw crusher is the "first choice for coarse crushing" and the cone crusher is the "expert in fine crushing".

The single-cylinder hydraulic cone crusher adopts the principle of laminated crushing. The motor drives the eccentric sleeve to rotate, driving the moving cone to do a pendulum motion, so that the material is squeezed, impacted and sheared in the crushing chamber to achieve continuous crushing.

• Hydraulic adjustment of the discharge port: By adjusting the pressure of the hydraulic cylinder, the position of the moving cone is accurately controlled, the crushing gap is changed, and the discharge of different particle sizes is achieved.

• Hydraulic over-iron protection: When unbreakable objects (such as iron blocks) enter the cavity, the hydraulic system automatically releases pressure, and the moving cone quickly descends to discharge foreign objects to avoid equipment damage.

• Hydraulic cavity clearing function: When the machine is shut down, the hydraulic system can be operated with one button to lift the moving cone, quickly clear the blocked materials, and reduce manual maintenance time.

| Model | Cavity Type |

Max Feeding Size(mm) |

Adjusting Range of Discharge Opening (mm) |

Capacity (t/h) |

Power (kw) |

| Standard Cavity Type | |||||

|

CH420 (DG100) |

Extra Coarse - EC | 155 | 10-32 | 46-128 | 90 |

| Coarse - C | 103 | 10-32 | 13-118 | ||

| Medium - M | 76 | 8-19 | 36-80 | ||

| Medium Fine - MF | 58 | 6-16 | 36-71 | ||

| Fine - F | 42 | 4-16 | 27-57 | ||

|

CH430 (DG200) |

Extra Coarse - EC | 185 | 13-38 | 69-208 | 160 |

| Coarse - C | 150 | 13-38 | 66-197 | ||

| Medium - M | 101 | 10-32 | 64-162 | ||

| Medium Fine - MF | 86 | 8-25 | 61-126 | ||

| Fine - F | 62 | 6-25 | 48-103 | ||

|

CH440 (DG300) |

Extra Coarse - EC | 220 | 16-44 | 114-395 | 220 |

| Coarse - C | 175 | 13-44 | 101-378 | ||

| Medium - M | 157 | 13-38 | 97-328 | ||

| Medium Fine - MF | 125 | 13-38 | 114-299 | ||

| Fine - F | 80 | 8-32 | 90-251 | ||

|

CH660 (DG500) |

Extra Coarse - EC | 321 | 16-51 | 177-662 | 315 |

| Coarse - C | 253 | 16-51 | 171-643 | ||

| Medium Coarse - MC | 198 | 16-44 | 162-552 | ||

| Medium - MF | 155 | 16-38 | 197-502 | ||

| Medium Fine - MF | 133 | 13-38 | 192-451 | ||

| Fine - F | 96 | 13-38 | 195-4 | ||

| Extra Coarse Cavity Type | |||||

|

CH420 (DG100S) |

Extra Coarse - EC | 267 | 22-38 | 85-168 | 160 |

| Coarse - C | 223 | 19-3 | 170-280 | ||

|

CHS430 (DG200S) |

Extra Coarse - EC | 320 | 25-54 | 126-344 | 160 |

| Coarse - C | 260 | 19-48 | 108-301 | ||

|

CHS440 (DG300S) |

Extra Coarse - EC | 400 | 29-51 | 267-601 | 250 |

| Coarse - C | 350 | 25-51 | 225-511 | ||

|

CHS660 (DG500S) |

Extra Coarse - EC | 622 | 41-83 | 349-1050 | 315 |

| Coarse - C | 556 | 38-70 | 318-892 | ||

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery