Baichy Heavy Industrial Machinery Co., Ltd

Phone/Wechat/Whatsapp:+008615093222637

Email:[email protected]

24 hours online

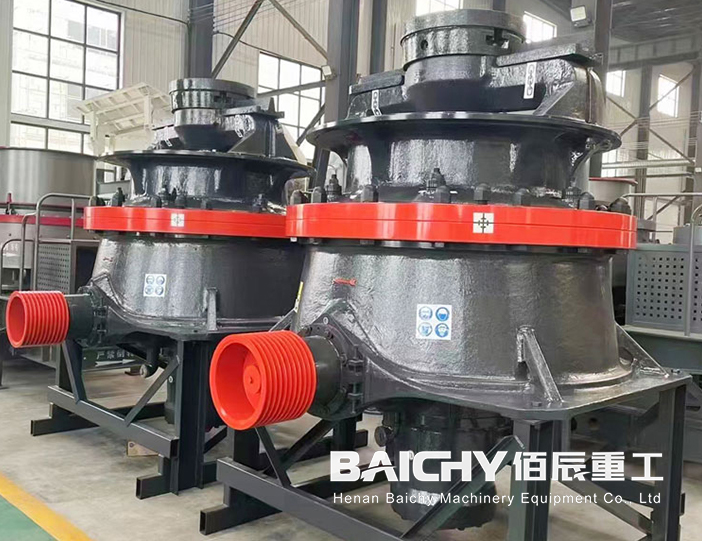

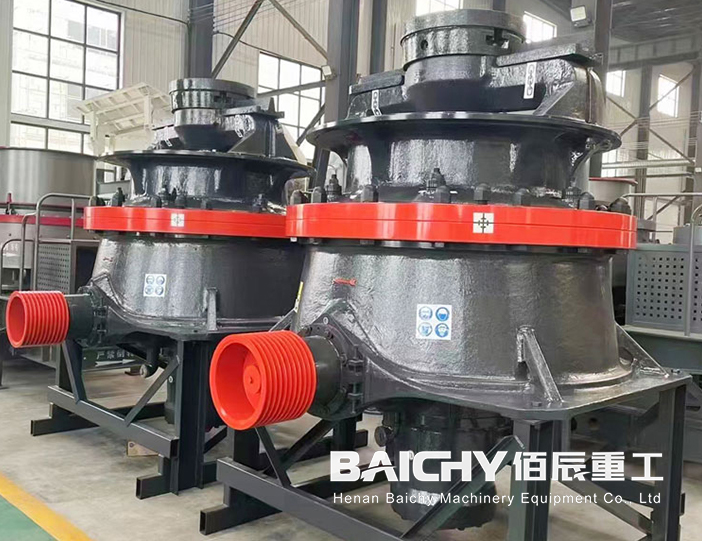

In modern sand and gravel production lines, the performance of secondary and tertiary crushing equipment directly impacts overall profitability. The CH-440 single-cylinder hydraulic cone crusher was designed precisely for this purpose. Combining the simplicity and reliability of single-cylinder hydraulic technology with an optimized design for medium-scale production, it is ideal for processing medium-to-high-hardness materials such as granite, basalt, and pebbles.

As the core secondary crushing equipment in medium- to large-scale production lines, the CH-440 meets the stringent requirements of most high-standard aggregate production processes.

Designed with the principle of "simple in form, powerful in spirit," the CH-440 creates tangible value for users in five key dimensions:

1. Powerful and Efficient:The optimized crushing chamber and eccentricity are specifically designed for medium-to-high-hardness materials, delivering powerful crushing force and stable and reliable output.

2. Excellent Particle Shape:Utilizing laminated crushing technology, the finished aggregate achieves uniform particle shape and a high cubic fraction, significantly enhancing the product's market value.

3. Rugged and Durable:The compact and rational single-cylinder structure effectively reduces failure points, ensuring the stability and lifespan of the equipment under long-term high-load operation.

4. Intelligent Safety:The hydraulic system features an automatic over-traffic protection function that quickly resets if a foreign object is encountered, minimizing unplanned downtime.

5. Worry-Free and Cost-Effective:The simplified structure facilitates maintenance, reduces daily operation and maintenance costs, and provides outstanding long-term economical performance.

| Model | Cavities | Feeding Size(mm) | Adjusting Range of Discharge Opening (mm) | Capacity(t/h) | Power(kw) |

|---|---|---|---|---|---|

|

CH440 (DG300) |

Extra Coarse - EC | 220 | 16-44 | 114-395 | 220 |

| Coarse - C | 175 | 13-44 | 101-378 | ||

| Medium - M | 157 | 13-38 | 97-328 | ||

| Medium Fine - MF | 125 | 13-38 | 114-299 | ||

| Fine - F | 80 | 8-32 | 90-251 |

| NO. | Product Name | Model | Quantity |

|---|---|---|---|

| 1 | Hopper | - | 1 |

| 2 | Vibrating Feeder | ZSW1142 | 1 |

| 3 | Jaw Crusher | PE750x1060 | 1 |

| 4 | Cone Crusher | CH-440 | 1 |

| 6 | Vibrating Screen | 4YK2470 | 1 |

| 7 | Belt Conveyor | B1000 | 8 |

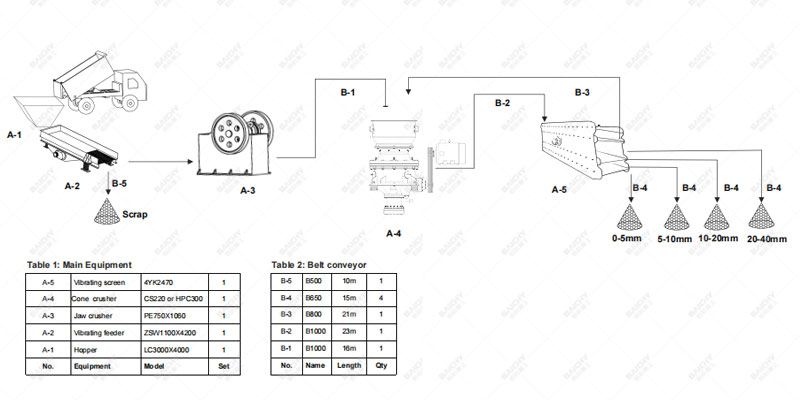

In medium-sized aggregate production projects, a well-designed and properly configured production line is key to achieving economic benefits. For limestone crushing lines with an output of 200-300 tons per hour, selecting efficient, stable, and well-shaped secondary and tertiary crushing equipment is crucial. The CH-440 single-cylinder hydraulic cone crusher is the ideal core option for limestone crushing in this capacity range.

A limestone production line with an output of approximately 250 tons per hour, centered around the CH-440, can be configured as follows:

1. Feeding and Primary Crushing: A vibrating feeder evenly feeds the raw ore to a jaw crusher (such as a PE-750x1060) for primary crushing.

2. Secondary and Tertiary Crushing Core: The primary crushed material (approximately 200mm or less) is conveyed by a belt conveyor to the CH-440 single-cylinder cone crusher for secondary and tertiary crushing. This is the key link in the entire production line, crushing the material to a size of less than 50mm.

3. Screening and Finishing: Crushed materials are graded on a vibrating screen. Aggregates that meet the required specifications (e.g., 0-5mm, 5-10mm, 10-20mm, 20-31.5mm) are transported to the finished product stockpile. Unqualified large particles are returned to the CH-440 via a belt conveyor for closed-circuit crushing.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!