For companies planning large-scale, long-term mining or processing of construction aggregates, stationary crushing plants have always been the backbone of their core production systems. Unlike mobile crushing plants, they represent a permanent or semi-permanent investment in heavy assets. Therefore, the "price of a stationary crushing plant" is by no means a simple number, but a complex entity composed of multiple in-depth factors. This article will provide you with an in-depth analysis of its price structure, advantages, and applicable scenarios, helping you make a more informed investment decision.

I. Overview and Price Structure Analysis of Stationary Crushing Plants

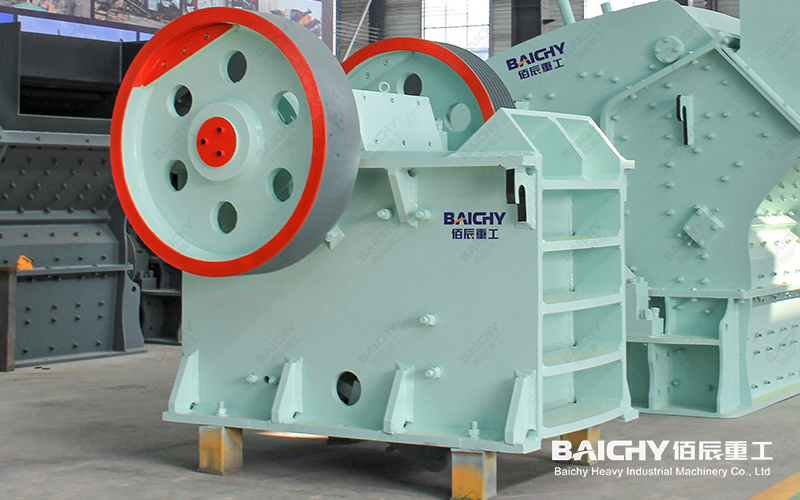

A stationary crushing plant, as the name suggests, refers to a complete production system where all main crushing, screening, and conveying equipment is permanently installed on a concrete foundation or steel structure. It is typically used in mines, large quarries, cement plants, or large-scale construction sites, and is designed for a service life of several decades.

What factors mainly affect the price?

The price range can vary from hundreds of thousands of dollars to millions of dollars, depending on the following core variables:

Capacity and Scale: This is the primary factor determining the price. A production line with a capacity of 100 tons per hour and one with a capacity of 1000 tons per hour will have vastly different equipment specifications, model numbers, motor power, and steel structure platform sizes, resulting in a significant price difference.

Raw Material Characteristics and Finished Product Requirements: The hardness (such as granite, limestone), particle size, and moisture content of the raw materials, as well as the required particle size, shape, and gradation of the finished product, directly determine the complexity of the crushing process. Whether multi-stage crushing is required (such as jaw crusher + cone crusher + sand making machine), and whether additional soil removal, screening, or sand washing is needed, will significantly affect the total price.

Core Equipment Selection and Brand: The price difference between equipment from different brands and with different technological levels is huge. For example, choosing a high-performance hydraulic cone crusher or a traditional spring cone crusher, or choosing a high-end brand or an economical brand, can lead to a 30% or even higher difference in the core cost of the production line.

Automation and Control System: The price difference between a basic electrical control system and a complete central intelligent control system (with remote monitoring, fault diagnosis, automatic adjustment, etc.) is significant. The latter can greatly improve efficiency and management levels, but requires a higher initial investment.

Supporting Facilities and Installation: The price usually does not include civil engineering (foundations, factory buildings), power facilities (high-voltage access, transformers), environmental protection facilities (dust removal, noise reduction systems), installation and commissioning, and personnel training costs. These "hidden investments" may account for 20%-40% of the total equipment cost and must be fully considered in the budget.

II. Core Advantages of Fixed Production Lines

Despite higher initial investment and fixed costs, fixed production lines have irreplaceable advantages in specific scenarios:

Extremely high production stability and continuous operation capability: Designed for 7x24 hour high-intensity operation, the equipment is stable, with a low failure rate, suitable for large-scale, long-cycle production, resulting in lower production costs per unit of time.

Superior finished product quality and process flexibility: The fixed site allows for the design of more complex and optimized process flows. Through multi-stage crushing and precision screening, it is easier to stably control the finished product particle shape and gradation, producing high-value-added products.

Lower long-term operating costs: Significant economies of scale, with per-ton costs for electricity consumption and wear parts typically lower than mobile equipment. Equipment maintenance is more convenient with a fixed location.

Powerful raw material processing capabilities: Capable of handling extra-large raw materials and can form an efficient logistics network through a mature belt conveyor system, suitable for processing large quantities of materials.

| Key Words |

Considering a Stationary Crushing Plant? Here’s the REAL Cost Breakdown You Must Know Before Investing |

| Product Model |

Stone Crushing Plant |

| Capacity |

0-2000t/h |

| Core Advantages |

Multi-stage fragmentation and reshaping |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

III. Application Cases and Equipment Recommendation Ideas

Case Scenario: A large granite quarry aims to produce 500 tons of high-quality aggregate and manufactured sand per hour.

Recommended Process: A combination of "feeder + heavy-duty jaw crusher (coarse crushing) + medium-to-large multi-cylinder hydraulic cone crusher (medium and fine crushing) + vertical shaft impact crusher (sand making and shaping) + multi-layer vibrating screen". Complete with a belt conveyor system, centralized electrical control room, and dust removal system.

Price Influencing Factors: This line requires extremely high wear resistance and stability of the equipment. The core crushing equipment needs to be heavy-duty models, so the investment focus should be on the core machinery. Environmental protection investment is also a necessity.

IV. Fixed vs. Mobile: How to Choose?

As a manufacturer of mobile crushing equipment, we objectively suggest: the choice depends on the nature of your project.

Choosing a Fixed Production Line: This is the undisputed choice when your material source is fixed, the mining cycle lasts for more than 5 years, you are pursuing maximum economies of scale and the lowest cost per ton, and you have the necessary site and power conditions.

Considering a Mobile Crushing Plant: This is suitable when your project is decentralized (multiple mining points), requires frequent relocation, has weak site infrastructure, or has a short project cycle. The advantages of a mobile plant lie in rapid deployment, flexible configuration, and reduced civil engineering and material transportation costs, thus achieving "crushing where mining takes place." Although the single-machine capacity may be limited, the overall project investment return cycle may be faster.

V. Frequently Asked Questions (FAQ)

Q1: What is the approximate total investment for a medium-sized fixed crushing production line?

A1: This is a very common question, but the answer varies widely. For a medium-sized production line with a capacity of 200-300 tons per hour, the reference price for the equipment alone (excluding civil engineering and power) may range from US$500,000 to US$1,500,000. The final price must be determined based on a detailed assessment of production needs and process design.

Q2: What is the typical return on investment period for a fixed production line?

A2: The return on investment period is affected by multiple factors, including material value, operating costs, market price, and capacity utilization rate. Under good operation and stable market conditions, large production lines typically expect to recover their investment within 2-4 years. A detailed return on investment analysis should be conducted during the project feasibility study phase.

Q3: Can we start with a mobile crushing plant and then switch to a fixed one in the future?

A3: From a design perspective, standard mobile plants and fixed line equipment have different integration methods, making direct conversion impractical. However, one strategy is to initially use a high-capacity mobile crushing plant (such as a crawler-mounted jaw crusher + cone crusher combination) for rapid commissioning, verifying the material source and market; once the business is stable, then plan and build a fixed production line. The mobile equipment can then be transferred to a new project site, achieving flexible asset utilization.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!