Mining Magnetic Separator Manufacturer | High Recovery Rate

In the development and utilization of mineral resources, magnetic separators play a crucial role. They are highly efficient mineral processing equipment that utilizes the differences in magnetic properties of materials, separating them under the combined action of magnetic force and other forces (such as gravity and centrifugal force). Simply put, it is a machine capable of precisely separating magnetic minerals (such as magnetite and titanomagnetite) from non-magnetic minerals (such as quartz and feldspar) or weakly magnetic minerals. For any modern mineral processing plant pursuing high recovery rates, high-grade concentrates, and low operating costs, selecting a suitable magnetic separator is a key step in improving overall economic efficiency.

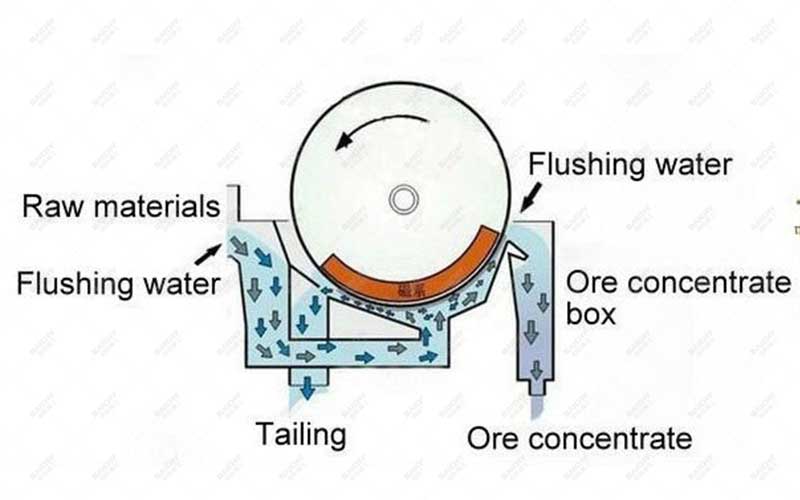

How do magnetic separators work? — Overview of core technology principles

The working principle of a magnetic separator is based on the magnetic force in physics. Although there are various types depending on the structure and the materials processed, the core process remains the same.

1. Feeding and Preparation

After crushing and grinding to achieve inpidual separation, the raw ore is uniformly fed into the separation zone of the magnetic separator in the form of a slurry (mixed with water) or dry powder.

2. Magnetic Field Separation

Within the separation zone, the magnetic separator generates a non-uniform magnetic field of controllable intensity through its magnetic system. When mineral particles pass through this magnetic field, minerals with strong magnetism (magnetic materials) are magnetically attracted (e.g., on the surface of the drum in a drum magnetic separator), while minerals with weak magnetism or no magnetism (non-magnetic materials) move along their own trajectories under the influence of gravity and centrifugal force.

3. Concentrate and Tailings Separation

The attracted magnetic minerals rotate with the magnetic system (or drum) and are carried away from the magnetic field area. The magnetic force disappears, and they are discharged into the concentrate trough, becoming a high-grade concentrate product. Non-magnetic minerals are discharged as tailings from another outlet. This process achieves efficient and continuous mineral separation.

Working-principle-of-magnetic-separator

Why Choose Our Mining Magnetic Separator?

With 20 years of professional manufacturing experience, we deeply understand the unique needs of different mines and different mineral types. Our mining magnetic separators offer the following significant advantages:

• High magnetic field strength and gradient: Utilizing high-performance rare-earth neodymium iron boron magnetic materials, the high magnetic field strength and rational magnetic circuit design ensure consistently stable magnetic force, guaranteeing excellent recovery of fine and micro-fine magnetic minerals.

• High recovery rate and high grade: Optimized tank structure and separation process design minimize mechanical entrainment and water entrainment, thus ensuring both high recovery rate of magnetic minerals and high grade of concentrate.

• Energy saving, environmental protection, and low operating costs: The equipment consumes little power and features a fully enclosed structure, effectively reducing dust and water pollution. Long-lasting wear parts significantly reduce maintenance costs and downtime for our customers.

• High degree of automation and intelligence: Automatic control systems can be integrated according to customer needs, enabling real-time monitoring and adjustment of parameters such as feed rate, magnetic field strength, and liquid level. Operation is simple; one person can operate multiple machines.

Success Story Sharing – Witnessing Strength, Creating Value

• Case Study 1: Upgrading Project of a Large Iron Ore Beneficiation Plant

◦ Challenge: The existing magnetic separator was outdated, resulting in low recovery rate, substandard concentrate grade, and high energy consumption.

◦ Solution: We provided them with three CTB-1230 permanent magnet drum magnetic separators for primary roughing and secondary cleaning.

◦ Results: Iron concentrate grade increased from 58% to over 65%, recovery rate improved by 12 percentage points, resulting in significant annual production and efficiency gains. The client was very satisfied.

• Case Study 2: Quartz Sand Purification Project

◦ Challenge: The client needed to remove weakly magnetic iron-containing impurities from quartz sand to meet high-end glass raw material standards.

◦ Solution: We recommended the RCYD series permanent magnet self-unloading magnetic separator for dry iron removal.

◦ Results: Iron content in quartz sand decreased from 0.15% to below 0.045%, significantly increasing product value. Recommended Equipment – Building a Complete Mineral Processing Solution

Magnetic separators for mining are typically a core component of a mineral processing production line. To achieve optimal separation results, we recommend considering the following complementary equipment:

• Jaw Crusher & Cone Crusher: Used for primary and secondary crushing of ores.

• Ball Mill & Classifier: Used to grind crushed ores to the required particle size, achieving liberation of inpidual particles.

• Flotation Machine: Used to separate non-magnetic or non-ferrous metal minerals.

• Thickener & Filter: Used to dewater and dry the separated concentrate.

We can provide you with a one-stop mineral processing solution, from experimental analysis and process design to complete equipment supply, installation, and commissioning.

Frequently Asked Questions (FAQ)

Q1: What is the difference between wet magnetic separators and dry magnetic separators? How should I choose?

A: The main difference lies in the separation medium. Wet magnetic separators use water as a medium and are suitable for ores with finer particle sizes (typically less than 3mm). They offer high separation accuracy and are dust-free, making them the preferred choice for most metal ore processing plants. Dry magnetic separators separate ore in air and are suitable for water-scarce areas or applications where the moisture content of the raw material is critical (such as quartz sand and feldspar). Our engineers can recommend the most suitable type based on your ore properties and local conditions.

Q2: Is a higher magnetic field strength always better for a magnetic separator?

A: Not necessarily. The magnetic field strength needs to match the specific magnetic susceptibility of the target mineral. Excessive strength not only increases energy consumption but may also adsorb more intergrowths or impurities, reducing concentrate grade. Our equipment offers adjustable magnetic field strength options to ensure the optimal balance between efficient recovery and product grade.

Q3: What is the warranty period for your equipment? Do you provide installation guidance?

A: We offer at least a one-year warranty on all mining magnetic separators. In addition, we provide detailed installation drawings, operation manuals, and video tutorials. If required by the customer, we can send experienced engineers to the site for installation, commissioning, and technical training to ensure stable operation of the equipment.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!