Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

The CS110 Symons cone crusher, with its classic design, reliable performance, and proven technology, continues to hold a prominent position in medium-scale secondary and tertiary crushing operations.

The core of the CS110 cone crusher lies in its unique laminated crushing principle. Unlike the "single-point impact" of a jaw crusher, the cone crusher's movable cone rotates eccentrically within the fixed cone. Within the crushing chamber, the material is not only subjected to compression but also to bending and shear forces from the oscillating motion of the movable cone. This multi-directional force causes the material to be crushed multiple times within the crushing chamber, creating a "stone grinding stone" effect.

• High Efficiency and Energy Saving: More energy is used to crush the material rather than dissipate wear on metal components, thereby reducing energy consumption per unit of output.

• Excellent Particle Shape: The resulting finished material is mostly cubic, with a low content of flakes and a uniform particle size, making it ideal as an aggregate for high-grade concrete.

• Crushing high-hardness ores such as granite and basalt: It performs secondary or tertiary crushing in sand and gravel aggregate production lines.

• Crushing metal ores such as iron ore and copper ore: It provides raw materials of the required particle size for subsequent grinding and beneficiation processes.

• Construction waste recycling: It crushes discarded concrete blocks into recycled aggregate, achieving resource recycling.

| Model | CS110-C | CS110-M | CS110-F |

|---|---|---|---|

| Crushing Cone Dia.(mm) | 1200(4') | 1200(4') | 1200(4') |

| Adjusting Range of Discharge Opening(mm) | 19-50 | 13-38 | 9-31 |

| Max feeding size (mm) | 180 | 130 | 90 |

| Motor Power(kw) | 110 | 110 | 110 |

| Capacity(t/h) | 110-250 | 80-180 | 63-140 |

| Overall Dimension(mm) | 2821×1974×2651 | 2821×1974×2651 | 2821×1974×2651 |

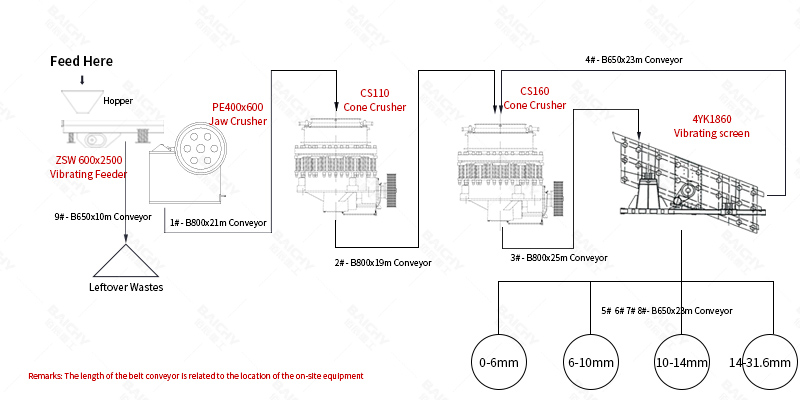

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Vibrating Feeder | ZSW9638 | 1 |

| 2 | Jaw Crusher | PE600x900 | 1 |

| 3 | Cone Crusher | CS110 | 1 |

| 4 | Cone Crusher | CS160 | 1 |

| 5 | Vibrating Screen | 4YK1860 | 1 |

| 6 | Belt Conveyor | B800 | 3 |

| 6 | Belt conveyor | B650 | 6 |

The CS110 Symons cone crusher is a standard model in the Symons series of cone crushers. It utilizes laminated crushing technology and is primarily used for secondary and tertiary crushing of ores and rocks of medium or higher hardness.

A typical crushing production line typically consists of primary crushing, secondary crushing, tertiary crushing, and screening. The CS110 Symons cone crusher's core function is secondary crushing (secondary crushing), and it may also perform tertiary crushing (tertiary crushing) depending on process requirements.

• Upstream: Typically connected to a jaw crusher for primary crushing. The jaw crusher is responsible for crushing large materials (such as large rocks) to a particle size of less than 250mm.

• Downstream: Connected to a vibrating screen, qualified material is screened and separated as finished product, while unqualified coarse material is returned or sent to the next stage, a tertiary cone crusher or sand making machine, for further processing. In this process, the CS110 further crushes the "semi-finished products" from the jaw crusher to a particle size more suitable for subsequent processing (usually between 20-40mm). Its stable performance and uniform discharge lay a solid foundation for subsequent processes.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!