Crawler Mobile Jaw Crusher

In today's rapidly developing construction, mining, and infrastructure sectors, mobile crushing and screening equipment is transforming traditional rock processing methods in unprecedented ways. As a professional manufacturer of mobile mining crushing equipment, we deeply understand the industry's urgent need for high efficiency, flexibility, and low operating costs. Mobile crushing and screening systems represent not only technological advancement but also a fundamental revolution in the traditional fixed production line model.

Traditional rock processing typically requires large fixed plants, complex infrastructure, and expensive material transportation systems. However, with the increasing scale of projects, stricter environmental requirements, and diversification of operating locations, the limitations of this model are becoming increasingly apparent. The emergence of mobile crushing and screening equipment perfectly addresses these pain points, integrating a complete processing production line onto a mobile platform, achieving a fundamental shift from "materials coming to the equipment" to "equipment going to the materials."

Technological Advantages: Why choose a mobile crushing and screening system?

Superior Mobility and Flexibility

The crawler-mounted mobile platform provides unparalleled site adaptability. Whether it's the roughest mining terrain, the most remote construction site, or a construction site with limited space, mobile crushing and screening equipment can be quickly deployed and put into operation immediately. This mobility means that the equipment can move in sync with the project progress, significantly reducing the distance of secondary material handling, thereby substantially lowering transportation costs and carbon emissions.

Integrated Intelligent Control System

Modern mobile crushing and screening equipment integrates advanced PLC automation control systems and remote monitoring technology. Operators can easily control the entire processing process through touch screens or wireless remote control devices, monitoring production status, equipment operating parameters, and maintenance needs in real time. The intelligent fault diagnosis system and early warning mechanism minimize unexpected downtime and ensure production continuity.

Modular Design and Rapid Relocation

Our equipment adopts a modular design concept, allowing different crushing and screening units to be quickly combined, disassembled, and reconfigured. When a project requires relocation, the entire system can be disassembled, transported, and reassembled within hours, while traditional fixed production lines may require weeks or even months for relocation. This flexibility allows a single set of equipment to serve multiple projects, significantly improving return on investment.

Actual Application Case Studies

Case Study 1: Granite Mine Crushing Project

In a large-scale granite mining project in South China, the client faced the challenges of dispersed ore bodies and long transportation distances. We configured a complete mobile crushing and screening production line for them, including a crawler-mounted jaw crusher, a cone crusher, and a three-layer screening station. After project implementation, material transportation costs were reduced by 65%, production efficiency increased by 40%, and the equipment investment payback period was shortened to 18 months.

Case Study 2: Urban Construction Waste Resource Utilization

A construction waste treatment center in a major city adopted our mobile impact crushing and screening system to process concrete, bricks, and other construction waste generated from demolition on-site. The system achieved a resource utilization rate of over 95%, and the produced recycled aggregates were directly used in urban road construction, creating significant economic and environmental benefits.

Product Portfolio Recommendations

Primary Crushing Solution: Crawler-mounted Jaw Crusher

Processing Capacity: 200-650 tons/hour

Maximum Feed Size: ≤1000mm

Applicable Materials: Granite, basalt, limestone, and other hard rocks

Core Advantages: Heavy-duty structural design, high crushing ratio, low energy consumption

Secondary and Fine Crushing Solution: Crawler-mounted Cone Crusher

Processing Capacity: 150-580 tons/hour

Output Particle Size: 0-60mm adjustable

Applicable Materials: Secondary crushing of medium-hard and above rocks

Core Advantages: Laminated crushing principle, excellent particle shape, convenient maintenance

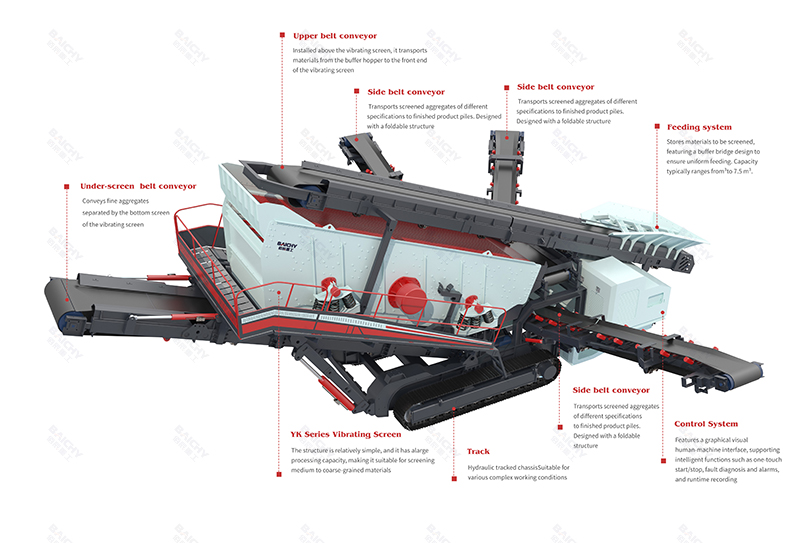

Screening and Classification Solution: Crawler-mounted Screening Station

Number of Screening Layers: 2-3 layers

Processing Capacity: 300-800 tons/hour

Screening Area: 4.5-22.5 square meters

Core Advantages: High-efficiency screening, simultaneous production of multiple finished product specifications

Frequently Asked Questions

What are the maintenance costs of mobile crushing and screening equipment?

The maintenance costs of mobile crushing and screening equipment are usually lower than traditional fixed production lines. The modular design makes the replacement of key components more convenient, and the intelligent monitoring system can provide early warnings of potential faults. Under normal maintenance conditions, the annual maintenance cost of the equipment is usually controlled within 3-5% of the equipment value.

How is the reliability of the equipment guaranteed in harsh environments?

We utilize heavy-duty design standards, and key components such as bearings, hydraulic systems, and electrical components are selected from leading international brands. The equipment is equipped with comprehensive protective devices, including dust seals, anti-vibration measures, and all-weather protective coatings, enabling stable operation in ambient temperatures ranging from -20℃ to 50℃.

How do we guarantee the stability of output particle size and gradation?

Through precise crushing chamber design, intelligent hydraulic adjustment systems, and efficient screening control, we ensure high stability of output particle size. The screening system adopts a multi-layer design, combined with adjustable screen inclination and amplitude, to accurately control the gradation ratio of different specifications of finished products.

Future Development Trends

With the continuous development of 5G technology, the Internet of Things, and artificial intelligence, intelligence and automation will become the main development direction of mobile crushing and screening equipment. Future equipment will have stronger self-learning capabilities, able to automatically optimize operating parameters based on material characteristics, achieving truly intelligent production. At the same time, the application of electrification and hybrid power technologies will further improve the environmental performance and economic efficiency of the equipment, meeting increasingly stringent emission standards worldwide.

As a technology leader in the industry, we continuously invest in R&D resources, committed to providing customers with more efficient, intelligent, and environmentally friendly mobile crushing and screening solutions. Whatever rock processing challenges you face, we are confident in providing the most suitable equipment and the most professional service support.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!