20 T/H Limestone Processing Plant Solution - Jaw Crusher + Raymond Mill Production Line

I. Project Requirements Analysis

This project addresses the needs of an Ethiopian client for a 20-ton/hour limestone processing plant. This is a typical small-to-medium-sized non-metallic mineral grinding project. Limestone, a soft material with a Mohs hardness of 3-4, is well-suited for the classic configuration of a jaw crusher + Raymond mill. This solution features moderate investment, simple operation, and low maintenance costs, making it particularly suitable for startups or small-to-medium-sized building materials production projects.

II. Equipment Configuration Scheme

2.1 Jaw Crusher Selection

| Recommended Model | PE400×600 |

| Feed Size | ≤350mm |

| Discharge Size | 40-100mm (Adjustable) |

| Production Capacity | 20-50t/h |

| Motor Power | 30-37kW |

| Core Advantages | Simple structure, large crushing ratio, wear parts life 6-12 months |

As a coarse crushing device, the jaw crusher can crush large limestone raw materials into uniform particles of 30-50mm, providing an ideal feed size for subsequent Raymond milling.

2.2 Raymond Mill Selection

| Recommended Models | YGM160 or YGM190 |

| Production Capacity | 15-25 t/h (325 mesh limestone) |

| Finished Product Fineness | Adjustable 80-400 mesh |

| Feed Size | ≤25mm |

| Total Power | 264-537kW |

| Power Consumption per Ton | Approximately 25 kWh (calculated at 0.5 yuan/kWh, electricity cost per ton is approximately 12.5 yuan) |

The Raymond mill achieves fine grinding through the crushing action of grinding rollers and grinding rings. Combined with a built-in grading system, it can precisely control the fineness of the finished product, meeting the fineness requirements of limestone powder in various industries.

2.3 Supporting Auxiliary Equipment

Complete Production Line Configuration List:

| Equipment Name | Model/Specification | Quantity | Functional Description |

| Jaw Crusher | PE400×600 | 1 unit | Coarse crushing to 30-50mm |

| Bucket Elevator | TH315 | 1 unit | Vertical material conveying |

| Electromagnetic Vibrating Feeder | GZD850×3000 | 1 unit | Uniform quantitative feeding |

| Raymond Mill Main Unit | YGM160 or YGM190 | 1 unit | Core grinding equipment |

| Cyclone Collector | XF-3000 | 1 set | Primary powder collection |

| Pulse Bag Filter | DMC-120 | 1 set | Secondary dust removal, emission ≤30mg/m³ |

| Blower | 9-19-8C | 1 unit | Provides system airflow |

| Electrical Control System | PLC Control | 1 set | Automated control |

20 T/H Limestone Processing Plant Solution - Jaw Crusher + Raymond Mill Production Line

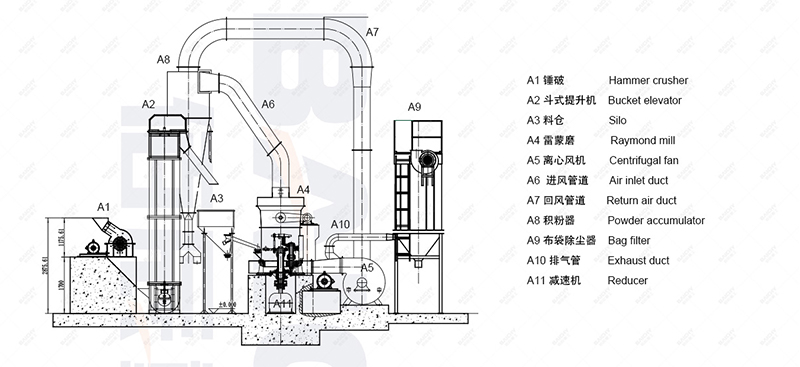

III. Detailed Process Flow

3.1 Crushing Stage

Large limestone raw materials (≤500mm) are coarsely crushed to 30-50mm using a jaw crusher. This step directly determines the subsequent grinding efficiency. If the raw material moisture content exceeds 5%, a drying process is required to prevent material adhesion to the grinding ring and affect the grinding effect.

3.2 Grinding Stage

The crushed limestone is fed into the hopper by a bucket elevator and then uniformly and quantitatively fed into the Raymond mill main unit by an electromagnetic vibrating feeder. Under centrifugal force, the grinding rollers press tightly against the grinding ring, forming a unique layered crushing effect, saving more than 30% energy compared to traditional impact crushing.

3.3 Classification and Collection

The pulverized powder is carried by the airflow of a blower and enters an analyzer for classification. By adjusting the analyzer speed, the fineness of the finished product can be precisely controlled between 80-325 mesh. Qualified fine powder is carried by the airflow into a cyclone collector for separation and collection, while residual micro-powder is filtered a second time by a pulse bag filter to ensure that the dust emission concentration is ≤30mg/m³.

IV. Equipment Advantages and Features

4.1 Jaw Crusher Advantages

• High crushing ratio: Crushing ratio can reach 4-6, capable of crushing large pieces of limestone to the ideal particle size in one pass.

• Wear-resistant and durable: High manganese steel jaw plates have a lifespan of 6-12 months, resulting in low maintenance costs.

• Simple structure: Easy operation and maintenance, low failure rate, suitable for harsh mining environments.

4.2 Raymond Mill Advantages

• High efficiency and energy saving: Layered crushing principle, unit energy consumption is reduced by 15-20% compared to traditional ball mills.

• Adjustable fineness: By adjusting the analyzer speed, the finished product fineness can be adjusted arbitrarily between 80-400 mesh.

• Environmental compliance: Pulse bag filter ensures dust emission concentration ≤30mg/m³, meeting environmental protection requirements.

• High degree of automation: PLC control system realizes one-button start/stop, fault alarm, and remote monitoring.

4.3 Overall Line Advantages

• Moderate Investment: The total investment for a 20-ton/hour production line is approximately 800,000-1,200,000 RMB, offering high cost-effectiveness.

• Small Footprint: The entire line adopts a vertical layout, occupying only 200-300 square meters.

• Simple Operation: Daily operation and maintenance can be completed by 1-2 people, resulting in low labor costs.

• Stable Finished Product Quality: Through precise grading control, the finished product has uniform fineness, meeting the requirements of industries such as construction and chemicals.

20 T/H Limestone Processing Plant Solution

V. Successful Case Studies

5.1 Sichuan Deyang Highway Mineral Powder Grinding Project

• Processed Material: Limestone

• Finished Product Fineness: 200 mesh

• Production Capacity: 20t/h

• Equipment Configuration: PE400×600 Jaw Crusher + YGM160 Raymond Mill

• Operational Results: The equipment operated continuously for 300 days without failure, with power consumption per ton controlled below 25kW·h, and a finished product qualification rate of over 98%.

5.2 Guangxi Limestone Grinding Production Line

• Processed Material: Limestone

• Finished Product Fineness: 325 mesh

• Production Capacity: 25t/h

• Equipment Configuration: PE500×750 Jaw Crusher + YGM190 Raymond Mill

• Operational Results: 7200 hours of annual operation, wear-resistant parts lifespan meets expectations, maintenance costs reduced by 30% compared to traditional equipment

VI. Investment Return Analysis

6.1 Investment Cost Composition

| Item | Cost Range | Description |

| Equipment Procurement | 800,000-1,200,000 RMB | Includes jaw crusher, Raymond mill, dust collector, and other complete equipment |

| Installation and Commissioning | 30,000-50,000 RMB | Includes foundation construction, equipment installation, commissioning training |

| Civil Engineering | 100,000-150,000 RMB | Plant, silos, foundations, etc. |

| Other Costs | 50,000-80,000 RMB | Power capacity expansion, environmental approvals, etc. |

| Total | 980,000-1,480,000 RMB |

6.2 Operating Cost Analysis

| Item | Cost Standard | Annual Cost (based on 300 days/year) |

| Electricity Cost | 0.5 RMB/kWh, 25 kWh per ton of electricity consumption | 20t/h × 8h × 300 days × 25 degrees × 0.5 yuan = 600,000 yuan |

| Labor | 2 people × 6000 yuan/month | 144,000 yuan |

| Wear-resistant parts replacement | 3-5 sets per year | 30,000-50,000 yuan |

| Other maintenance | Routine maintenance | 20,000-30,000 yuan |

| Annual operating cost | 794,000-824,000 yuan |

6.3 Profit Analysis

• Product selling price: Market price of 325 mesh limestone powder is approximately 150-200 yuan/ton

• Annual output: 20t/h × 8h × 300 days = 48,000 tons

• Annual output value: 48,000 tons × 180 yuan/ton = 8,640,000 yuan

• Annual profit: 8,640,000 yuan - 824,000 yuan = 7,816,000 yuan

• Investment recovery period: Approximately 2-3 months

VII. Frequently Asked Questions (FAQ)

Q1: What if the moisture content of the limestone raw material exceeds 6%?

A: When the moisture content of limestone raw materials exceeds 6%, a drying process needs to be added before the jaw crusher. A rotary drum dryer or hot air furnace can be used for pre-drying to control the material moisture content below 6% before it enters the Raymond mill. Otherwise, the material is prone to adhering to the grinding ring, leading to decreased output and increased energy consumption.

Q2: What are the reasons and solutions for Raymond mill not producing powder or producing too little powder?

A: Common reasons include:

1. Poor sealing of the powder lock: Check and adjust the powder lock seal to ensure no air leakage.

2. Severely worn shovel blades: Replace with new shovel blades to ensure the material can be scooped up normally.

3. Blocked air ducts: Clean the accumulated powder in the air ducts to maintain unobstructed airflow.

4. Improper fan airflow: Adjust the fan airflow to the appropriate range.

Q3: How to extend the service life of equipment?

A: We recommend the following measures:

1. Regular lubrication: Add oil at the specified time and amount, and clean the bearings regularly.

2. Check fasteners: Check the anchor bolts and connecting bolts for looseness every shift.

3. Monitor operating parameters: Monitor the main unit current and bearing temperature in real time, and handle any abnormalities promptly.

4. Regularly replace wear parts: Replace wear parts such as grinding rollers, grinding rings, and scrapers according to their service life.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!