Ball mill is a core equipment used in mineral processing. It is mainly used to grind ore into fine powder through mechanical force to release target metal particles (such as gold, silver, copper, iron, etc.), thereby improving the efficiency of subsequent extraction processes.

A ball mill is a cylindrical rotating device with steel balls or other grinding media inside. It crushes and grinds the ore through the impact force, friction, and gravity generated by the rotation of the cylinder.

Crushing and Grinding: Crushing the ore to the target particle size (usually 0.074-0.89mm) to release metal particles.

Even Mixing: Ensure that the ore is in full contact with chemical reagents (such as leaching agents).

Cost Control: Reduce energy consumption and operating costs through efficient grinding.

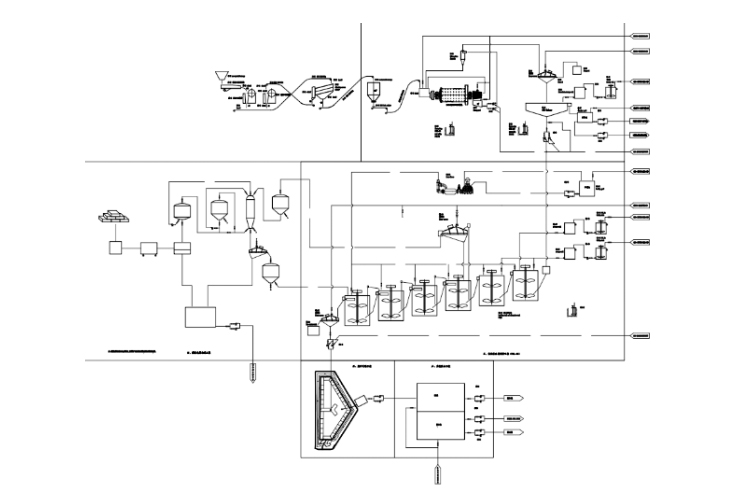

gold ore processing plant

ore ball mill

Inner wall lining

Ball mill steel balls

Impact crushing: The steel balls are carried to a high place by the cylinder and then fall down, hitting the ore to achieve coarse crushing.

Friction grinding: The rolling friction between the steel balls and the ore further refines the particles.

Wet ball mill: Add water to form a slurry, suitable for processes that require subsequent leaching or flotation (such as gold mines).

Dry ball mill: A waterless environment, suitable for water-sensitive minerals or direct drying of finished products.

Traditional structure, large processing capacity (0.18-90 tons/hour), suitable for large-scale ore processing.Various models (such as φ1500×5700, φ2100×4500) can be matched with rubber, ceramic, or steel liners.

Gold mines: Grind to a micron level to increase cyanide leaching rate.

Iron ore/copper ore: crushed to 0.074-0.4mm for magnetic separation or flotation.

Non-metallic minerals and industrial materials: preparation of coal powder, cement, and glass raw materials.

Stone crusher is used for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate, etc. Different final output sizes could meet your different needs.

Optimize the design of lining and grinding media, accurately grind to 0.074-0.4mm (200-400 mesh), suitable for flotation, leaching, and other processes. Variable frequency speed regulation technology flexibly responds to the needs of ores of different hardness, such as gold, copper, and iron ore.

(Compared with traditional equipment), with hydraulic coupling/permanent magnet motor to reduce energy consumption; automatic lubrication system to extend bearing life by more than 2 times, lower operating costs.

Freely switch to handle complex ores such as clay-type gold ores or dry quartz sand; anti-corrosion lining (rubber/high chromium alloy) resistant to acidic environment, reducing maintenance downtime.

Real-time monitoring of load and temperature to avoid bloating or idling; modular design to improve maintenance efficiency, annual operation rate exceeds 95%, stable and reliable.

The drum of the ball mill starts to rotate. This action is driven by the motor and the reducer, and the drum is driven by the large and small gears to produce a rotary motion. The grinding media (usually steel balls) in the drum are lifted up by the rotation of the drum, producing a certain motion trajectory.

1. Impact grinding: When the grinding media is lifted to a certain height, it will fall freely due to gravity, and produce an impact on the material at the bottom of the drum, thereby achieving the initial crushing of the material.

2. Friction grinding: During the rotation of the drum, friction and collision will occur between the grinding media and the material, and between the grinding media, and this friction and collision will further refine the material.

| Model | Cylinder Rotating Speed (r/min) |

Ball weight (t) |

Feeding Size (mm) |

Discharging Size (mm) |

Capacity (t/h) |

Power (kw) |

Total Weight(t) |

| Ф900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 95-110 | 630 | 149 |

| Ф3600×4500 | 17 | 90 | ≤25 | 0.074-0.4 | 115-170 | 850 | 169 |

| Ф3600x6000 | 17 | 110 | ≤25 | 0.074-0.4 | 120-200 | 1250 | 198 |

| Ф3600x8500 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000x5000 | 16.9 | 121 | ≤25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000x6000 | 16.9 | 146 | ≤25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | ≤25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | ≤25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | ≤25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | ≤25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | ≤25 | 0.074-0.4 | 148-615 | 4500 | 525 |

Problem manifestations: obvious vibration or abnormal noise during operation, which may be accompanied by gear wear, loose anchor bolts or bearing damage.

• Gear meshing problem: friction caused by gear tooth profile error, non-concentric installation, or insufficient lubrication.

• Loose anchor bolts: long-term fatigue or improper maintenance causes bolt breakage or loosening.

• Bearing damage: poor lubrication, assembly error, or impurities entering the bearing gap.

Check and adjust the gear meshing clearance and strengthen lubrication (such as using special grease).

Tighten or replace anchor bolts regularly, and match the equipment load when selecting materials.

Use special disassembly and assembly tools when replacing bearings, and ensure that the bearing temperature is below 120℃.

Problem manifestations: The life of the liner is significantly shortened, and even plastic deformation or fracture occurs.

• Material mismatch: The hardness difference between the liner and the grinding medium is too large (such as a high manganese steel liner with high chromium steel balls).

• Abnormal operation: The steel balls directly impact the liner under low load conditions, or the wet grinding environment accelerates corrosion.

• Choose a liner material that matches the hardness of the grinding medium (such as high chromium cast iron liner with high chromium steel balls).

• Maintain normal ore feed, avoid idling or low-load operation, and regularly clean up corrosive substances in the slurry.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery