Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

In the fields of mining crushing, sand and gravel aggregate production, cone crushers have become core equipment due to their efficient and stable crushing performance. The PYB1750 spring cone crusher has become an ideal choice for crushing medium-hard ores (such as granite, basalt, and iron ore) with its unique spring safety device, high crushing ratio, and low energy consumption.

The PYB1750 adopts a spring overload protection system. When unbreakable objects (such as metal foreign objects) enter the crushing chamber, the spring will automatically compress, enlarge the discharge port to discharge foreign objects, and avoid equipment damage. Compared with hydraulic cone crushers, the spring structure is simpler and the maintenance cost is lower, which is particularly suitable for users with limited budgets but pursuing stability.

The equipment adopts "laminated crushing" (particles squeeze and crush each other) instead of single particle impact crushing, so that the finished aggregate particle shape is uniform and the needle-like content is low, which is particularly suitable for the production needs of high-grade sand and gravel aggregates (such as sand and gravel for highway and high-speed railway construction).

| Model | PYB-1750 | PYZ-1750 | PYD-1750 |

|---|---|---|---|

| Cone Dia.(mm) | 1750 | 1750 | 1750 |

| Max feeding size (mm) | 215 | 185 | 85 |

| Adjusting Range of Output Size(mm) | 25-60 | 10-30 | 5-15 |

| Capacity(t/h) | 280-480 | 115-320 | 75-230 |

| Motor Power(kw) | 160 | 160 | 160 |

| Overall Dimension(mm) | 4870×3800×4192 | 4870×3800×4192 | 4870×3800×4192 |

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

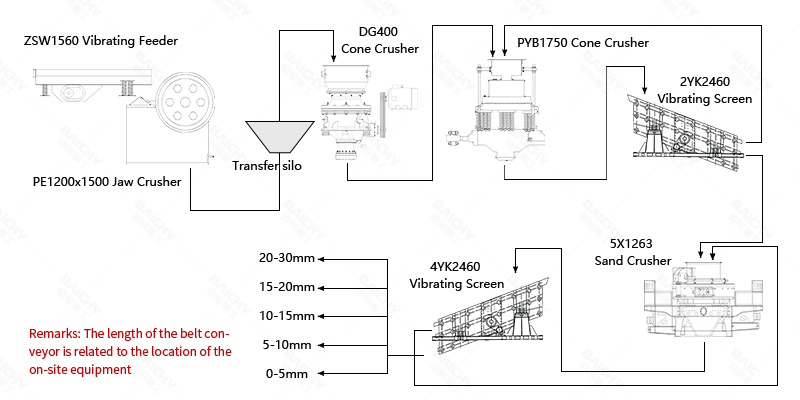

| 1 | Vibrating Feeder | ZSW1560 | 1 |

| 2 | Jaw Crusher | PE1200x1500 | 1 |

| 3 | Cone Crusher | DG400 | 1 |

| 4 | Cone Crusher | PYB1200 | 1 |

| 5 | Vibrating Screen | 2YK2160 | 1 |

| 6 | Vibrating Screen | 4YK2160 | 1 |

| 7 | Sand Making Machine | 5X1263 | 1 |

| 8 | Belt Conveyor | B1400 | 4 |

| 9 | Belt Conveyor | B1200 | 2 |

| 10 | Belt Conveyor | B800 | 11 |

| 11 | Belt Conveyor | B1000 | 1 |

1.1 Processing capacity matching:

• The maximum feed size of PYB1750 standard cone crusher is 215mm

• Theoretical processing capacity is 180-280 t/h (medium hard materials)

• Under actual working conditions, by adjusting the discharge port (adjustable 25-60mm), the 150-200t/h production capacity requirement can be stably achieved

1.2 Crushing ratio advantage:

• Standard crushing ratio 1:5-1:8

• Aggregates ≤200mm can be directly crushed to ≤50mm at one time

• Closed-loop circulation can be formed with a vibrating screen to reduce the need for secondary crushing

• Typical process flow: feeder (ZG1538) → jaw crusher (PE750×1060) → PYB1750 cone crusher → 3YK2460 vibrating screen → belt conveyor system

• Motor power: 160kW (meet heavy-load start requirements)

• Hydraulic system working pressure: ≤2MPa

• Lubrication system flow: 25L/min (double filter is recommended)

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!