Have Any Questions!

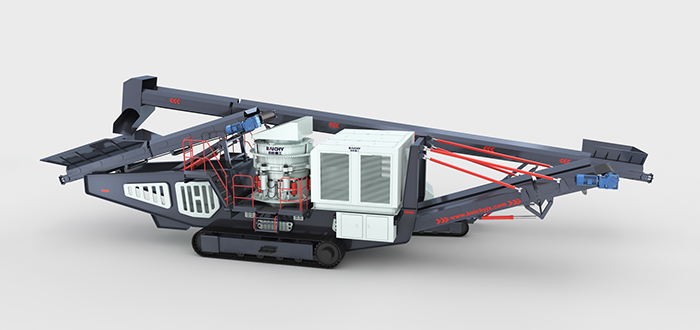

Crawler cone mobile crushing station is a mobile crushing equipment that integrates cone crusher and crawler walking device. It is widely used in mining, construction waste treatment, road construction and other fields. It has the characteristics of high efficiency, flexibility and strong adaptability.

• Cone crusher: adopts the principle of lamination crushing, suitable for medium and high hardness materials (such as granite, basalt), with excellent finished product shape and stable gradation.

• Crawler chassis: hydraulic drive, remote control operation, adaptable to complex terrain (slope up to 15°), no trailer required for transfer.

• Feeding system: pre-screening of vibrating feeder to reduce over-crushing.

• Control system: PLC intelligent control, optional remote monitoring, real-time adjustment of parameters (discharge port, speed, etc.).

| Model | Feeder | Cone Crusher | Main Discharge Belt | Inspection Screen | Discharge Belt Under Screen | Transition Belt1 | Transition Belt2 | Screen Front Side Discharge Belt | Return Belt Conveyor | Capacity |

|---|---|---|---|---|---|---|---|---|---|---|

| YMH20S | 1000x7m | HP200 | B1000x9.5m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.2m | 100-225t/h |

| YMH20 | 1000x7m | HP200 | B1000x10m | — | — | — | — | — | — | 100-225t/h |

| YMH30S | 1000x7m | HP300 | B1000x9.5m | 2YK1436 | B1200x6.5m | B500x2m | B500x2m | B500x4.5m | B500x8.2m | 150-380t/h |

| YMH30 | 1000x7m | HP300 | B1000x10m | — | — | — | — | — | — | 150-380t/h |

| YMH40S | 1200x8m | HP400 | B1200x12m | 2YK1545 | B1200x6.5m | B650x2m | B650x2m | B650x4.5m | B650x9.2m | 200-450t/h |

| YMH40 | 1200x8m | HP400 | B1200x10m | — | — | — | — | — | — | 200-450t/h |

Crawler-type cone mobile crushing station is a mobile device that integrates cone crusher and crawler walking, suitable for mining, construction waste recycling and other scenes, with a processing capacity of 50-400 tons/hour, remote intelligent control, and flexible transfer.

• Mobility: No infrastructure is required, it can be operated upon arrival at the site, saving time and transportation costs.

• Versatility: It can be matched with cone crushers of different chamber types (such as standard type, short head type) to meet the needs of coarse or fine crushing.

• Environmental protection and energy saving: Some models are equipped with noise reduction system and spray dust suppression device, which meets environmental protection requirements.

• High automation: Over-iron protection and automatic cavity cleaning function reduce the risk of downtime.

• Mining: Crushing ore directly on site to reduce the transportation cost of raw ore.

• Construction waste recycling: Mobile processing of concrete, bricks and tiles to produce recycled aggregates.

• Sand and gravel aggregate production: Matching with mobile screening station to form a flexible production line.

The crawler-type cone mobile crusher uses a high-performance cone crusher as the core and is equipped with a heavy-duty crawler chassis system. It can achieve 360° free transfer operation under complex working conditions such as mining, aggregate processing, and urban building demolition.

Compared with traditional fixed production lines, this equipment can reduce transportation costs by more than 60%, and the processing capacity of a single unit is 80-350t/h. It is a mobile crushing solution for green mine construction and urban renewal projects. It supports customized feed pre-screening modules and fine material recovery systems to meet customers' differentiated production needs.

Thank you for your interest in Baichy Machinery. If you want to know more about our crushers and industrial grinding equipment.

Contact us now to find out what we can do for you!