Crushing Equipment

①Jaw Crusher: PE250x400 Jaw Crusher (the lowest price)

PE250x400 Jaw Crusher is used for coarse crushing (primary crushing) of rock materials with any hardness.

The most important parts are jaw plates made of high-manganese steel.

Maximum feed size: 0-210 mm

Capacity: 5-20 t/h

②Hammer Crusher: PC400X300 Hammer Crusher (the lowest price)

PC400X300 Hammer Crusher is used for medium and fine crushing of medium-hard and brittle materials.

One-time crushing without secondary crushing and shaping process. The output size is small, uniform, and cubic with less over-crushing.

Maximum feed size: 0-100 mm

Capacity: 5-10 t/h

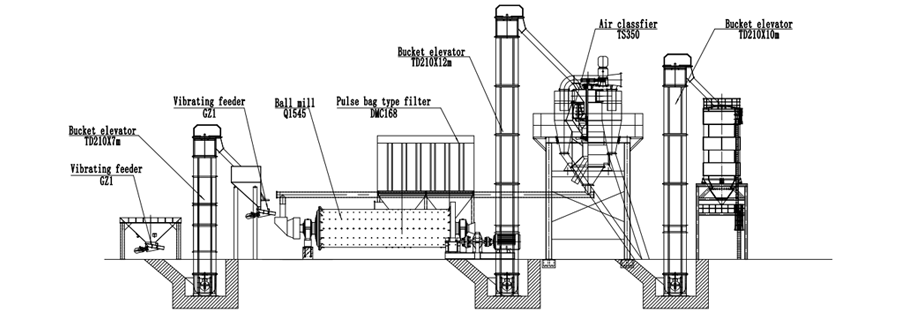

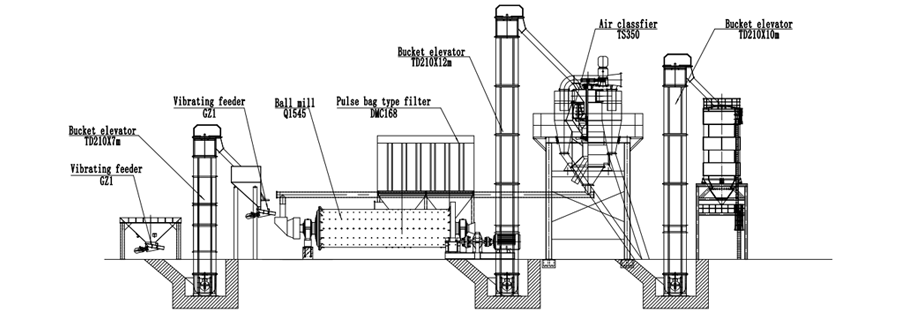

Mill Equipment - Ball mill

Ball mills are widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizers, ferrous and non-ferrous metal beneficiation, and glass ceramics, etc., for dry or wet grinding of various ores and other grindable materials.

Ball mill in cement grinding

The main purpose of the cement ball mills is to grind the clinker and gypsum into a finer powder to produce the final cement product.

In addition to grinding clinker and gypsum, ball mills can also be used for grinding other materials such as slag, pozzolan, dolomite, and fly ash. These materials are added to the cement to improve its properties, such as strength and durability.

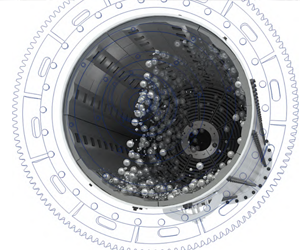

In the operation of the ball mill, the grinding of the material is mainly completed through the grinding body.

Ball mill grinding body - Steel ball

Steel ball is a kind of grinding body commonly used in ball mills. Ball mill manufacturers often choose steel balls of various specifications with a diameter of 20-120mm according to the grinding process requirements of the material; for the coarse grinding chamber of the ball mill, various steel balls with a diameter of 50-100mm are generally selected, and the fine grinding chamber is selected for a diameter of 20-100mm. 50mm various steel balls.

How does a ball mill work?

The material is initially crushed by the jaw crusher, and the crushed material is screened by the vibrating screen, and the material that meets the particle size requirements is evenly sent to the ball mill by the feeder, and the ore is crushed and ground by the ball mill. The material enters the first chamber of the mill evenly and spirally through the feeding hollow shaft from the feeding device of the ball mill. There are stepped lining boards or corrugated lining boards in the chamber, and steel balls of different specifications are installed inside. The rotation of the cylinder produces centrifugal force to bring the steel balls to a certain level. After falling from a high height, it will impact and grind the material. Materials get coarse-grind in the first warehouse, then into the second warehouse through the single compartment. The second warehouse has a flat liner and is also filled with balls, then grind the material again. The powder is discharged through the unloading grate plate to complete the grinding operation.

What is the main function of the ball mill:

- 1. Grinding refinement: The ball mill can grind materials with a low hardness to gradually refine them, increasing the surface area, and thereby changing its physical and chemical properties, such as increasing the reaction rate and reducing the burning point.

- 2. Uniform mixing: the ball mill can mix a variety of different materials together to achieve a uniform mixing effect, which is used to prepare alloys, composite materials, pigments, biological products, etc.

- 3. Dispersion and polishing: the ball mill can disperse pigments, paints, and other materials evenly to achieve the effect of polishing and make the color more vivid and uniform.

- 4. Reach the target particle size: The ball mill can grind the raw material into particles of a specific particle size according to the requirements to meet the needs of specific processes and applications.