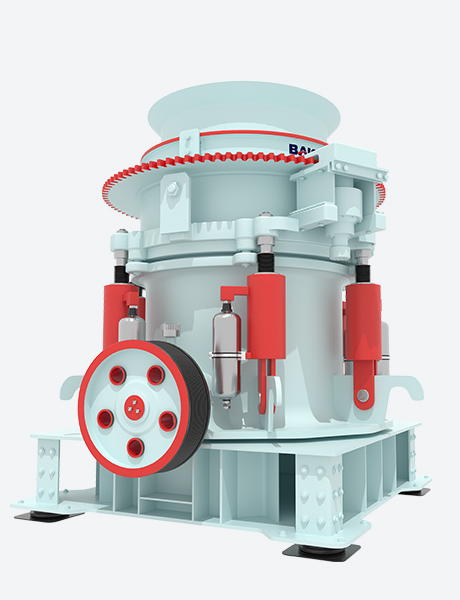

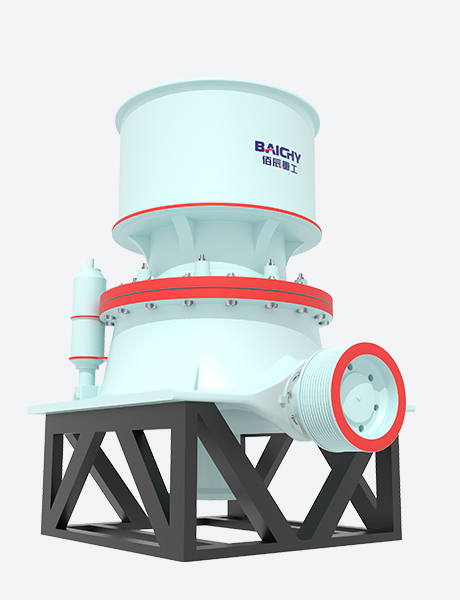

Multi-cylinder hydraulic cone crusher is a typical medium and fine crushing equipment for hard materials. It is developed on the basis of a spring cone crusher. Its basic structure is similar to that of a spring cone crusher, but it has more functions and advantages.

Suitable for crushing various mining rocks, such as iron ore, non-ferrous metal ore, basalt, granite, limestone, sandstone, pebbles, etc.

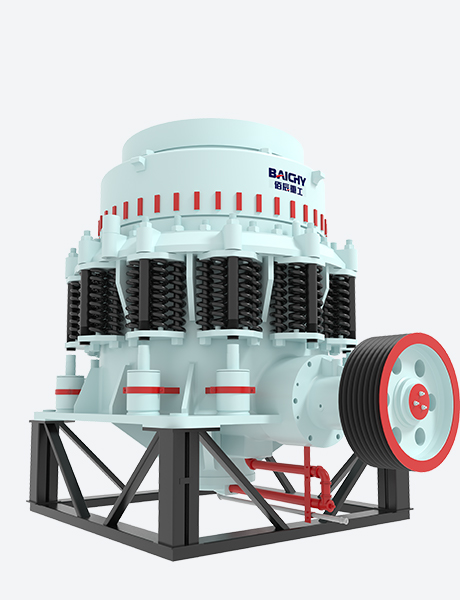

Symons cone crusher is a modern high-performance crusher designed and developed based on the introduction and absorption of foreign technology, combined with customer needs, and based on the principle of laminated crushing and the concept of more crushing and less grinding.

Symons cone crusher is widely used in metal and non-metallic mines, cement plants, construction, sand and stone metallurgy, and other industries, such as the crushing of iron ore, non-ferrous metal ore, granite, limestone, quartzite, sandstone, pebbles, etc.

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

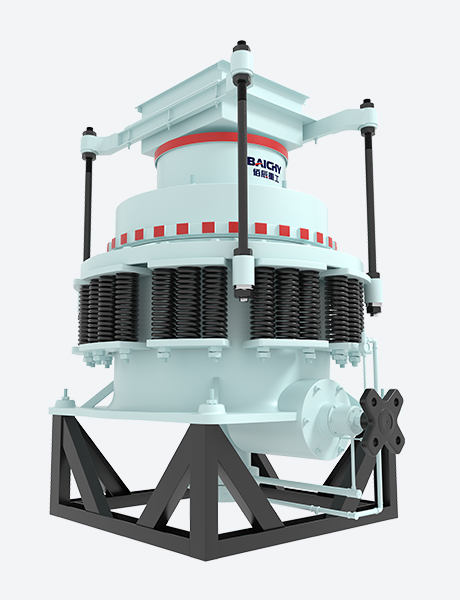

The eccentric sleeve is driven by the motor to rotate, driving the moving cone to swing periodically, and the material is crushed by squeezing, impacting, and bending between the moving cone and the fixed cone. The crushed material is discharged from the bottom discharge port.

• Spring cone crusher: Overload protection through spring, low cost, suitable for medium-hard materials.

• Hydraulic cone crusher (single cylinder/multi-cylinder): Hydraulic adjustment of discharge port and overload protection, high degree of automation, suitable for high-hardness materials (such as granite, basalt).

• Compound cone crusher: Combining spring and hydraulic technology to balance performance and price.

• Material hardness: Choose the hydraulic type for high hardness, and spring type for medium and low hardness.

• Capacity demand: Choose a multi-cylinder hydraulic cone crusher for large production lines (with an output of more than 1,000 tons per hour).

• Finished product size: Short head type for fine crushing and standard type for medium crushing.

• Budget: The price of the hydraulic type is higher than that of the spring type, but the maintenance cost is lower.

Cause: Unstable foundation, uneven wear of liner, too much feed.

Solution: Strengthen foundation, replace liner, adjust feed amount.

Cause: Wear of the liner, insufficient pressure of the hydraulic system.

Solution: Check the liner and replace it, and adjust the hydraulic cylinder pressure.

Cause: Oil circuit blockage, cooler failure, or oil quality deterioration.

Solution: Clean the oil circuit, replace the cooler or hydraulic oil.

• Jaw crusher: The first choice for coarse crushing, with a simple structure, but with an uneven particle size of the finished product.

• Impact crusher: It is suitable for medium and fine crushing of low-hardness materials, and the finished product has a good particle shape (more cubes).

• Cone crusher: Medium and fine crushing of high hardness materials, low energy consumption, but complex maintenance, slightly higher powder content in the finished product.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!