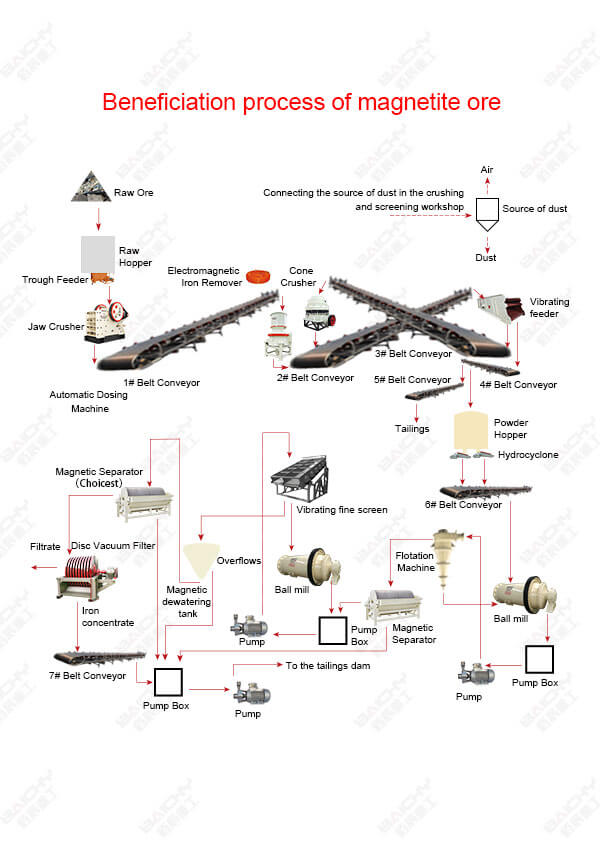

• The purpose is to control the particle size of the raw ore within a suitable range for subsequent processing.

• Commonly used crushing equipment includes jaw crushers and cone crushers.

• The crushing process may include two stages: coarse crushing and fine crushing, to ensure that the ore particles reach a size suitable for magnetic separation.

• The magnetic properties of magnetite are used to separate it from non-magnetic minerals through magnetic separation equipment.

• Magnetic separation equipment such as magnetic separators and wet magnetic separators separate ore particles by adjusting the strength of the magnetic field and the rotation speed according to the size of ore particles and the magnetic differences in the ore.

• The ore after magnetic separation may need to undergo a gravity separation process to further improve the grade and recovery rate of magnetite.

• Gravity separation equipment such as spiral classifiers and spiral ore washers separate the mud and particles in the ore again by setting appropriate inclination angles and rotation speeds.

• Dehydration is the process of removing water from magnetite, with the aim of reducing transportation costs and energy consumption for subsequent processing.

• Dehydration can be carried out by centrifuges, vacuum filters and other equipment.

• Concentrate treatment is the process of further refining and purifying the obtained magnetite products.