The double-roller crusher has significant advantages in the crushing industry, and these advantages make it an ideal choice in a variety of application scenarios.

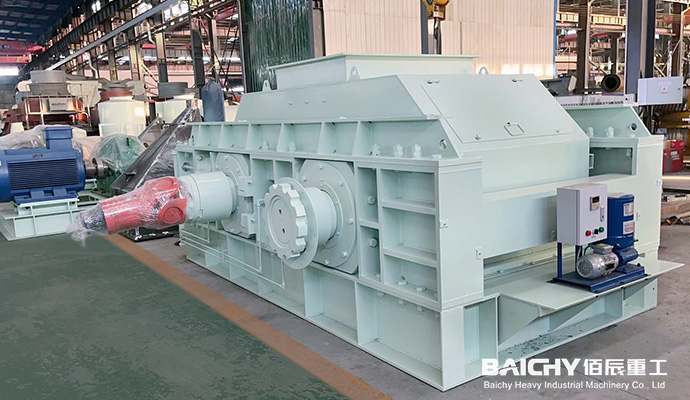

The double roll crusher, also known as a twin-roll crusher, is a high-efficiency crushing equipment composed of two counter-rotating crushing rollers. Material enters from the top between the two rollers and is crushed by compression, shearing, and splitting forces. This equipment uses high-quality alloy wear-resistant roller shells, ensuring a long service life. The crushing ratio is adjustable, and the output particle size is uniform. It is widely used in the coarse and fine crushing of various medium-hardness materials.

1. Frame: Made of high-strength steel, supporting the entire equipment structure.

2. Crushing Rollers: The core working components, including a fixed roller and a movable roller, with wear-resistant roller shells on the surface.

3. Transmission Device: Includes motor, reducer, coupling, gears, etc., providing crushing power.

4. Adjustment Device: Hydraulic or spring system, used to adjust the gap between the two rollers and control the output particle size.

Smooth Roll Crusher

double roller crusher

roller crusher

stone crusher

1. Simple structure, easy maintenance: The entire machine has a compact structure, occupies a small area, and requires simple daily maintenance and low maintenance costs.

2. Adjustable particle size, uniform output: By adjusting the gap between the two rollers, the output particle size can be controlled to meet different production needs.

3. Overload protection, safe and reliable: Equipped with a hydraulic or spring adjustment device, it can automatically retract when encountering uncrushable objects, protecting the equipment.

4. Wear-resistant and durable, stable operation: The roller surface is made of high wear-resistant alloy material, ensuring a long service life and stable and reliable equipment operation.

Roller crushers are used in mining to crush ores of various hardnesses, such as limestone, granite, iron ore, etc. Whether it is an open-pit mine or an underground mine, roll crushers can perform crushing operations well to meet the needs of mining production.

The working principle of a double-roll crusher is based on the crushing of materials by two counter-rotating crushing rollers:

1. The material falls into the gap between the two rollers from the feed opening.

2. Under the action of friction and gravity, the material is drawn into the crushing chamber.

3. The two rollers rotate in opposite directions, generating strong compressive and shearing forces on the material.

4. The material is crushed under pressure, and after reaching the desired particle size, it is discharged from below.

5. The gap between the two rollers determines the size of the output particles, and this gap can be adjusted by an adjustment device.

| Model | Roller Diameter (mm) |

Roller Length (mm) |

Feeding Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

| 2PG-400X250 | 400 | 250 | ≤ 25 | 2-10 | 2*5.5 |

| 2PG-610X400 | 610 | 400 | ≤ 30 | 5-20 | 2*15 |

| 2PG-610X750 | 610 | 750 | ≤ 30 | 5-25 | 2*18.5 |

| 2PG-750X400 | 750 | 400 | ≤ 30 | 10-40 | 2*18.5 |

| 2PG-800X600 | 800 | 600 | ≤ 40 | 12-50 | 2*22 |

| 2PG-800X800 | 800 | 800 | ≤ 40 | 20-60 | 2*22 |

| 2PG-900X900 | 900 | 900 | ≤ 50 | 50-100 | 2*37 |

| 2PG-1200X900 | 1200 | 900 | ≤ 50 | 60-130 | 2*45 |

| 2PG-1200X1200 | 1200 | 1200 | ≤ 50 | 80-150 | 2*45 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery