|

Equipment configuration

|

Vibr ating feeder ZSW850x3000 | PE500x750 Jaw crusher |CS75Cone crusher | YK1548 series Vibrating screen | Belt Conveyor. |

|

Raw materials

|

Crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials. |

|

Feed Size

|

Less than 425mm |

|

Capacity

|

80-100t/h |

|

Finished product

|

3-100mm |

|

Design requirements

|

1. The required production capacity 2. The type, hardness, and abrasiveness grade of the crushed material 3. The maximum size of the feed 4. The size of the desired final fraction |

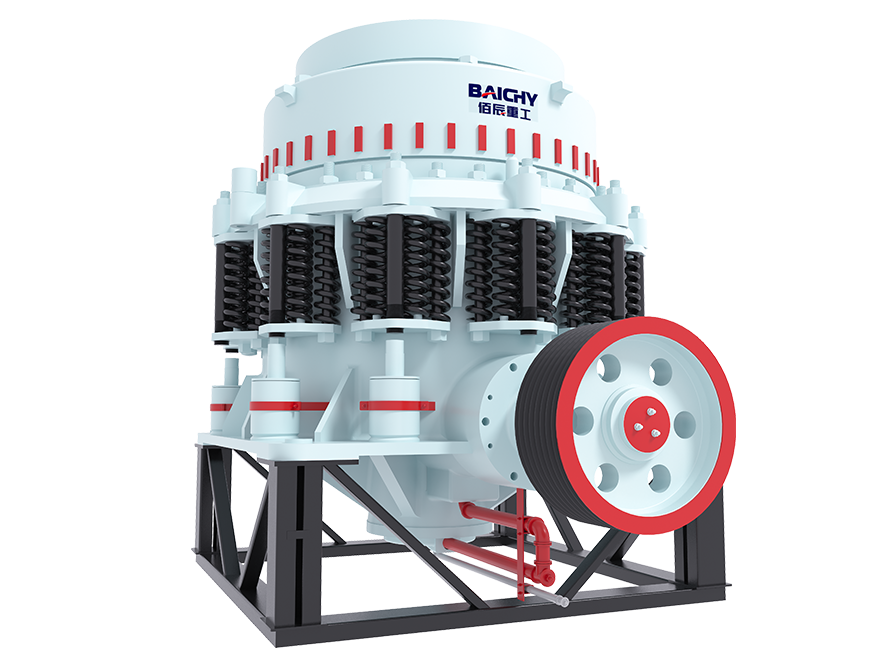

CS Symons cone crusher is a high-performance cone crusher. It is a modern high-performance crusher designed and developed based on the principle of laminated crushing and the concept of more crushing and less grinding, based on the introduction and absorption of foreign technology, according to customer needs.

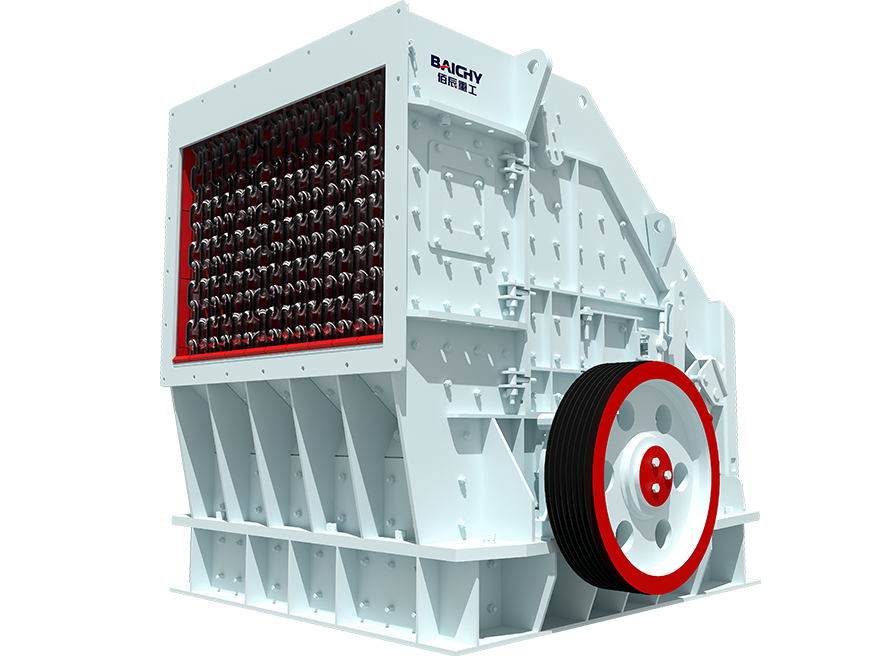

The CI series impact crusher is a highly efficient and energy-saving crushing equipment designed specifically for sand production and material shaping. It features a large feed size, high crushing efficiency, excellent product particle shape, and long service life of wear parts. It is widely used in various fields such as ore crushing, manufactured sand production, and construction aggregate processing.

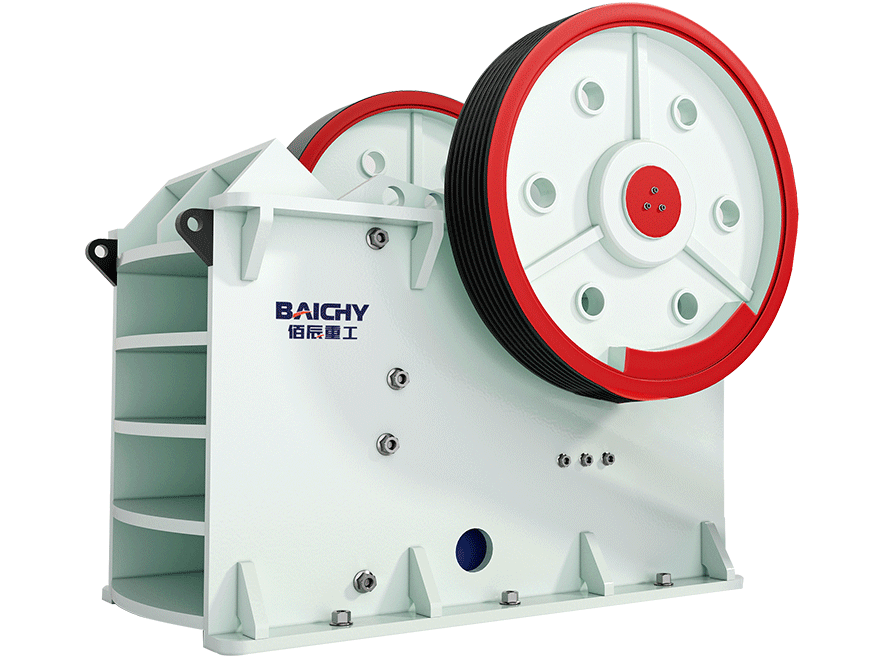

• Processing capacity: Theoretical output 40-110t/h (adjusted according to material hardness and feed particle size), suitable for primary crushing, can process hard rock ≤425mm (such as granite, basalt).

• Advantages: Hydraulic overload protection can indeed improve safety, but it should be noted that its discharge port range (50-100mm) may require a subsequent cone crusher for further crushing.

• Recommendation: If the raw material contains more clay or moisture, it is recommended to add a vibrating feeder or grate screen for pre-screening to avoid blockage of the jaw crusher.

• CSB75 (standard type): suitable for medium crushing, discharge size 16-38mm, processing capacity about 45-91t/h;

• CSD75 (short head type): suitable for fine crushing, discharge size 3-16mm, processing capacity about 27-90t/h.

• If the finished product requires ≤30mm, CSB75 is preferred; if ≤20mm is required, CSD75 must be used or the discharge port must be adjusted.

• Cone crusher is sensitive to the moisture content of the material (recommended <5%), wet material is prone to blockage, and needs to be controlled in advance.

The four-combination mobile station is widely used in various engineering projects due to its high flexibility, customizability, and efficiency. It can quickly adapt to different working environments and needs, provide efficient and accurate crushing and screening services, and provide strong support for the smooth progress of various engineering projects.

Impact crushers - high-quality impactors, Rock Crushing & Screening Plants, Crushing And Screening Plant, Stone Crusher For Sale

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.