Shale is a sedimentary rock with small grains. It's made when silt and tiny clay minerals, also called mud, are compressed together. It's special because it has layers that can be split into thin pieces easily. To get things like shale oil, gas, and other products, it's important to crush and grind the shale. This process has several steps, and each step needs a specific kind of machine to make the shale smaller and ready for the next step. Calcareous Shale Carbonaceous Shale Sandy Shale Siliceous Shale Shale Powder

Machines that crush and grind shale are used to reduce its size and prepare it for further processing. There are different types of shale grinding equipment to match different grinding particle sizes and outputs to meet the application of shale coarse and fine powder in industries.

Shale Raymond Mill ranges from 613 microns to 440 microns (0.613 mm to 0.44 mm), and the screening efficiency is 99%. the materials are ground between the grinding roller and the grinding ring. The fine powder that meets the fineness requirements is separated and collected.

Raymond Mill is widely used in the grinding and processing of mineral materials in the fields of metallurgy, building materials, chemical industry, and mining. It is suitable for processing materials with a Mohs hardness below level seven.

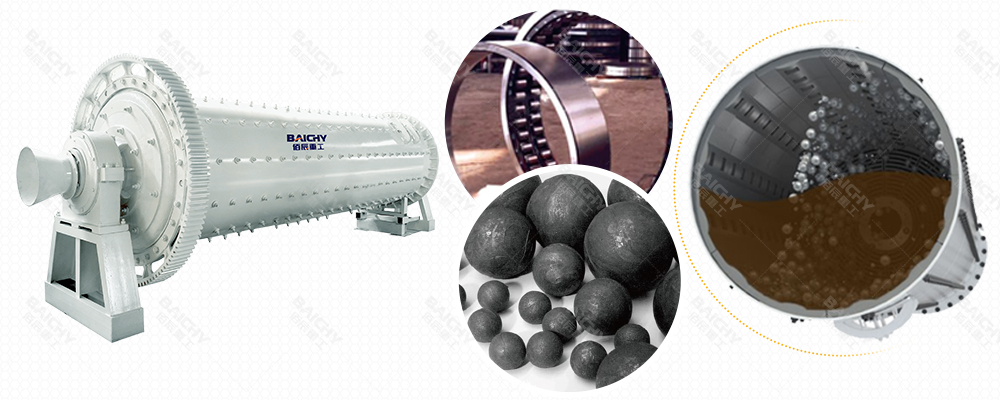

Shale Ball Mill containing steel balls as grinding media. The cylinder rotates, generating centrifugal force, lifting the steel balls to a certain height and then dropping them, which has a strong impact and grinding effect on the shale, producing powder.

Ball mills can be used for dry or wet grinding of various ores and other grindable materials. It has stable operation, reliable operation, large production capacity

The Shale Coarse Powder Mill is used for the preliminary grinding of shale. Shale is ground into the required powder size under the action of grinding rollers and grinding rings. The coarse shale powder is used in different industrial productions.

The MTW series European grinding mill can process various non-flammable and non-explosive mineral materials with a Mohs hardness below 9 and humidity below 6%.

Shale Ultrafine Grinding Mill is mainly used in industries that have high requirements on shale powder particle size. The material is ground into shale powder under the action of roller pressure.

The HGM micro-powder grinding mill can process ultra-fine powder of materials with Mohs hardness < 9.3 such as limestone, calcite, dolomite, talc, feldspar, coal gangue, ceramics, and coal. The fineness of the finished powder ranges between 150-2500 mesh.

Shale Vertical Grinding Mill can be used for shale grinding production, with the characteristics of uniform finished product particle size and large output. The material is ground into shale powder under the action of roller pressure.

A Vertical Roller Mill integrates crushing, drying, grinding, and grading into one machine, ensuring high production efficiency. Vertical Roller Mills are widely used in metallurgy, building materials, chemical industries, mining, and other fields.

● Strong grinding capacity

The shale crusher adopts advanced crushing technology and an efficient grinding mechanism, which can achieve efficient crushing and fine grinding of shale with high hardness and strong toughness, as well as other complex geological materials, greatly improving production efficiency.

● Stable grinding performance

The shale crusher adopts precise manufacturing technology and high-quality wear-resistant materials, ensuring equipment maintains stable grinding performance during long-term operation. At the same time, we are equipped with an intelligent control system to monitor the operating status of the equipment in real time. Once an abnormality is detected, it will automatically adjust to ensure the continuous and efficient operation of the equipment.

● Low grinding operation cost

The shale crusher adopts an energy-saving design, effectively reducing energy consumption. The equipment has a long service life and simple and convenient maintenance, reducing maintenance costs and downtime, and saving equipment replacement costs for enterprises.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!