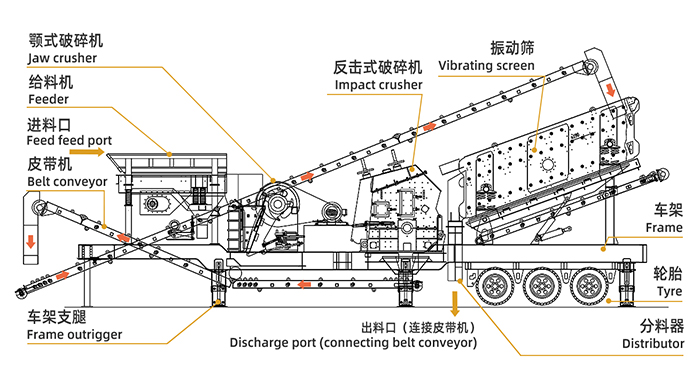

The jaw crusher + impact crusher four-combination mobile crushing station has been widely used in many industries such as mining, building materials, and solid waste treatment due to its advantages such as efficient crushing, flexible adaptability, energy saving, and economy, intelligent automation, and environmental protection and safety.

Mobile crushing and screening equipment is a modular mobile production line that integrates crushing, screening, and conveying functions. It is usually installed on tires or crawler chassis and can be flexibly transferred to other sites. Its core features are high integration and mobility. It does not require fixed infrastructure and can directly reach the raw material site or construction waste dump site to achieve "on-site material processing".

• Mobile equipment is mostly equipped with a combined crushing process of jaw crusher + impact crusher, which is suitable for materials with compressive strength ≤350MPa. The impact crushing principle of the impact crusher is more efficient for medium hardness stones.

• Mobile equipment can quickly enter the demolition site to achieve integrated crushing, screening, and iron removal (with magnetic separator) to produce recycled aggregates.

• Suitable for projects with dispersed sand and gravel mining sites and short mining cycles, avoiding high investment and site restrictions of fixed production lines.

Inapplicable scenarios: If ultra-high hardness stones (such as granite and basalt) need to be finely crushed, cone crushers are required, but mobile cone crushers are more expensive, and fixed production lines are usually more economical.

Modular Mobile Crushing Station

Construction Waste Crushing Equipment

Impact Crusher Mobile Crusher

Stone Crushing And Screening Machine

• The equipment can be put into production as soon as it arrives on site and connected to the power supply (or diesel engine drive), eliminating time-consuming links such as civil engineering and steel structure installation of fixed lines.

• Go directly to the raw material yard or construction waste site to reduce the material transportation distance (especially suitable for urban demolition projects).

• The host configuration can be freely adjusted according to the characteristics of the raw materials (such as pre-screening when the soil content is high) or the requirements of the finished product (multi-stage screening).

• The new equipment is equipped with spray dust reduction and closed structure, and some models support remote monitoring and automatic adjustment, which complies with environmental protection policies.

Reduce the operating load of the impact crusher: The coarse crushing effect of the jaw crusher breaks large pieces of material into smaller pieces, reducing the operating load of the impact crusher, thereby increasing the overall crushing power.

Optimize particle size distribution: The particle size distribution of the crushed product of the jaw crusher is relatively wide, while the impact crusher can further adjust and optimize the particle size distribution to ensure that the product particle size meets the requirements.

Improve overall crushing efficiency: The combined use can give full play to the advantages of the two crushers, improve the overall crushing efficiency, and shorten the crushing time.

| Model | YDPZ46-1007 | YDPZ46-900 | YDPZ57-1210 | YDPZ57-75 | YDPZ96-1214 | YDPZ96-160 |

| Vibrating Feeder | ZSW0625 | ZSW0625 | ZSW8530 | ZSW8530 | ZSW9638 | ZSW9638 |

| Primary Jaw Crusher | PE400×600 | PE400×600 | PE500×750 | PE500×750 | CJ96 | CJ96 |

| Feeding Size (mm) | ≤350 | ≤350 | ≤425 | ≤425 | ≤480 | ≤480 |

| Feeding Size (mm) | 15-60 | 15-60 | 40-130 | 40-130 | 60-160 | 60-160 |

| Secondary Crusher | Impact crusher | Cone crusher | Impact crusher | Cone crusher | Impact crusher | Cone crusher |

| Model | PF1007 | PYB900 | PF1210 | CS75 | PFW1214 | CS160 |

| Feeding Size (mm) | ≤250 | ≤115 | ≤400 | ≤150 | ≤430 | ≤205 |

| Capacity (t/h) | 15-60 | 15-90 | 70-130 | 27-163 | 100-180 | 109-349 |

| Vibrating Screen | 2/3/4YK1237 | 2/3/4YK1237 | 2/3/4YK1848 | 2/3/4YK1848 | 2/3/4YK1860 | 2/3/4YK1860 |

| Belt Conveyor | B500x8m | B650 | B650 | B650 | B800 | B800 |

| Capacity (t/h) | 15-60 | 15-60 | 60-100 | 100-150 | 150-180 | 180-300 |

| Overall Size(mm) | 11500*2050*5400 | 11500*2050*5400 | 15800*2300*5850 | 15800*2300*5850 | 18000*2700*7650 | 18000*2700*7650 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery