There are many types of mining magnetic separators, including wet magnetic separator, dry magnetic separator, high gradient magnetic separator, etc. Among them, wet magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size below 3mm; dry magnetic separator is suitable for separation of magnetic minerals under dry conditions; high gradient magnetic separator is suitable for separation of weak magnetic minerals.

Magnetic Separator - Complete Conveyor Solutions

Magnetic Separator - Complete Conveyor Solutions

Magnetic Separator - Complete Conveyor Solutions

Magnetic Separator - Complete Conveyor Solutions

To enable different levels of separation from a wide range of materials, there is an extensive range of different Magnetic Separator designs.

According to the different stages and needs of ore sorting, mining magnetic separators are divided into various types, such as pre-selection, roughing, and concentrating, to meet the processing needs of different ores.

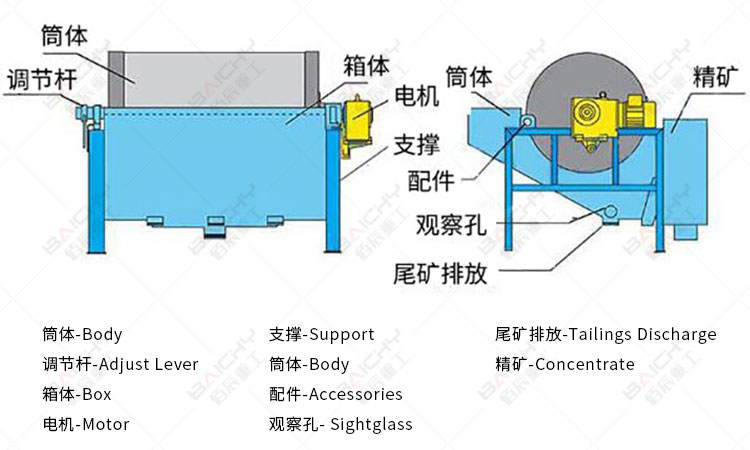

The mining magnetic separator adopts advanced magnetic circuit design, with uniform magnetic force distribution, large magnetic penetration depth, and high recovery rate. The multi-pole structure helps to improve the grade of concentrate.

High magnetic field strength, such as the magnetic field strength of the permanent magnetic separator can reach 1650mT, ensuring efficient magnetic separation effect.

The magnets of the mining magnetic separator are fixed by bolts and wrapped with stainless steel straps, ensuring that the magnets will not fall off during permanent use, increasing the stability and reliability of the equipment.

The tank structure of the mining magnetic separator is reasonable, which is conducive to the passage of slurry and avoids blockage. Slag discharge mechanisms are provided at both ends for easy maintenance and cleaning.

1. Magnetic field generation: The mining magnetic separator is equipped with a strong magnetic field source, which is usually achieved through permanent magnets or electromagnets. These magnetic field sources can generate strong magnetic fields to separate mineral particles with different magnetic properties.

2. Material transportation: The ore material to be processed is evenly transported to the working area of the magnetic separator through the feeding device. This working area is located in the magnetic field area inside the magnetic separator.

3. Magnetic separation: When the material passes through the magnetic field area, the magnetic mineral particles are attracted by the magnetic field and adsorbed to the magnetic components of the magnetic separator (such as magnetic drums, magnetic plates, etc.). Non-magnetic or weakly magnetic mineral particles are not affected by the magnetic field and continue to flow according to the original motion trajectory, thereby achieving the separation of magnetic minerals from non-magnetic minerals.

4. Magnetic material collection: The magnetic minerals adsorbed on the magnetic components can be collected by mechanical devices (such as scrapers, belts, etc.) for subsequent processing or recycling.

5. Discharge of non-magnetic materials: Non-magnetic or weakly magnetic mineral particles are discharged through the outlet of the magnetic separator to complete the entire sorting process.

6. Magnetic field adjustment: For some types of magnetic separators (such as electromagnetic separators), the strength of the magnetic field can be controlled by adjusting the current. This allows the operator to adjust the magnetic field strength according to the specific characteristics of the ore and the sorting requirements to achieve the best sorting effect.

7. Continuous operation: Mining magnetic separators are usually designed for continuous operation, which can continuously process large amounts of ore materials and improve production efficiency.

| Model | Magnetic field intensity (oe) | Capacity (t/h) | Power (kw) |

| CTB600X900 | 1450 | 8-15 | 1.1 |

| CTB600X1800 | 1500 | 15-25 | 2.2 |

| CTB750X1800 | 1550 | 30-45 | 3 |

| CTB900X1800 | 1650 | 35-60 | 4 |

| CTB1050X2400 | 1650 | 60-95 | 5.5 |

| CTB1200X3000 | 1650 | 80-150 | 7.5 |

| CTB1500X3000 | 1650 | 120-200 | 11 |

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery