Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

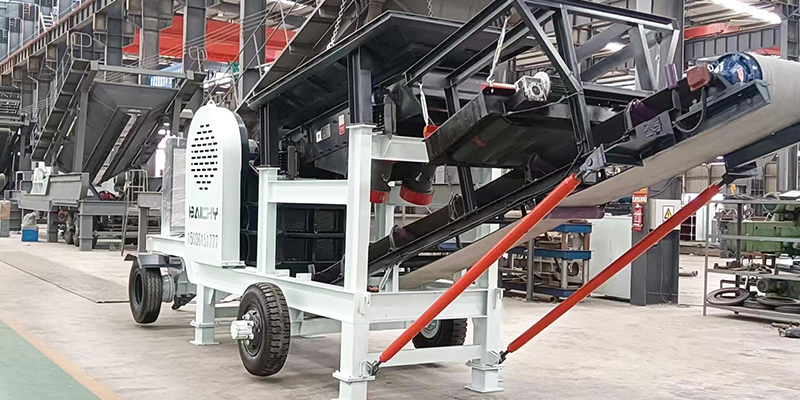

The small and simple mobile crusher can be put into production quickly at the sand and gravel aggregate crushing site. The equipment adopts a modular assembly structure. After arriving at the site, it only needs to connect to the power supply or refuel to start production. It takes only 4 hours from unloading to discharging.

The oil-electric dual-power design enables the equipment to operate immediately in remote mining areas without power grids, truly realizing the excellent performance of "production on site", helping customers seize the market opportunity.

✔ Ready to use, quick production in 1 hour

✔ Floor area <100㎡, suitable for various small sites

✔ Daily processing capacity of 50-300 t/d, meeting the needs of small and medium-sized sand and gravel plants

✔ Oil-electric dual power, can work without electricity in remote areas

✔ Integrated design, no need to disassemble for transfer and transportation

Intelligent crushing system designed for small sand and gravel aggregate plants

Specially optimized for small and medium-sized sand and gravel plants, construction waste recycling stations, road construction and other scenarios:

• Modular design: integrated feeding, crushing and screening

• Flexible configuration: optional jaw crusher, impact crusher, cone crusher and other crushing hosts

• Intelligent control: PLC automatic control system, 1 person can operate

• Environmental protection standard: equipped with pulse dust removal and noise reduction device

| Capacity(t/h) | 30-60t/h |

|---|---|

| Vibrating feeder | ZSW6520 |

| Size of Feed Spout(mm) | 650X2500 |

| Max Feeding size(mm) | 560 |

| Motor Power(kw) | 2X1.1 |

| Jaw Crusher | PE400x600 |

| Feed opening(mm) | 400x600 |

| Max. Feed Size (mm) | 350 |

| Discharging hole setting range(mm) | 40-90 |

| Motor Power(kw) | 30 |

| Belt conveyor | B500 |

| Width(mm) | 500 |

| Length(mm) | 6000 |

| Motor Power(kw) | 4KW |

| Power system | Electrical Control or Generator Set according to Jobsite |

| Chassis | 2 bridge + hand-operated jack system |

The standard capacity is 30-60 t/h, and the specific output depends on the hardness of the material (e.g., about 40 t/h for granite and up to 60 t/h for limestone) and the discharge size adjustment (adjustable from 40-100 mm).

The maximum feed size is ≤340 mm, suitable for crushing medium-hard rocks (compressive strength ≤320 MPa), concrete blocks, construction waste, etc.

• No fixed foundation required: tire or crawler movement, fast transfer, saving installation time and cost.

• Adapt to decentralized operations: especially suitable for short-term projects such as building demolition, temporary mines, road maintenance, etc.

• Integrated design: the main machine, feeder, and belt conveyor are integrated into one, and can work by plugging in.

• Standard motor drive (power of about 30- 45 kW), more energy-efficient than diesel units, requires a 380V industrial power supply.

• If there is no power supply, a diesel generator can be selected, but the cost will increase.

• Applicable: granite, limestone, concrete blocks, bricks and tiles, and other construction waste.

• Not applicable: Concrete containing a large amount of steel bars (the steel bars must be removed first), or high-hardness ores (such as quartzite).

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!