The mobile hammer crusher has significant advantages in mobility, crushing efficiency, energy saving and environmental protection, easy operation, and adaptability. It is an ideal crushing equipment and is widely used in mining, construction, highways, railways, and other fields.

Mobile hammer crusher station is a kind of mobile crushing equipment with integrated feeding, crushing, screening, and conveying functions. The core adopts a hammer crusher, which crushes materials by a high-speed rotating hammer head. It is suitable for medium and low hardness stone (such as limestone, coal gangue, construction waste, etc.), and can be quickly transferred to reduce transportation costs.

• Medium and low hardness materials: compressive strength ≤ 200MPa, such as limestone, gypsum, coal, shale.

• Brittle materials: fragile and low moisture content (such as concrete and bricks in construction waste).

• Non-abrasive materials: avoid high silica (such as granite) to accelerate hammer wear.

Mobile Concrete Crusher

Mobile Hammer Crusher

Vibrating Screen

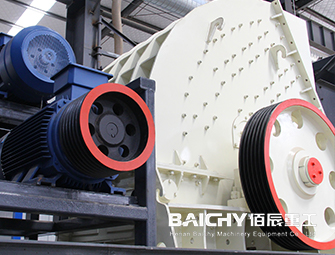

Heavy Hammer Crusher

Working principle of hammer crusher

| Item | M3S1848PCZ1308 | M3S1860 PCZ1510 | M3S1860 PCZ1512 |

| Transportation Length(mm) | 14000 | 16000 | 16000 |

| Transportation Width(mm) | 3100 | 3100 | 3100 |

| Transportation Height(mm) | 4300 | 4500 | 4500 |

| Maximum Length(mm) | 14000 | 16400 | 16400 |

| Maximum Width(mm) | 3400 | 3400 | 3400 |

| Maximum Height(mm) | 4700 | 4700 | 4700 |

| Weight(ton) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dual-axial | Dual-axial | Tri-axial |

| Crusher | PCZ1308 | PCZ1510 | PCZ1512 |

| Belt Converyor under Vibrating Screen | B800×7M | B800×8M | B800×8M |

| Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS1860 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery