Configuration Scheme for a 150 t/h Cone Crusher Production Line

Located in the heart of the Middle East, Palestine's demand for crushers primarily stems from infrastructure gaps created by post-war reconstruction and the need for natural resource development. Market research indicates that the Palestinian crusher market is characterized by high demand and low supply, with over 90% of equipment relying on imports. The local industrial base is weak, with domestic manufacturing primarily focused on low-end processing, and high-end equipment almost entirely dependent on imports. This presents a significant market opportunity for equipment suppliers.

Configuration Scheme for a 150-ton/hour Cone Crusher Production Line

Core Equipment Selection

| Features/Parameters | Description/Specifications |

| Equipment Model: HPT300 | Multi-cylinder Hydraulic Cone Crusher |

| Recommended Capacity | 150 tons/hour |

| Feed Size | 230mm |

| Applicable Materials | Iron Ore |

| Maximum Feed Size | ≤150mm |

| Core Technology | Layered Crushing Principle |

| Core System | Hydraulic System |

| Core Advantages | Precise adjustment of the discharge port ensures uniform and stable output particle size |

Production Line Process Flow

Okay, based on your instructions, we have added jaw crusher to the original process flow description, optimizing it into a more complete and practical two-stage closed-loop process flow diagram, clearly presented in tabular form.

Process Flow of a 150-ton/hour Cone Crusher Production Line (Two-stage, Closed-Circuit)

| Process Steps | Core Equipment | Process Description | Output Status/Destination |

| 1. Feeding | Vibrating Feeder | Raw materials (particle size ≤ 500mm) are uniformly and continuously fed into the jaw crusher from the hopper via the vibrating feeder. | This achieves uniform and controllable feeding, protecting downstream equipment. |

| 2. Primary Crushing (Coarse Crushing) | Jaw Crusher | The jaw crusher performs primary crushing of the raw materials, crushing them to a particle size ≤ 150mm to meet the feeding requirements of the cone crusher. | It produces intermediate products ≤ 150mm, which enter the next stage of crushing. |

| 3. Medium and Fine Crushing | Cone Crusher (HPT300) | Stone from the jaw crusher is fed into the cone crusher for efficient medium and fine crushing. | It produces a mixture of materials of different particle sizes, which enters the screening process. |

| 4. Screening | Vibrating Screen | All material from the cone crusher is fed into a vibrating screen for grading and screening. | The material is pided into finished product and return material according to the preset screen size (e.g., 10mm). |

| 5. Finished Product Collection | Finished Product Stockpile/Conveyor | Undersize material, i.e., material smaller than 10mm, meets the finished product particle size requirements and is conveyed to the finished product stockpile. | Final product, process ends. |

| 6. Closed-Loop Circulation | Conveyor | Oversize material, i.e., material larger than 10mm, is returned to the cone crusher for further crushing via a return conveyor. | This forms a closed-loop circulation, ensuring that all material is crushed to the qualified particle size. |

Summary of Process Advantages: This jaw crusher + cone crusher + screening closed-loop configuration, compared to more complex multi-stage crushing, greatly simplifies the process flow while ensuring product particle size. It reduces equipment investment and plant footprint, while ensuring system efficiency and stability through closed-loop circulation, making it ideal for medium-sized production lines with an hourly output of 150 tons.

Configuration Scheme for a 150 t/h Cone Crusher Production Line

Equipment Technical Advantages

High Efficiency and Energy Saving Performance

The HPT300 multi-cylinder hydraulic cone crusher adopts the principle of layered crushing. Material is distributed in multiple layers within the crushing chamber, subjected not only to the extrusion force of the moving and fixed cones but also to inter-material compression and collision. This increases crushing efficiency by 5%-15% compared to traditional spring cone crushers. Under the same production capacity, power consumption can be reduced by approximately 30%, with an annual operating time exceeding 7200 hours and equipment utilization exceeding 90%.

Excellent Product Particle Shape

The equipment employs an optimized crushing chamber design, resulting in iron ore particles that are predominantly cubic with low needle-like and flaky content. This is beneficial for subsequent grinding processes and significantly improves mill efficiency. The product has uniform particle size, with 60%-70% of particles in the 0-5mm range, fully meeting the production requirements for high-quality construction aggregates.

Intelligent Control System

The equipment is equipped with an intelligent control system that can monitor the crusher's operating status in real time, including key parameters such as spindle position, lubricating oil temperature, and pressure. The hydraulic system has an over-iron protection function; when uncrushable materials enter the crushing chamber, the hydraulic cylinder automatically depressurizes to protect the equipment from damage. Operation is simple; only 1-2 operators are needed to monitor and adjust the entire production line.

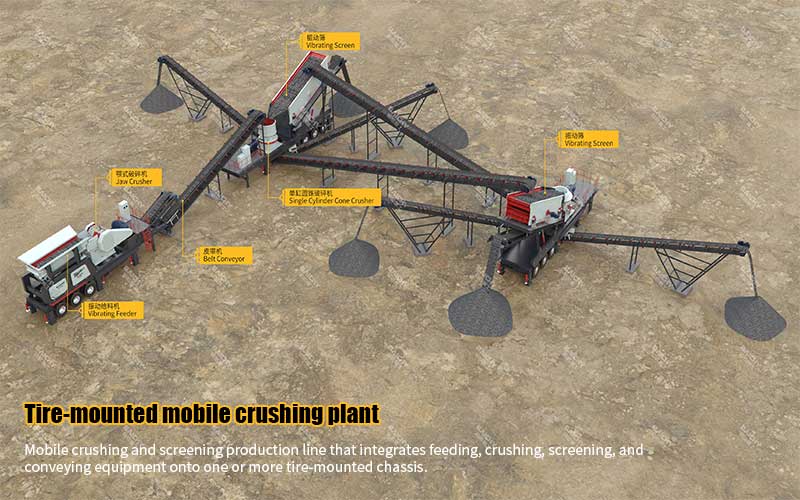

Mobile jaw and cone crushing palnt

Application Case Studies

Case 1: Mexican Iron Ore Beneficiation Plant

A medium-sized iron ore beneficiation plant in Mexico originally used a traditional two-stage crushing process, which involved multiple pieces of equipment, a complex process, and high energy consumption. After being upgraded to a single HP300 multi-cylinder hydraulic cone crusher, the output not only met the design requirement of 150 tons/hour, but also reduced power consumption by 35%, saving over 1 million yuan in electricity costs annually. Simultaneously, due to improved product particle shape, subsequent grinding efficiency increased by 15%, resulting in significant overall economic benefits.

Case 2: Southeast Asian Sand and Gravel Aggregate Production Line

In a sand and gravel aggregate production line project in Southeast Asia, an HP300 single-cylinder cone crusher + mobile screening station configuration was adopted to achieve automated production. The finished product boasts excellent particle shape, with a reasonable proportion of 0-5mm manufactured sand, fully meeting the demands of the high-end construction market and earning a strong reputation in the local market.

Adaptability to the Palestinian Market

Localized Service Advantages

Tailored to the specific needs of the Palestinian market, we offer flexible payment options and rapid response capabilities. The equipment features a modular design, with long replacement cycles for core wear parts such as liners and grinding mill walls, simplifying maintenance. We also provide remote technical support, enabling remote equipment monitoring via IoT technology to predict the lifespan of wear parts and reduce downtime.

Environmental Performance

The equipment employs a fully enclosed structure, working in conjunction with a dust removal system to effectively control dust pollution during production. Operating noise is below 85 decibels, fully complying with environmental requirements. This is a significant competitive advantage in the increasingly stringent environmental regulations of the Palestinian region.

Frequently Asked Questions (FAQ)

Q1: How can the equipment ensure normal operation in the Palestinian region with its unstable power supply?

A: The equipment is equipped with an intelligent control system that adapts to grid fluctuations. Furthermore, we can provide a variable frequency speed control system to reduce peak energy consumption. For areas with particularly unstable power supply, a diesel-powered configuration is available as an option to ensure stable equipment operation.

Q2: What are the service life and replacement cycle of the equipment's vulnerable parts?

A: The equipment uses high-manganese steel (Mn13) liners with a heat-treated finish, achieving a hardness ≥55HRC, extending their service life by 20% compared to ordinary liners. Under normal operating conditions, vulnerable parts can last 3-5 years, resulting in significantly lower maintenance costs compared to traditional equipment.

Q3: How do you address equipment maintenance and spare parts supply issues in the Palestinian region?

A: We provide a global spare parts supply network to ensure timely replacement of vulnerable parts. Furthermore, the equipment employs a modular design, allowing for core component replacement without disassembling the entire unit, significantly reducing downtime. We also offer localized training to help customers master equipment maintenance skills.

Recommended Configuration

Based on the actual needs of the Palestinian market, we recommend the following configuration:

• Core Equipment: One HP300 multi-cylinder hydraulic cone crusher

• Auxiliary Equipment: Vibrating feeder, circular vibrating screen, and several conveyors

• Control System: Intelligent control system (including remote monitoring function)

• Environmental Protection Configuration: Dust removal system, noise reduction device

• Production Capacity: 150 tons of iron ore or sand and gravel aggregate per hour

This configuration offers moderate total investment, low operating costs, and easy maintenance, making it particularly suitable for small and medium-sized mines and sand and gravel plants in the Palestinian region.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!