The crusher is specially used for fine crushing of coal to produce ≤10mm or ≤3mm finished products. It has outstanding advantages for dealing with damp and easy plugging materials.

Reversible hammer crusher is a highly efficient and multi-purpose crushing equipment, mainly used for coarse and medium crushing of medium hardness and brittle materials.

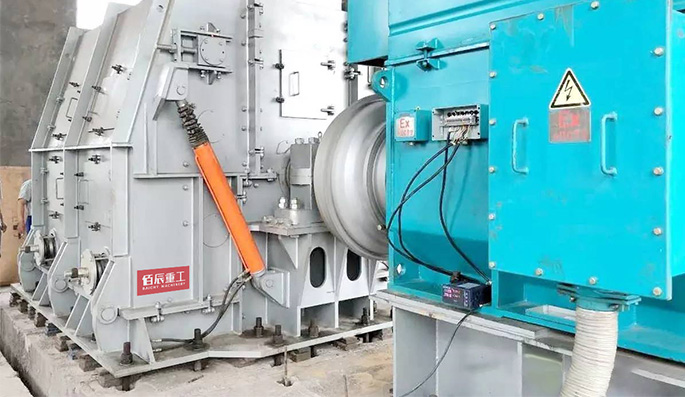

Reversible Hammer Crusher is an efficient and durable crushing equipment, mainly used for medium and fine crushing of medium hardness and brittle materials (such as limestone, coal silica, gypsum, etc.). Its core feature is that the rotor can rotate forward and reverse, which prolongs the service life of the hammer head, improves the crushing efficiency, and reduces the problem of material blockage.

• Bidirectional crushing: The rotor can rotate forward and reverse, the hammer head wears evenly on both sides, and the service life is increased by 30%-50%.

• Energy-saving: One machine completes multi-stage crushing, reducing equipment investment and energy consumption.

• Anti-blocking design: Suitable for sticky and wet materials (water content ≤15%), and automatically clears the blockage during reversal.

• Adjustable particle size: The discharge fineness is controlled by adjusting the gap between the impact plate (10-50mm) and the bar screen.

• Easy maintenance: Symmetrical hammer design, easy replacement, and reduced downtime.

Wear-Resistant Hammer Crusher

Gangue Crushing Equipment

Arge Hammer Crusher Manufacturer

Reversible Hammer Crusher

Reversible hammer crusher and heavy hammer crusher are both common types of hammer crushers, but they have significant differences in structure, working principle, and applicable scenarios.

The reversible hammer crusher adopts a bidirectional rotating rotor, and the hammer head can be used in forward and reverse rotation. It has stronger wear resistance and is suitable for medium and fine crushing of medium-hardness brittle materials (such as limestone and coal gangue), and can handle sticky and wet materials;

The heavy hammer crusher adopts a unidirectional rotating heavy integral hammer head, which has greater impact force and is suitable for coarse crushing of high-hardness materials (such as granite and iron ore). It has higher production capacity but faster wear. The reversible hammer crusher has a finer and adjustable discharge particle size and lower maintenance cost; the heavy hammer crusher is known for its large feed particle size (≤1200mm) and high output, but has higher energy consumption and maintenance costs.

Reversible hammer crusher has become one of the mainstream crushing equipment in mining, building materials, metallurgy and other industries due to its advantages of long life, high output and low maintenance.

Reversible hammer crusher features large impact force and high efficiency of crushing, it is widely used in power, metallurgy, construction material, the chemical industry, etc. for fine crushing of coal and rock with hardness less than 150MPa.

The crusher is specially used for fine crushing of coal to produce ≤10mm or ≤3mm finished products. It has outstanding advantages for dealing with damp and easy plugging materials.

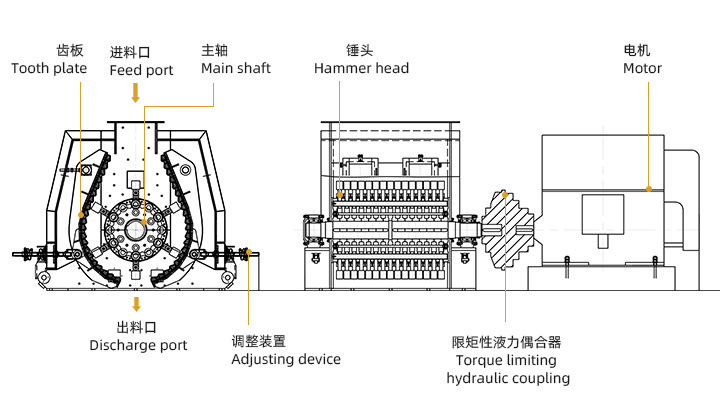

• The material enters the crushing chamber from the feed port, and the high-speed rotating rotor drives the hammer to perform the first impact crushing on the material.

• After the hammer collides with the material, the material is crushed or thrown onto the impact plate on the inner wall of the crusher for further crushing.

• When one side of the hammer is worn, the other side of the hammer can be reversed to continue working without immediately replacing the hammer, which significantly improves the equipment utilization rate.

• The crushed material is discharged through the gap of the sieve plate at the bottom, and the particle size is controlled by the sieve plate aperture (usually 3~30mm).

• Substandard materials continue to remain in the chamber until they are repeatedly crushed to a qualified size by the hammer.

| Model | Rotor Size(mm) | Feed Size(mm) | Finished Size(mm) | Production Capacity(t/h) | Power(kw) |

| PCK0808 | φ800×800 | ≤60 | ≤15mm | 25-40 | 90 |

| PCK1010 | φ1000×1000 | ≤80 | 35-70 | 110 | |

| PCK1012 | φ1000×1250 | ≤80 | 70-90 | 132 | |

| PCK1212 | φ1250×1250 | ≤100 | 90-120 | 220 | |

| PCK1214 | φ1250×1400 | ≤100 | 120-150 | 250 | |

| PCK1416 | φ1400×1600 | ≤120 | 160-250 | 355 | |

| PCK1418 | φ1400×1800 | ≤120 | 250-300 | 400 | |

| PCK1618 | φ1600×1800 | ≤140 | 280-350 | 560 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery