The YK series vibrating screen is a highly efficient and versatile screening equipment, widely used for screening, grading, and impurity removal of various granular materials.

The YK series circular vibrating screen adopts advanced German technology and Japanese process standards, featuring high screen strength, stable operation, and low noise. Its vibration trajectory is circular, and the amplitude can be adjusted by regulating the excitation force, thus efficiently completing various screening operations. This series of equipment features high screening accuracy, large processing capacity, robust and durable structure, and convenient maintenance, making it an indispensable key equipment in modern production lines.

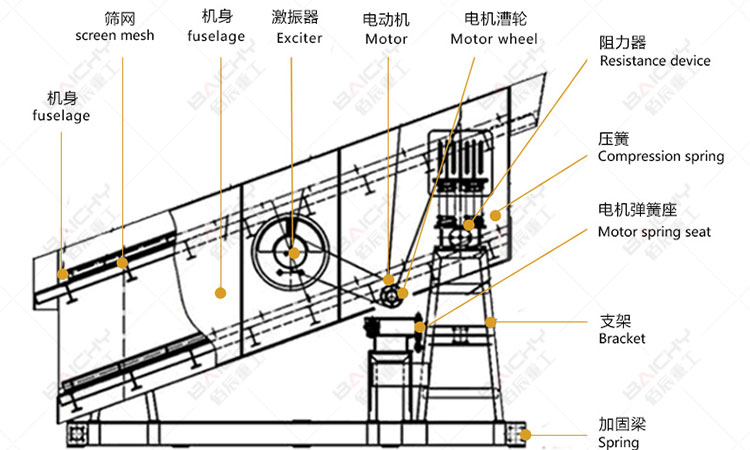

• Screen Box: The main structure composed of side plates, beams, and reinforcing ribs, with high strength and strong load-bearing capacity.

• Vibrator (Exciter): The core power source, consisting of bearings, main shaft, eccentric blocks, and bearing seats, generating the required excitation force.

• Damping System: Mainly composed of helical springs or rubber springs, supporting the screen body and reducing the dynamic load transmitted to the foundation.

• Screen Mesh and Tightening Device: Multi-layer screen meshes with different apertures, fixed by wooden wedges or bolt tensioning devices for easy replacement.

• Drive Motor: Provides power to the equipment, usually driving the exciter directly through a flexible coupling or V-belt.

Vibrating Screen for Concrete

Vibrating Screen for Limestone

Vibrating Screen for Riverstone

Vibrating Screen for Stone

1. High Screening Efficiency and Excellent Output: Using high-strength ring groove rivets for connection, the box body has high strength; the large amplitude and high vibration intensity design allow materials to pass through the screen quickly, increasing screening efficiency by more than 15%, and the output is significantly higher than similar products.

2. Durable and Easy to Maintain: The side plates, beams, and exciter base are connected with high-strength bolts, resulting in a stable structure and strong fatigue resistance. The bearing seat adopts a labyrinth seal, effectively preventing dust and extending the bearing life. Lubrication points are concentrated, making daily maintenance simple and quick.

3. Stable Operation and Low Noise Pollution: The optimized damping spring system effectively isolates the impact of the equipment on the foundation. The equipment runs smoothly, with low working noise, meeting environmental protection requirements.

4. Strong adaptability and flexible configuration: It can be equipped with 1-4 layers of screens, allowing for the simultaneous classification of materials of various sizes. The screens can be made of various materials such as polyurethane, manganese steel, and stainless steel, adapting to different material characteristics and working conditions.

YK series vibrating screens are widely used in many industries such as ore dressing, coal dressing, building materials, power, and chemical industry. Its diverse models and specifications can meet the production needs of different users. Whether it is a large production line or a small production line, you can find a suitable YK series vibrating screen model.

1. Power Drive: The motor drives the exciter's main shaft to rotate at high speed via a belt, generating a strong vibration force from the eccentric block.

2. Screen Body Vibration: The vibration force compels the screen box to vibrate in a continuous circular trajectory under the support of springs.

3. Material Screening: The material is continuously thrown up and down on the screen surface, and fine particles are separated by passing through the screen during the bouncing motion.

4. Material Flow Output: Under the action of vibration and the screen surface inclination angle, the coarse material that does not pass through the screen moves forward and is discharged from the end, achieving continuous classification.

| Model | Sieve specification (mm) | layer | Mesh size (mm) | Max feeding size (mm) | Processing capacity (t/h) | Moto power (kw) | Vibrating Frequency (r/min) | Double amplitude (mm) |

| 2YK1237 | 1200X3700 | 2 | 3-50 | 200 | 30-100 | 5.5 | 970 | 5-9 |

| 3YK1237 | 1200X3700 | 3 | 3-50 | 200 | 30-100 | 7.5 | ||

| 2YK1548 | 4800X1500 | 2 | 3-100 | 400 | 30-275 | 15 | ||

| 3YK1548 | 4800X1500 | 3 | 3-100 | 30-275 | 15 | |||

| 2YK1848 | 4800X1800 | 2 | 3-100 | 56-330 | 18.5 | |||

| 3YK1848 | 4800X1800 | 3 | 3-100 | 56-330 | 18.5 | |||

| 4YK1848 | 4800X1800 | 4 | 3-80 | 56-330 | 22 | |||

| 2YK1860 | 6000X1800 | 2 | 3-100 | 65-586 | 18.5 | |||

| 3YK1860 | 6000X1800 | 3 | 3-100 | 65-586 | 22 | |||

| 4YK1860 | 6000X1800 | 4 | 3-100 | 65-586 | 30 | 980 | ||

| 2YK2160 | 6000X2100 | 2 | 3-100 | 81-720 | 22 | 980 | ||

| 3YK2160 | 6000X2100 | 3 | 3-100 | 81-720 | 30 | 970 | ||

| 4YK2160 | 6000X2100 | 4 | 3-100 | 81-720 | 37 | 980 | ||

| 2YK2460 | 6000X2400 | 2 | 3-150 | 100-810 | 22 | 970 | ||

| 3YK2460 | 6000X2400 | 3 | 3-150 | 100-810 | 30 | 980 | ||

| 4YK2460 | 6000X2400 | 4 | 3-150 | 150-850 | 37 | 980 | ||

| 2YK2470 | 7000X2400 | 2 | 3-100 | 180-900 | 30 | 980 | ||

| 3YK2470 | 7000X2400 | 3 | 3-100 | 180-900 | 37 | 980 | ||

| 4YK2470 | 7000X2400 | 4 | 3-100 | 180-900 | 45 | 980 | ||

| 2YK2480 | 8000X2400 | 2 | 3-150 | 190-940 | 30 | 980 | ||

| 3YK2480 | 8000X2400 | 3 | 3-150 | 190-940 | 37 | 980 | ||

| 4YK2480 | 8000X2400 | 4 | 3-150 | 190-940 | 45 | 980 | ||

| 2YK3070 | 7000X2400 | 2 | 3-100 | 220-1000 | 37 | 980 | ||

| 3YK3070 | 7000X2400 | 3 | 3-150 | 220-1000 | 45 | 980 | ||

| 4YK3070 | 7000X2400 | 4 | 3-150 | 220-1000 | 55 | 980 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery