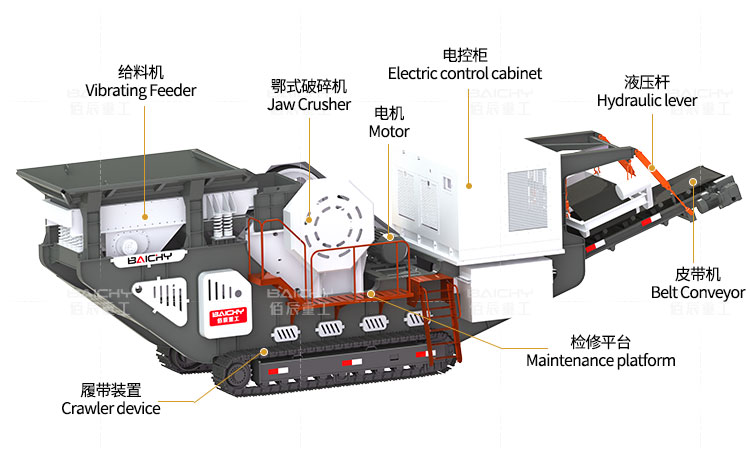

The Track-mounted Mobile Jaw Crusher is a high-performance mobile crushing equipment integrating feeding, crushing, and conveying. It adopts a fully hydraulic drive system and is equipped with a heavy-duty tracked chassis, possessing strong off-road capability and site adaptability. The equipment adopts a modular design, allowing for rapid site relocation and deployment, significantly improving operational efficiency.

Tracked mobile jaw crusher

mobile crushing plant

jaw crusher equipment

construction waste processing equipment

1. High Mobility and Flexibility: Heavy-duty tracked chassis design allows for flexible steering, adaptability to complex terrain, and convenient relocation.

2. Integrated Intelligent Control: Integrates feeding, crushing, screening, and conveying systems, equipped with an intelligent control system.

3. Energy Saving and Environmental Protection: Optimized crushing chamber design results in low energy consumption, equipped with comprehensive dust removal and noise reduction devices.

4. Rapid Deployment and Operation: No foundation construction is required after the equipment arrives on site; it can be quickly put into production.

The Track-mounted Mobile Jaw Crushers are widely used in mining, demolition sites, road construction, and other mobile crushing operations that require frequent relocation, and are particularly suitable for crushing operations in complex terrain conditions.

The Track-mounted Mobile Jaw Crusher is designed to crush materials nearby, providing customers with convenient, efficient, and low-cost installation. According to the requirements of different crushing processes, the program of crushing first and then sieving or first sieving and then crushing can be selected, which is flexible in use and can meet the needs of customers to the greatest extent.

Vibrating feeders allow for optimal pre-scaling and uniform feeding. The crusher can be equipped with Jaw Crusher, Impact Crusher, Cone Crusher, VSI Crusher, etc. A diesel direct drive is combined with an electric motor for maximum performance in a small space. Optional magnetic separator, unloading belt, and water spray system.

| Model | Feeder | Jaw Crusher | Main Discharge Belt | Side Discharge Belt | Capacity |

|---|---|---|---|---|---|

| YMC80 | G2D8035 | C80 | B800x9m | B500x3.8m | 80-125t/h |

| YMC96 | G2D9638 | C96 | B1000x12m | 100-250t/h | |

| YMC106 | G2D1142 | C106 | 160-360t/h | ||

| YMC116 | C116 | B1200x13m | 200-450t/h | ||

| YMC120 | G2D1242 | C120 | 300-520t/h |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery