Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In an increasingly competitive market, investing in technologically advanced and reliable equipment like the CH660 means lower overall operating costs, higher product added value, and significantly enhanced market competitiveness. It's not only a powerful and efficient tool for current production, but also a solid foundation for the long-term development of your business.

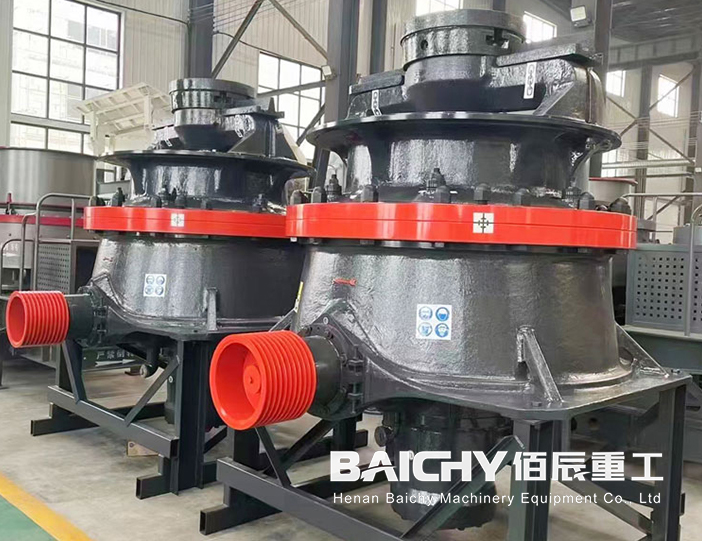

The CH660 is a powerful tool designed to tackle challenging challenges. It is particularly suitable for large, modern mines and gravel pits with stringent requirements for product quality and output, helping users maintain a leading position in the high-quality race.

Unlike traditional spring cone crushers or multi-cylinder hydraulic cone crushers, the CH660's single-cylinder design integrates the hydraulic cylinder at the bottom of the main shaft, serving as both a transmission component and a regulating and protective element.

• Crushing Function: The hydraulic system provides continuous and stable pressure, driving the main shaft and moving cone up and down, achieving continuous, layered crushing of the material.

• Discharge Opening Adjustment: By raising and lowering the moving cone assembly, the discharge opening can be precisely and quickly adjusted to control product particle size.

• Iron Overload Protection: When uncrushable material (such as iron) enters the crushing chamber, system pressure increases, causing the hydraulic cylinder to automatically release pressure, allowing the cone to drop and expel the foreign object. The hydraulic cylinder then automatically resets, protecting the core components of the equipment.

• Cavity Clearing: In the event of a material blockage, the hydraulic system can be operated to raise and lower the cone, quickly clearing the crushing chamber and resuming production.

| Model | Cavities | Feeding Size(mm) | Adjusting Range of Discharge Opening (mm) | Capacity(t/h) | Power(kw) |

|---|---|---|---|---|---|

|

CH660 (DG500) |

Extra Coarse - EC | 321 | 16-51 | 177-662 | 315 |

| Coarse - C | 253 | 16-51 | 171-643 | ||

| Medium Coarse - MC | 198 | 16-44 | 162-552 | ||

| Medium - MF | 155 | 16-38 | 197-502 | ||

| Medium Fine - MF | 133 | 13-38 | 192-451 | ||

| Fine - F | 96 | 13-38 | 195-4 |

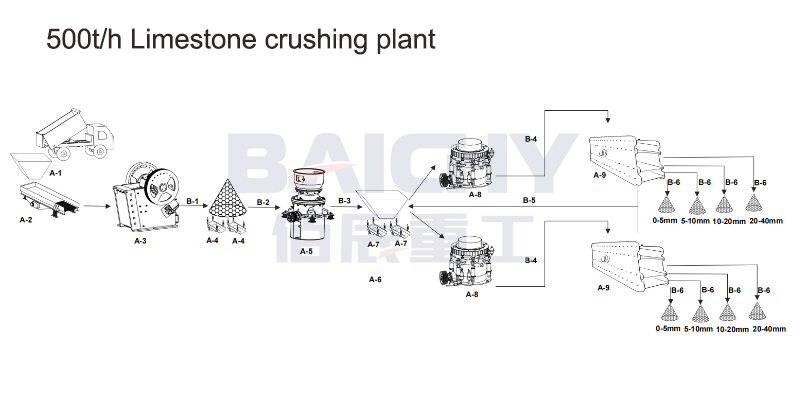

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating feeder | ZSW1349 | 1 |

| 3 | Jaw Crusher | C140 | 1 |

| 4 | Cone Crusher | HP300 | 1 |

| 5 | CH Cone Crusher | CH-660 | 1 |

| 6 | Vibrating Screen | 4YK2470 | 1 |

| 7 | Belt | B1000 | 8 |

In large-scale sand and gravel aggregate or metal mining production lines, secondary and tertiary crushing is crucial for determining final output, product quality, and operational profitability. Choosing a powerful core crushing equipment is crucial. Baichen Heavy Industry's CH660 single-cylinder hydraulic cone crusher is the "core engine" designed to meet the stringent requirements of large-scale production lines, ensuring efficient and stable operation of the entire system with its superior performance.

• High and Stable Processing Capacity: Continuous material feeding to downstream screening and conveying systems is essential to avoid becoming a production bottleneck.

• Extremely High Operational Reliability: Unplanned downtime can cause the entire line to shut down, resulting in significant losses.

• Controllable Product Shape: Producing aggregates with superior particle shape (more cubic, less flake) is key to increasing product added value.

• High Adaptability and Intelligence: The discharge opening can be quickly adjusted to accommodate market demand changes and includes intelligent protection features.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!