Market prospects of stone crusher plants

With the rapid development of infrastructure construction, the demand for sand and gravel aggregates continues to grow. Building a modern stone crusher plant has become the choice of many investors. This article will give you a detailed introduction to the whole process of building a

stone crusher plant from scratch, including key links such as site selection, equipment selection, production line design, environmental protection measures and investment return analysis.

1. Preliminary preparation for the construction of a stone crusher plant

Project feasibility analysis

• Market demand research: Analyze the supply and demand of sand and gravel aggregates in the local and surrounding areas

• Raw material source assessment: Determine the source of stone (mining or construction waste recycling)

• Policy and regulatory review: Understand local environmental protection, land, safety production and other policy requirements

Key factors for site selection

• Geographical location: Close to the source of raw materials and sales market, convenient transportation

• Terrain conditions: Flat and open, with sufficient space for expansion

• Water and electricity supply: Ensure stable power supply and sufficient water source

• Environmental protection requirements: Far away from residential areas, in line with environmental assessment standards

Investment budget planning

• Small crushing plant (50 tons per hour): about 800,000-1.5 million yuan

• Medium-sized crushing plant (100-200 tons per hour): 1.5-5 million yuan

• Large crushing plant (more than 300 tons per hour): 5-20 million yuan

2. Crushing equipment selection guide

Mainstream crushing equipment comparison

| Equipment type |

Applicable materials |

Crushing ratio |

Capacity range |

Advantages and Disadvantages |

| Jaw Crusher |

Various Hardness Stones |

4-6 |

1-1000t/h |

Simple structure, easy maintenance, but uneven product size |

| Cone Crusher |

Medium and High Hardness Stones |

3-5 |

50-1500t/h |

High crushing efficiency, good product shape, but high investment |

| Impact Crusher |

Medium and Low Hardness Stones |

10-20 |

30-800t/h |

Excellent product shape, but fast consumption of wear-resistant parts |

| Hammer Crusher |

Low Hardness Brittle Materials |

10-15 |

5-300t/h |

One-time molding, but loud noise and dust |

Auxiliary Equipment Configuration

• Feeder: Uniform feeding, protection of crusher

• Vibrating screen: Grading and screening of products of different specifications

• Conveyor belt: Connecting various production links

• Dust removal equipment: Meet environmental protection requirements

• Control system: Automated production management

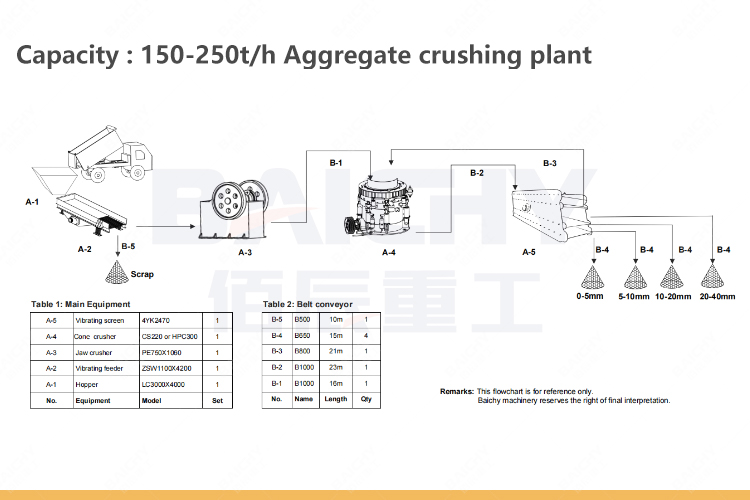

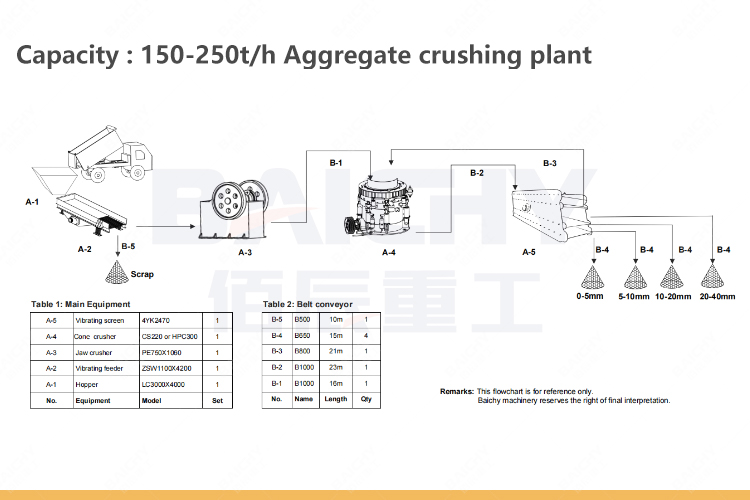

Production line configuration plan

• Primary crushing line: feeder + jaw crusher + cone crusher + screening

• Medium and fine crushing production line: impact crusher + vibrating screen + sand washer

• Mobile crushing station: flexible and suitable for temporary projects

3. Production line process design

Typical process

Raw materials → feeding → primary crushing → transfer silo → secondary crushing → screening → finished product silo

Main points of plant layout

• Raw material area: sufficient yard area, it is recommended to set up dustproof nets

• Production area: reasonable equipment spacing, leaving maintenance space

• Finished product area: classified stacking of products of different specifications

• Office area: keep a safe distance from the production area

Environmental design considerations

• Fully enclosed plant design

• Spray dust removal system

• Noise isolation measures

• Wastewater recycling system

4. Environmental protection and safety measures

• Environmental protection compliance plan

• Install bag dust collector (dust removal efficiency>99%)

• Build sedimentation tank to treat sand washing wastewater

• Set up soundproof walls to reduce noise pollution

5. Investment cost and return analysis

Investment composition

• Equipment purchase: about 50-60% of the total investment

• Plant construction: 20-25%

• Environmental protection facilities: 10-15%

• Other costs: 5-10%

Operating costs

• Electricity: about 1-2 yuan/ton

• Labor: 3-5 people, monthly total cost about 20,000-40,000 yuan

• Replacement of wearing parts: about 0.5-1 yuan/ton

• Maintenance: 2-3% of annual equipment value

Return on investment cycle

• Small plant: usually 1-2 years

• Medium-sized plant: 1.5-3 years

• Large plant: 2-4 years

6. FAQ

Q1: What approval procedures are required to build a stone crusher plant?

A: Usually you need to apply for a business license, environmental impact assessment approval, safety production license, mining license (such as self-provided mines), etc.

Q2: How to choose suitable crushing equipment?

A: It is necessary to consider factors such as raw material hardness, output requirements, product specifications and budget. It is recommended to consult a professional equipment supplier.

Q3: How long does it take to build a crushing plant?

A: From site selection to production, it takes about 3-6 months for a small plant, 6-12 months for a medium-sized plant, and 1-2 years for a large plant.

Q4: How to improve the production efficiency of the crushing plant?

A: Optimize the process flow, select suitable equipment, perform regular maintenance, train operators, etc.

Building an efficient and environmentally friendly stone crusher plant requires comprehensive planning and professional execution. The plant construction guide provided in this article covers the key links from preliminary preparation to production and operation. It is recommended that investors consult professional engineers before the project starts, conduct detailed feasibility studies and personalized scheme design to ensure the smooth implementation of the project and obtain the expected returns.

For more professional advice or equipment selection services, please contact our technical team, and we will provide you with one-to-one plant construction consulting services.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Further reading: