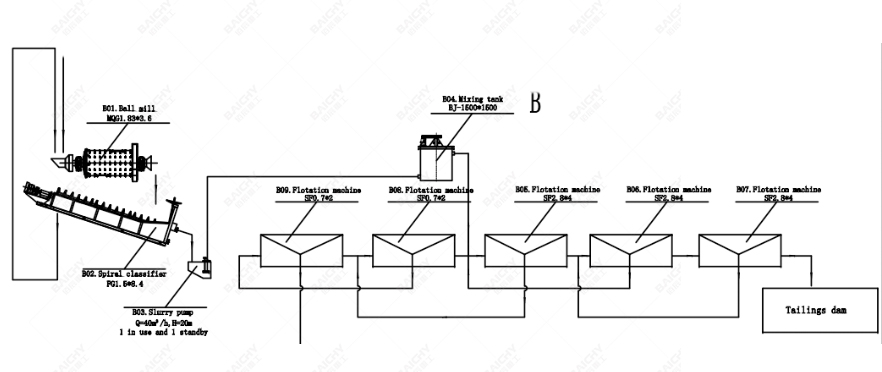

Gold ore concentrator (Gold Ore Concentrator) is a professional equipment for extracting gold, suitable for various scenarios such as placer gold, rock gold, and tailings recovery. Through gravity separation, centrifugal separation, flotation and other processes, gold particles are efficiently enriched and the recovery rate of ore dressing is improved.

Gold ore concentrator mainly adopts gravity separation method, using the high density characteristics of gold, and achieves efficient separation through the following steps:

• Feed crushing: The raw ore enters the gold concentrator after crushing.

• Gravity separation: Through centrifuges, shakers, chutes and other equipment, the gold particles are settled and enriched.

• Concentrate collection: The gold concentrate is separated and the tailings are discharged.

• Further purification (optional): The amalgamation method and cyanidation method are used to improve the purity of gold.

Gold Ore Gold Selection Machine

Gold Selection Equipment

Gold Extraction Equipment

Placer Gold Extraction Equipment Manufacturers

✔ High recovery rate (more than 98%): Using advanced centrifugal technology, gold extraction is more thorough.

✔ Energy saving and environmental protection: low energy consumption, no chemical pollution, in line with mining environmental protection standards.

✔ Automated operation: PLC control system, reducing manual intervention.

✔ Customized solution: Provide exclusive equipment according to the ore type (placer gold/rock gold/tailings).

It is recommended to use the centrifugal + shaking table combination process, the recovery rate can reach more than 95%.

Our gravity gold separator does not require cyanide, pure physical separation, safer and more environmentally friendly.

Gold concentrators are designed to focus on finding fine gold particles that would otherwise be missed.

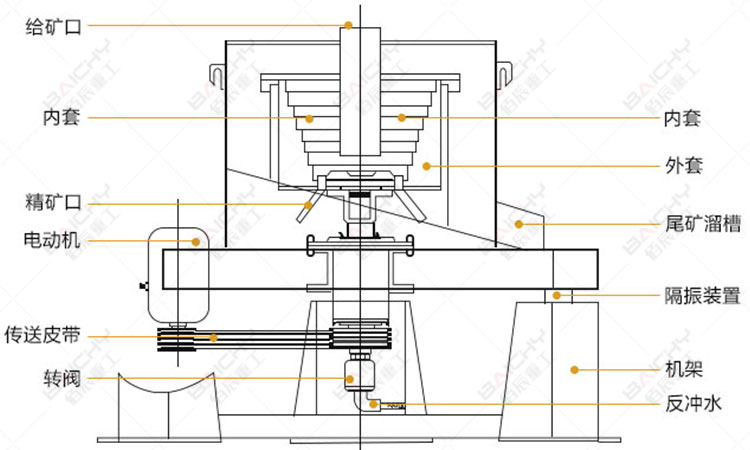

The gold selection machine adopts a reasonable structural design, with a small footprint, simple installation and easy operation.

The gold selection machine has a high processing capacity and recovery rate, which can greatly improve the efficiency of gold mining. At the same time, the equipment has low energy consumption during operation, which helps to reduce production costs.

The gold selection machine has a high separation accuracy, which can effectively separate gold from ore and improve the grade of gold.

The gold selection machine pays attention to environmental performance during the design and manufacturing process, and adopts noise-free and pollution-free processes and materials to reduce pollution to the environment.

The working principle of the gold concentrator is mainly based on physical separation technology. The separation of light and heavy minerals is achieved through the combined effect of high-speed rotating centrifugal force and fluidized backwash water. In the mineral processing process, the ore is crushed, ground and classified before entering the mineral processing part of the gold concentrator. Under the action of high-speed rotating centrifugal force, light minerals are thrown out, while heavy minerals (including gold) are deposited in specific areas of the mineral processing part, thereby achieving the separation of gold ore and impurities.

| Model | BC-19 | BC-30 | BC-60 | BC-80 | BC-100 |

| Capacity(t/h) | 0.25-0.3 | 2-3 | 10-15 | 35-40 | 80-120 |

| Feeding size(mm) | 0-3 | 0-4 | 0-6 | 0-6 | 0-6 |

| Feeding density(%) | 0-50 | ||||

| Fludization water(m³/h) | 2-3 | 3-5 | 7-10 | 30-36 | 50-60 |

| Concentrate capacity(kg/time) | 2-3 | 10-20 | 30-40 | 60-70 | 70-80 |

| Power (kw) | 0.75 | 1.5 | 5.5 | 11 | 18.5 |

| Overall Size (mm) | 790*785*790 | 1180*1140*1250 | 1970*1670*1750 | 2300*1800*2200 | 2500*2000*2400 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery