![]()

Kaolin, often called the "industrial MSG," plays an indispensable role in dozens of industries, including ceramics, papermaking, coatings, and rubber. However, naturally mined kaolin must undergo a series of meticulous processes to maximize its value. Grinding, as the core step in kaolin processing, directly determines the product's fineness, whiteness, and performance.

Modern kaolin grinding production lines have evolved from the traditional two-stage "coarse-fine" crushing process to a multi-stage, intelligent crushing system. The introduction of online particle size analyzers and automatic adjustment devices allows for particle size control with an accuracy of ±5%, significantly reducing energy consumption in subsequent grinding steps.

Kaolin raw materials typically contain 8-15% free moisture, and traditional drying methods consume over 30% of the total energy consumption of the entire production line. The newly developed "waste heat recovery + microwave-assisted" composite drying technology can achieve energy savings of 40% while also eliminating the particle agglomeration problem associated with traditional drying.

For kaolin products in different application areas, the choice of grinding equipment is becoming highly specialized:

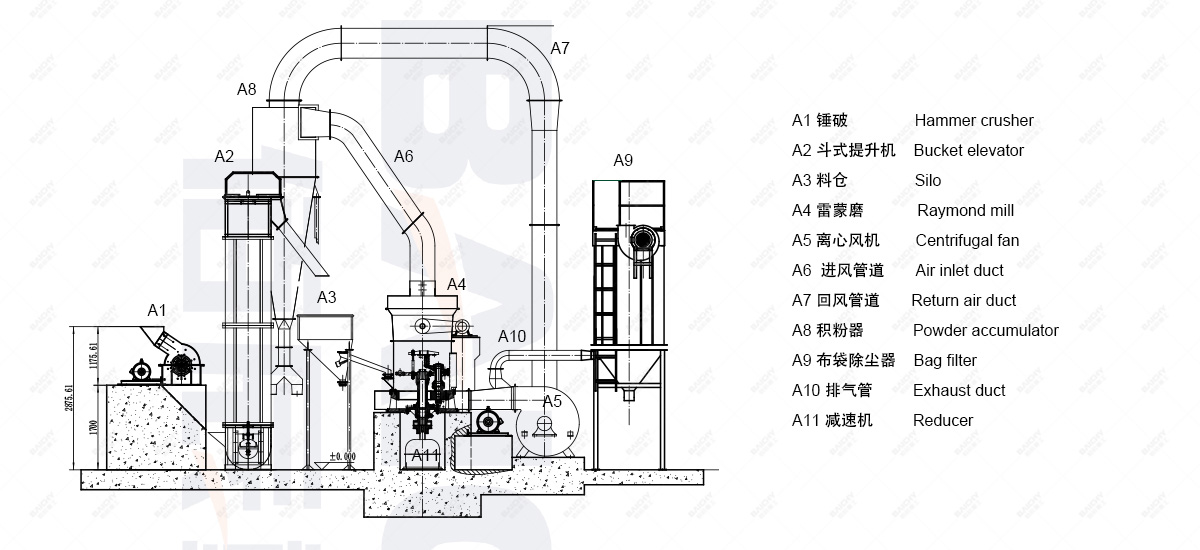

• Raymond mill: Suitable for general filler-grade products with mesh sizes of 400-800

• Vertical mill: The preferred choice for producing high-end coating-grade products with mesh sizes of 1250-3000

• Ball mill: Maintains an irreplaceable position in the ceramics industry

Precise fineness adjustment: from standard filler grade (400-800 mesh) to ultrafine powders (5000 mesh and above)

Real-time monitoring of motor load, air volume, and other data enables comprehensive energy savings of 20%-30%, reduces downtime, and increases equipment utilization to over 90%

Pulse bag dust removal (emissions <10mg/m³) + soundproof room design (noise <75dB)

Simultaneous organic coating (such as silane coupling agent treatment) during the grinding process

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery