Gold deposits can be divided into two categories: primary and secondary.

▶ Primary gold deposits form in bedrock and must be recovered through hard rock mining.These primarily include vein gold deposits (gold contained in quartz veins and possessing high grade), disseminated gold deposits (gold particles dispersed throughout the rock, large in size but low in grade), and refractory gold deposits (gold encapsulated in sulfides, requiring pretreatment for recovery).

▶ Secondary gold deposits, such as alluvial placer gold deposits (occurring in modern riverbeds) and ancient placer gold deposits (e.g., ancient conglomerate gold deposits in South Africa), are shallow and low-cost to mine. Gold particles can often be directly recovered through physical methods such as panning.

Primary ore mining and processing are technically complex and costly, especially for refractory gold ores, which require processes such as roasting or oxidation. Secondary ore, on the other hand, requires no crushing or grinding, making it a more primitive but still economically viable mining method.

The processing of gold ore is a complex and highly technical process. Its core goal is to maximize the separation and purification of gold from the ore, ultimately yielding high-purity gold (usually in the form of gold ingots).

The entire process can be broadly divided into four main stages: crushing and grinding, beneficiation (enrichment), smelting (purification), and refining.

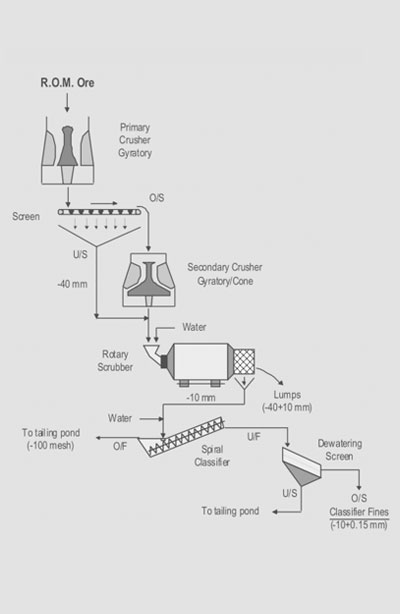

1. Primary Crushing: Using a jaw crusher or gyratory crusher, the ore is crushed to a size of approximately 100-150 mm in diameter.

2. Secondary Crushing: Using equipment such as a cone crusher, the crushed ore is further crushed to smaller sizes.

3. Tertiary Crushing and Grinding:

• Tertiary Crushing: A cone crusher may be used again.

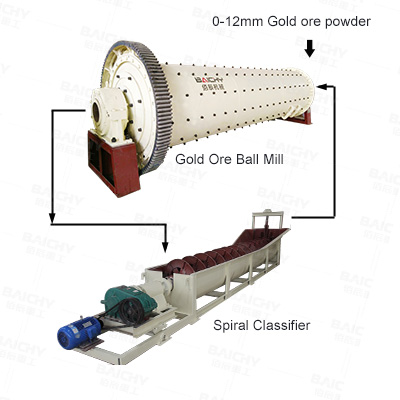

• Grinding: The crushed ore is fed into a ball mill or semi-autogenous grinding mill (SAG mill). Water and water-steel balls are added, and the ore is ground into a fine powder (usually as fine as flour or finer) through rotation. The resulting mixture is called a slurry.

• Role: Primary crushing (coarse crushing), the first stage of the entire crushing process.

• Main Function: Its primary task is to receive raw ore transported from the mine. This ore comes in a variety of sizes and shapes, with diameters up to 1 meter. The jaw crusher uses powerful mechanical force to crush it into fragments of approximately 100–250 mm, providing suitable feed for subsequent secondary and fine crushing.

Its operating principle simulates the chewing motion of an animal:

• The fixed jaw plate is fixed to the frame, acting as a reference surface.

• The movable jaw plate, driven by an eccentric shaft, performs periodic elliptical motion, sometimes approaching and sometimes moving away from the fixed jaw plate.

• When the two jaw plates approach, the ore in the crushing chamber is subjected to intense compression, splitting, and bending, resulting in crushing. When the movable jaw plate moves away, the crushed material is discharged from the discharge port under the action of gravity.

The jaw crusher is an essential primary crushing equipment for almost all mines and crushing plants. Its advantage lies in its ability to efficiently complete the challenging task of breaking down oversized ore into smaller pieces with low initial investment and operating costs, laying the foundation for stable operation of the subsequent process chain. While its product may have a poor particle size and shape, this is not its design focus; its core value lies in its stable, reliable, and efficient primary crushing.

• Role: Provides secondary and tertiary crushing. Typically located after the jaw crusher, performing the secondary or tertiary crushing stage. • Main Function: Further crushes coarse materials removed from jaw crushing, processing them into smaller particles (typically smaller than 10-50 mm).

• Working Principle: Its primary task is to receive feed material from the primary crushing process (typically 100-250mm) and process it into finer, more uniform particles through efficient crushing. Depending on the crushing chamber type and equipment configuration, the final product particle size can typically be controlled between 10-50mm, or even finer, providing an ideal feed for subsequent grinding processes.

The cone crusher's operating principle is based on laminated crushing:

• Crushing Structure: The device consists of a movable cone and a fixed cone, forming an annular crushing chamber between them.

• Crushing Action: Driven by an eccentric sleeve, the moving cone performs an oscillating motion, periodically approaching and moving away from the fixed cone.

• Crushing Mechanism: When the moving cone approaches, the material is subjected to intense squeezing, impact, and bending, resulting in crushing. When the moving cone moves away, the crushed material is discharged downward under the action of gravity, achieving continuous operation.

• Particle Size Adjustment: By precisely adjusting the cone's height through hydraulic or mechanical means, the discharge opening size can be varied, enabling precise and flexible control of the discharge particle size.

• Role: Screening and grading. It is typically used in conjunction with a crusher to form a "closed-loop" system.

• Pre-screening: Before entering the crusher, it removes fine materials that meet the requirements, preventing over-crushing and improving crushing efficiency. • Inspection and Screening: The material exiting the crusher is screened.

• Oversize (particle size larger than required): Returned to the preceding crusher (usually a cone crusher) for further crushing.

• Undersize (particle size meeting requirements): Qualified product is sent to the next process (usually a grinding plant).

• Working Principle: High-frequency vibrations generated by a vibrating motor cause the material to bounce across the screen surface, screening out particles smaller than the mesh size.

• Features: Implements a closed-loop crushing cycle, ensuring the final product's particle size strictly meets requirements, acting as a "quality inspector" for final product particle size control.

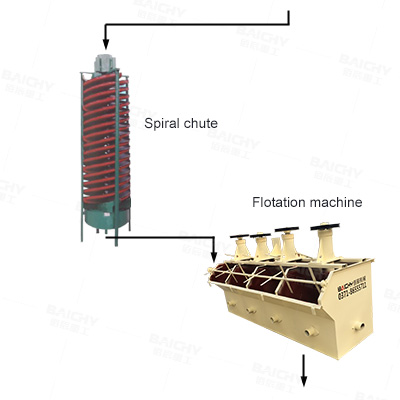

The ore pulp after grinding enters this stage, where gold is separated from other minerals through physical or chemical methods to obtain a high-grade gold concentrate or is directly output as gold.

The ore pulp after grinding enters this stage, where gold is separated from other minerals through physical or chemical methods, resulting in high-grade gold concentrate or direct gold production.

Depending on the distribution of gold in the ore (primarily particle size and its association with other minerals), two main process routes are used:

1. Gravity separation: Taking advantage of the fact that gold has a much higher density than gangue, a portion of coarse gold particles is recovered during or after the grinding process using shaking tables, spiral concentrators, or centrifugal concentrators. This gold can sometimes be directly smelted and is referred to as "gravity-concentrated gold." Cyanidation:

2. Leaching: The remaining ore pulp after gravity separation is fed into a series of large, agitated tanks (leaching tanks). A dilute sodium cyanide (NaCN) solution and air are added. The cyanide reacts chemically with the gold to form a soluble gold-cyanide complex, dissolving the gold from the solid ore into the solution.

4Au + 8NaCN + O₂ + 2H₂O → 4Na[Au(CN)₂] + 4NaOH

• Carbon in Pulp (CIP): Activated carbon is added to the leaching tanks, which adsorbs the gold-cyanide complex dissolved in the solution.

• Carbon in Leach (CIL): This process combines the leaching and adsorption processes in the same tank series, achieving higher efficiency and becoming the current mainstream process.

• Elution: The activated carbon loaded with gold complexes is separated from the ore pulp and fed into a high-temperature, high-pressure elution column. A special solution is used to "elute" the gold from the activated carbon, producing a highly concentrated precious solution.

• Electrowinning: The precious solution is fed into an electrolytic cell and fed with direct current. The gold in the solution is electrochemically reduced and deposited on the cathode, forming a gold sludge (mud). The activated carbon is then regenerated and recycled.

Have Any Questions!

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!