Shaking table, gravity separator, mineral sorting equipment

In the crushing and grinding process of mines, equipment such as crushers and ball mills are responsible for processing raw ore into fine particles. However, these particles are usually a mixture of various useful minerals and useless gangue. The shaking table, as a key gravity separation device, is valuable for its efficient separation and enrichment of these mixed particles. It is a crucial step in extracting the final concentrate from the grinding product and increasing its added value.

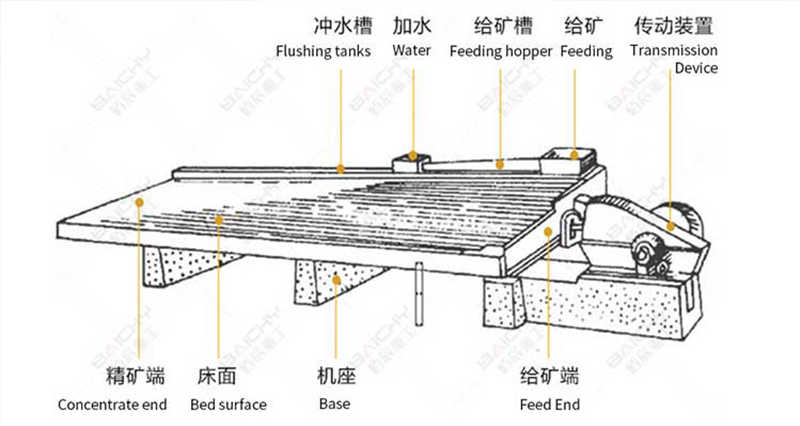

Shaking Table Overview A shaking table, also known as a gravity separation table, is a device that uses the combined action of mechanical shaking and water washing to separate mineral particles based on their density, size, and shape. Its core components include the bed surface, transmission device, feed trough, and water trough. During operation, the bed surface undergoes asymmetrical reciprocating motion, while water flows laterally along the inclined bed surface. Mineral particles with different characteristics produce different trajectories under the action of mechanical and hydraulic forces, thus enriching in different areas of the bed surface and achieving the purpose of separation.

structural diagram of the shaking table

Working Principle Overview

Material is uniformly fed into the feed trough and, on a bed surface with ribs or grooves, is subjected to the combined effects of shaking and transverse water flow. High-density, small-sized particles settle to the bottom and move towards the concentrate end along the gaps between the ribs; low-density, large-sized particles are carried towards the tailings end by the water flow. Ultimately, a clear separation zone is formed on the bed surface, achieving the separation of concentrate, middlings, and tailings.

Advantages of Shaking Tables

After 20 years of technological iteration and field practice, we have recognized the following significant advantages of modern shaking tables:

High Separation Precision: Shaking tables can achieve "layer-by-layer screening" of mineral particles, with excellent separation effect for fine-grained minerals (especially rare metals such as tin, tungsten, titanium, tantalum, and niobium), resulting in high-grade concentrate and high recovery rates.

Low Operating Costs: No chemical reagents are required; the main power source is electricity. The equipment structure is relatively simple, resulting in low maintenance costs and easy operation, making it ideal for small and medium-sized beneficiation plants or cost-sensitive projects.

No Environmental Pollution

As a physical separation method, the shaking table does not generate toxic or harmful chemical wastewater or exhaust gas during the entire separation process, meeting the environmental protection requirements of green mines.

Case 1: A Tin Mine Beneficiation Plant in Southeast Asia

This plant has a processing capacity of 100 tons/day. The raw ore is crushed by a jaw crusher and a cone crusher, then ground by a ball mill, and finally separated using our provided 6-S shaking tables. Ultimately, the cassiterite concentrate grade increased from 0.5% in the raw ore to 65%, with a recovery rate exceeding 85%, bringing significant economic benefits to the client.

Case 2: A Tungsten Mine Project in Africa

This project initially used a simple gravity separation process, resulting in unsatisfactory recovery rates. We provided a combined process including spiral sluice for roughing and fine shaking tables for cleaning. After the upgrade, the tungsten concentrate recovery rate increased by 15 percentage points, proving the irreplaceable role of the shaking table in the fine separation stage.

Related Equipment Recommendations

An efficient beneficiation plant is the result of different equipment working together. In addition to the core shaking table, we recommend you consider the following related equipment to build a complete production line:

• Crushing equipment: Jaw crusher (coarse crushing), cone crusher/impact crusher (medium and fine crushing)

• Grinding equipment: Ball mill, rod mill

• Other sorting equipment: Magnetic separator (for iron minerals), flotation machine (for sulfide minerals, etc.)

• Feeding and conveying equipment: Vibrating feeder, belt conveyor

Frequently Asked Questions (FAQ)

1. What is the processing capacity of a shaking table?

The processing capacity of a shaking table is closely related to its model and the particle size of the feed. Small laboratory shaking tables may only have a processing capacity of tens of kilograms per hour, while large industrial shaking tables (such as 6-S shaking tables) can reach 1-2 tons per hour when processing appropriately sized mineral sands.

2. Which minerals are shaking tables suitable for separating?

Shaking tables are mainly suitable for separating minerals with large density differences. It is widely used for the separation of rare and precious metal ores such as wolframite, cassiterite, placer gold, ilmenite, zircon, chromite, and tantalum-niobium ore. However, its effectiveness may be poor for minerals with very small density differences (such as galena and sphalerite).

3. How to improve the separation efficiency of a shaking table?

The key to improving efficiency lies in stable feed (concentration and particle size), appropriate bed lateral slope, and stroke/frequency adjustment. Regular maintenance to ensure a smooth bed surface and proper operation of the transmission mechanism is also crucial. We will provide comprehensive operation training upon equipment delivery.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!