Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The CS160 cone crusher is ideal for handling medium-hard and abrasive materials. Its robust structure and laminated crushing principle ensure high efficiency while effectively controlling wear on vulnerable parts.

The CS160 cone crusher is a classic medium-capacity secondary crushing machine with a wide range of applications. Its core value lies in further crushing coarse material (100-300mm) from primary crushing (such as jaw crushing) into the desired fine-grained small- to medium-sized aggregate (typically 3-60mm).

• Role: Serves as the main "secondary crushing" (secondary crushing) unit in the production line.

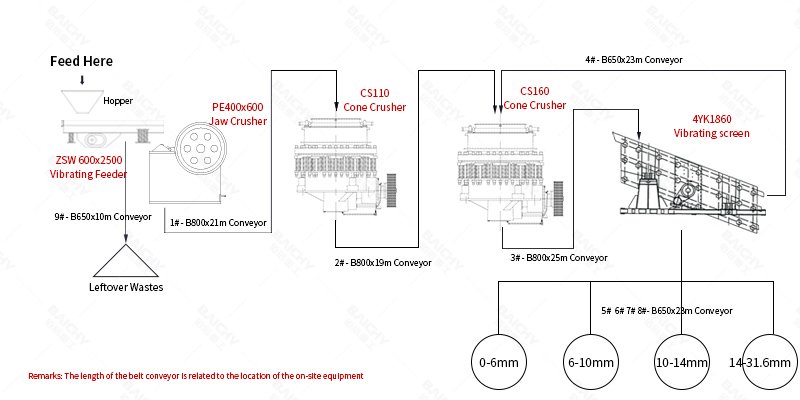

• Process: Vibrating feeder → Jaw crusher (primary crushing) → CS160 cone crusher (secondary crushing) → Vibrating screen (classification) → Finished aggregate or feeds the sand making machine.

Features: In this configuration, the CS160 consistently produces high-quality, cubic aggregate, a key factor in ensuring production line efficiency and final product quality.

• Role: Secondary crushing of mined ore to provide raw material of suitable particle size for subsequent grinding.

• Applicable Minerals: Metal ores such as iron ore, copper ore, gold ore, lead and zinc ore, and some non-metallic ores. By reducing particle size through crushing, grinding energy consumption can be significantly reduced, improving beneficiation efficiency.

• Role: Finely crushing pre-processed construction waste (e.g., removed rebar), such as concrete blocks and bricks and tiles.

• Value: The crushed recycled aggregate has a fine particle shape and can be used in the production of recycled bricks, road base layers, and other applications. The CS160's laminated crushing technology effectively reduces microcracks in the recycled aggregate.

| Model | CS160-C | CS160-M | CS160-F |

|---|---|---|---|

| Crushing Cone Dia.(mm) | 1295(4 1/4') | 1295(4 1/4') | 1295(4 1/4') |

| Adjusting Range of Discharge Opening(mm) | 19-51 | 16-38 | 13-31 |

| Max feeding size (mm) | 205 | 178 | 115 |

| Motor Power(kw) | 160 | 160 | 160 |

| Capacity(t/h) | 172-349 | 132-253 | 109-181 |

| Overall Dimension(mm) | 2983×1866×3156 | 2983×1866×3156 | 2983×1866×3156 |

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Vibrating Feeder | ZSW9638 | 1 |

| 2 | Jaw Crusher | PE600x900 | 1 |

| 3 | Cone Crusher | CS160 | 1 |

| 4 | Cone Crusher | CS160 | 1 |

| 5 | Vibrating Screen | 4YK1860 | 1 |

| 6 | Belt Conveyor | B800 | 3 |

| 6 | Belt conveyor | B650 | 6 |

In a modern crushing line, each piece of equipment functions like a precision gear, each performing its own function and working in unison. The CS160 cone crusher plays a crucial role: the core of efficient secondary crushing. It performs coarse crushing, laying the foundation for fine crushing or sand making, and is a key factor in determining final output and product quality.

Feeding → Primary Crushing (Coarse Crushing) → Secondary Crushing (Secondary Crushing) → Screening → (Tertiary Crushing/Sand Making) → Finished Product

Primary Crushing (Coarse Crushing): Typically performed by a jaw crusher, it reduces large raw materials (such as rough stone with a diameter of 500-1000mm) to approximately 100-300mm. It is characterized by its ability to "eat coarse grains" and handle large volumes.

Secondary Crushing (Secondary Crushing): This is where the CS160 cone crusher comes in. It refines the coarse grains from the jaw crusher, reducing them to an intermediate particle size of approximately 20-60mm. Screening and Closed Loop: After crushing, the material enters the vibrating screen, where qualified materials are screened out as finished products. Excessive materials are returned to the secondary crushing equipment for further crushing, forming a closed-loop system. This "return material," known as the "closed loop," is key to ensuring uniform particle size in the finished product.

Thus, the CS160's positioning is clear and crucial: it serves as a core bridge connecting the upper and lower levels.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!