YGM Grinding Mill | Comprehensive Guide

In industries such as mining, building materials, and chemicals, fine grinding of materials is a key step in enhancing product added value. As a manufacturer of mining crushing and grinding equipment with 20 years of experience in the industry, we have witnessed the development and evolution of various grinding technologies. Among them, the YGM Grinding Mill (high-pressure suspension roller mill) has consistently held an important position in the medium-fine grinding market due to its excellent stability, wide applicability, and superior cost-effectiveness. This article will provide a comprehensive analysis of the YGM grinding mill, revealing why it has become a reliable choice for many companies.

Market Positioning and Value of the YGM Grinding Mill

The YGM Grinding Mill is not an unfamiliar name; it represents a mature and continuously optimized grinding technology. In the grinding of hundreds of materials with a Mohs hardness below 9.3 and a moisture content below 6%, from traditional limestone, calcite, and barite to cutting-edge applications such as slag, water slag, and activated carbon, the YGM grinding mill excels. Its core value lies in achieving a perfect balance between efficiency, energy consumption, and maintenance costs within the 80-600 mesh fineness range, making it an ideal solution for medium-capacity grinding projects.

How does the YGM grinding mill work?

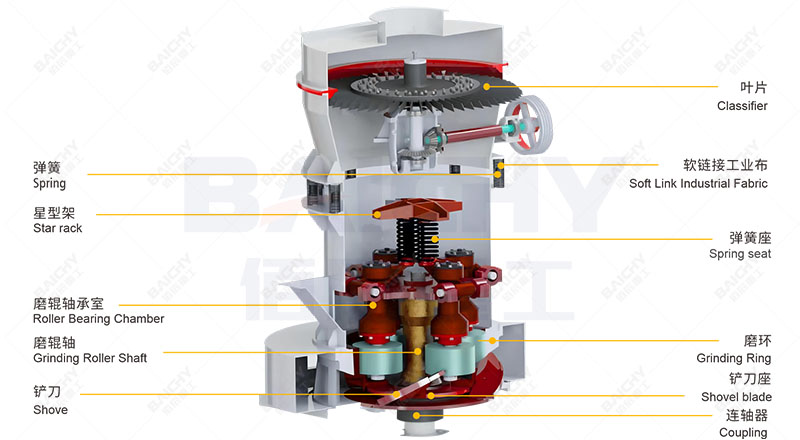

The YGM high-pressure suspension roller mill is a structural innovation based on the traditional Raymond mill. The entire system mainly consists of the main unit, reducer, analyzer, cyclone separator, piping system, blower, dust collector, jaw crusher (optional), bucket elevator, electromagnetic vibrating feeder, and electrical control system, forming a highly efficient closed-loop grinding production unit.

Structural diagram of YGM grinding equipment

Core Working Principle

1. Crushing and Feeding: Large pieces of material are initially crushed by the jaw crusher, then transported to the storage silo by the bucket elevator, and then evenly and quantitatively fed into the main grinding chamber by the feeder.

2. Grinding Process: In the grinding chamber, the material is scooped up by the blades and scattered between the grinding rollers and the grinding ring. Under the centrifugal force generated by the rotation of the central shaft, the grinding rollers swing outward and press tightly against the grinding ring, while simultaneously rotating around their own axis. The material is crushed and pulverized in this process.

3. Grading and Collection: The pulverized powder is blown up by the blower airflow and graded by an analyzer placed above the main unit. Powder meeting the fineness requirements passes through the analyzer and enters the cyclone separator for collection; excessively coarse powder falls back into the grinding chamber for regrinding.

Five Irreplaceable Core Advantages

As an experienced manufacturer, we understand that equipment reliability is crucial to our customers' financial success. Our YGM Grinding Mill boasts the following significant advantages:

1. Excellent Stability and Durability

Core grinding components (grinding rollers, grinding rings) are made of high-quality alloy steel and undergo special processing, resulting in extremely high wear resistance and a significantly extended service life, ensuring continuous and stable production.

2. High Efficiency and Energy Saving, Low Operating Costs

The unique grinding chamber curve design and efficient cyclone separation system reduce airflow resistance and circulating load. Under the same fineness conditions, it consumes less energy and produces higher output than traditional airflow mills, effectively helping customers save production costs.

3. Flexible Finished Product Fineness Adjustment

The finished product fineness can be flexibly adjusted between 80-600 mesh. Different finenesses can be obtained simply by adjusting the analyzer's speed, making it a multi-functional machine to meet perse production needs.

4. Excellent Environmental Performance

The entire system is equipped with a high-efficiency pulse dust collector, and the pipe connections use a sealed structure, minimizing dust leakage and ensuring a clean working environment that fully complies with national environmental standards.

5. Intelligent Electrical Control System

The system adopts a centralized electrical control system, enabling unmanned operation in the workshop with a high degree of automation. Fewer maintenance points and simpler operation reduce labor costs and operational complexity.

Grinding equipment customer site

Successful Application Cases

Our YGM grinding mills have served numerous projects worldwide. Below are two typical case studies:

• Case Study 1: A limestone powder processing plant in Hubei, China

◦ Material: Limestone

◦ Finished product fineness: 250 mesh (D90)

◦ Output: 8-9 tons/hour

◦ Feedback: The equipment has demonstrated excellent stability over three years of operation, with a zero electrical system failure rate, uniform roller wear, and long maintenance cycles. The customer is very satisfied with the powder output efficiency and energy-saving effects.

• Case Study 2: A slag micronization project in Southeast Asia

◦ Material: Blast furnace slag

◦ Finished product fineness: 420 mesh

◦ Output: 5-6 tons/hour

◦ Feedback: The YGM grinding mill successfully transformed industrial waste slag into high-value admixtures. The product has uniform fineness and high activity, creating significant economic benefits for the customer and contributing to resource recycling.

Recommended Equipment

To build a complete grinding production line, the YGM Grinding Mill typically works in conjunction with the following equipment:

• Jaw Crusher: Used for primary crushing of large materials, providing the mill with a suitable particle size feed.

• Bucket Elevator and Electromagnetic Vibrating Feeder: Enables vertical conveying and stable, uniform feeding of materials.

• Pulse Jet Bag Filter: Ensures a clean production environment and achieves green production.

Frequently Asked Questions (FAQ)

1. What materials are best suited for grinding with the YGM grinding mill?

The YGM Grinding Mill is suitable for non-flammable and non-explosive mineral materials with a Mohs hardness below 9.3 and a moisture content below 6%. Common materials include: limestone, calcite, barite, potassium feldspar, talc, marble, dolomite, gypsum, activated carbon, bentonite, slag, water slag, and hundreds of other materials.

2. Is the installation and commissioning of the equipment complex? Do you provide support?

As a professional mining equipment manufacturer, we provide a one-stop service, from factory layout design and basic drawings to equipment installation guidance, commissioning, and operator training. Our engineers can provide full technical support on-site or via video to ensure rapid equipment commissioning.

3. What is the service life of core wear parts (such as grinding rollers and grinding rings)?

This mainly depends on the hardness, abrasiveness, and workload of the grinding material. When grinding medium-hard limestone (Mohs hardness 3-4), a set of high-quality grinding rollers and grinding rings typically has a continuous service life of 1-2 years under normal maintenance. We provide original equipment parts to ensure that the equipment performs like new after replacement.

Choosing a reliable grinding mill is the cornerstone of investing in a profitable production line. With 20 years of technical experience, we offer not only the YGM Grinding Mill, but also a complete solution including technical consultation, solution design, and lifetime after-sales service. If you are looking for a stable, efficient, and economical grinding solution, please contact us and let us help you succeed with our expertise.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!