Coal is a solid fossil fuel formed from ancient plant remains through long periods of geological action underground. It has abundant and concentrated reserves worldwide. It can be divided into anthracite, bituminous coal, and lignite, depending on its degree of carbonization. Its primary uses are in power generation and metallurgy, but it is also a vital chemical raw material.

Regarded as the "food of industry," coal, with its vast reserves, low price, and stable supply, has long been the cornerstone of the global energy system, providing crucial support for industrialization and power generation in many countries. However, its mining and combustion also lead to severe environmental pollution, ecological damage, and greenhouse gas emissions, placing it under immense environmental pressure.

Amid the global energy transition, coal's future development is trending toward clean and efficient utilization, with carbon capture technologies reducing emissions. Its role is gradually shifting from a simple fuel to a chemical raw material. Despite this, it remains a crucial component of the current energy mix, but its long-standing dominance is being increasingly challenged by renewable energy.

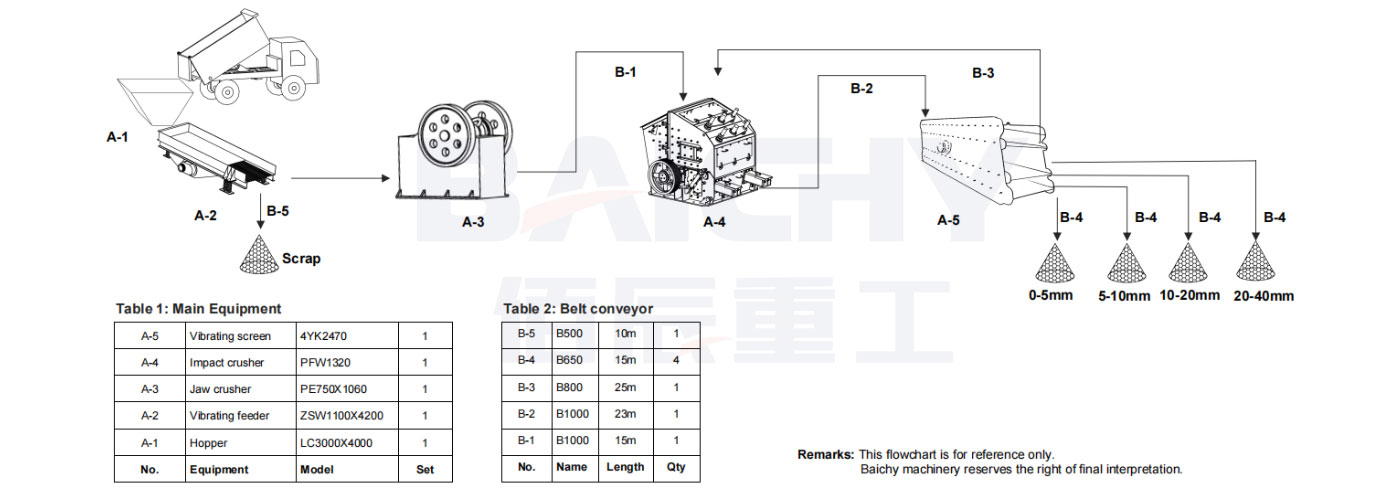

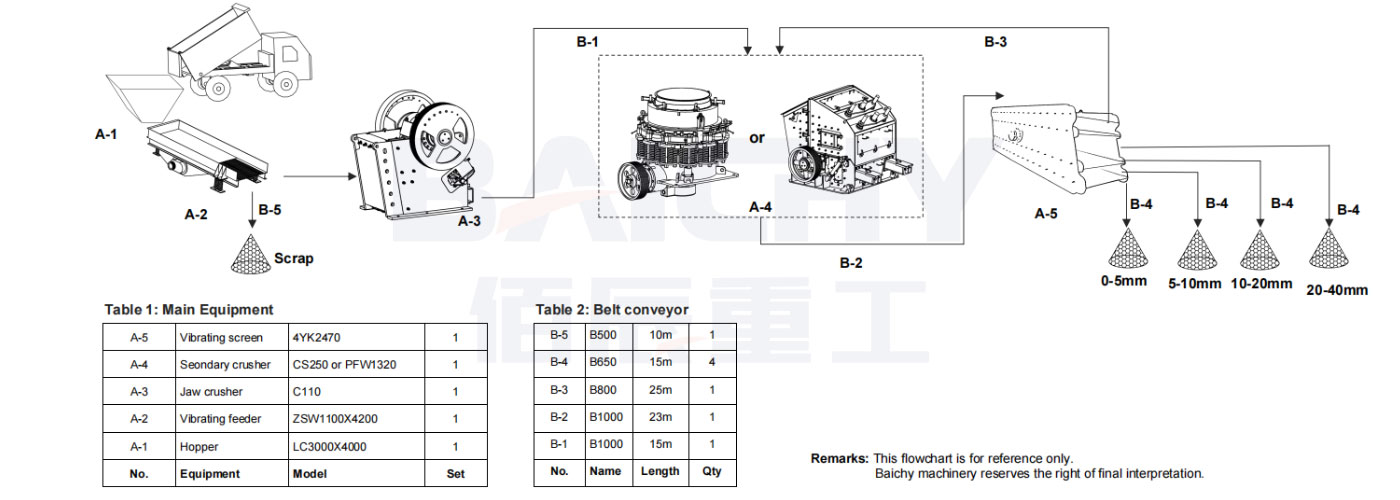

▶ Coal crushing is the first and most crucial step in coal utilization (power generation, coking, and gasification). Improperly selected crushing equipment can lead to low production efficiency, high energy consumption, soaring maintenance costs, and even compromised final product quality.

▶ With so many different coal crushers on the market, how can you make an informed choice? This article will provide an in-depth and easy-to-understand introduction to the types and operating principles of mainstream coal crushers, along with a practical selection methodology.

▶ After reading this article, you'll clearly understand which crusher best suits your specific needs.

1. Why is crushing necessary? Briefly describe the purpose of coal crushing: meeting transport size requirements, improving combustion efficiency, and facilitating subsequent processing (such as washing and coking).

2. Applications: Thermal power plants, coking plants, coal chemical industry, building materials industry (cement production), and coal storage and transportation centers.

• Working Principle: "Tiger mouth" type crushing, involving periodic squeezing between the movable and stationary jaws.

• Features: Simple structure, durable, high processing capacity, suitable for primary coarse crushing.

• Advantages: Large feed size, high crushing ratio, and easy maintenance.

• Disadvantages: Uneven product size, frequent flaky products, and high noise and vibration.

• Applicable to: The first crushing step for large raw coal.

• Working Principle: The hammer strikes the material, causing it to strike the impact plate for repeated crushing.

• Features: Combines impact and grinding action, with strong selective crushing capability.

• Advantages: High energy efficiency, good product shape, and low dust.

• Disadvantages: The hammer and impact plate are easily worn, making it unsuitable for crushing very hard materials.

• Applicable to: Medium and fine crushing, especially where product shape is of particular importance.

• Working Principle: High-speed rotating hammers impact, shear, and grind the material.

• Features: Single-stage crushing, no secondary crushing required, and easy particle size adjustment.

• Advantages: High crushing ratio, high production efficiency, and fine product size (high cubic content).

• Disadvantages: Rapid hammer wear, unsuitable for materials with high hardness or high moisture content.

• Applications: Medium and fine crushing of medium-hard coal requiring uniform product size.

• Main Unit: Heavy-duty Hammer Crusher

• Features: Integrated design, self-propelled travel, and rapid deployment

• Advantages: Extremely high maneuverability and flexibility, integrated unit, and space-saving

• Disadvantages: High investment cost per unit, limited processing capacity

• Applications: Coal seam mining after overburden stripping in small and medium-sized open-pit coal mines

The core is a high-speed rotating rotor with multiple heavy hammers hingedly attached. After entering the crushing chamber, the material is crushed by the impact and collision of the high-speed hammers, as well as by collisions with the inner lining of the crusher. Qualified particles are discharged through the gaps between the bottom grate bars, thus controlling the output particle size.

• Features: "One-shot crushing" design, high crushing ratio, and no secondary crushing required.

• Advantages: The finished particles are mostly cubic and uniform in size.

• Disadvantages: >When crushing high-hardness materials or coal with high impurities, wearing parts such as hammers and liners are high in consumption and require frequent replacement, resulting in high operating costs.

• Applications: Middle and fine crushing of medium-hardness coal (such as bituminous coal and lignite).

It consists of two rollers rotating in opposite directions. Material falls between the rollers by gravity or a feeder, where it is continuously squeezed and ground, crushing it. The output particle size is determined by the gap between the rollers.

• Features: Extremely low over-crushing rate, effectively preserving the original particle size of the material.

• Advantages: The maximum output particle size can be precisely controlled by simply adjusting the roller gap.

• Applications: Fine and ultra-fine coal crushing, particularly for briquette and pulverized coal preparation.

The material is crushed using the periodic compression and release between the "moving jaw" and "fixed jaw." The dynamic plate simulates the movement of an animal's jaws, squeezing and breaking the material entering the crushing chamber to achieve the desired crushing effect.

• Features: Large feed opening, capable of handling large lumps of material.

• Advantages: Simple structure, sturdy components, low failure rate, and capable of processing hard coal mixed with gangue.

• Disadvantages: The finished product contains a high concentration of flaky material, and the particle size adjustment range is limited.

• Applications: Preliminary crushing in small and medium-sized coal mines, coal washeries, and laboratories; processing raw coal containing a high concentration of gangue and other impurities.

This unit is essentially a small jaw crusher, integrated with the feeder, motor, steel frame, and discharge conveyor on a single, integrated framework.

• Features: This semi-mobile solution offers more flexibility than fixed installations, but not as flexible as tire/crawler mobile crushers.

• Advantages: Once delivered to site, production can begin with simple site leveling and power connection, significantly shortening the construction cycle.

• Disadvantages: Typically only features primary crushing, and its functional scalability is inferior to that of modular mobile crushers.

• Applications: Quarries and small coal mines require phased, decentralized operations.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!