In the modern mineral processing and powder industry, vertical roller mills (also known as vertical mills or vertical grinding mills) have become the preferred equipment for grinding materials such as ores, slag, and cement raw materials. This highly efficient vertical mineral grinding equipment, with its unique design and superior performance, is redefining the efficiency standard for industrial grinding.

1. Core Working Principle of the Vertical Roller Mill: Innovative Material-Bed Grinding Technology

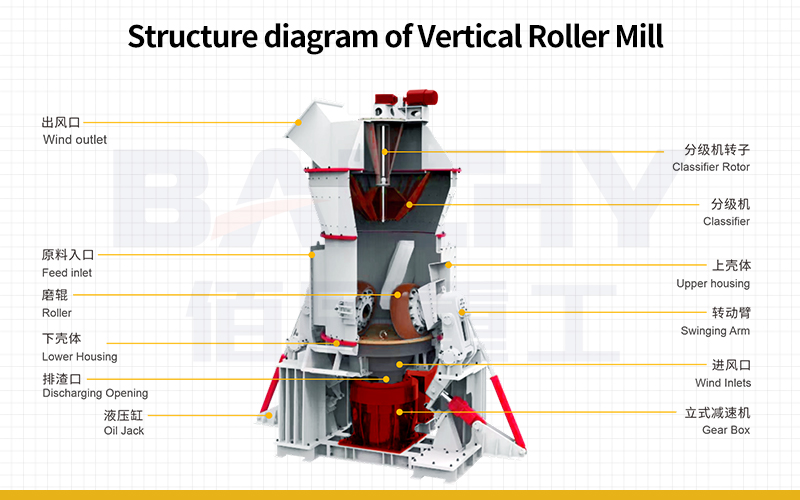

The vertical roller mill utilizes the advanced "material-bed grinding" principle, using multiple grinding rollers to crush bulk or granular mineral materials into a powder of the desired fineness. This design integrates five major functions: crushing, grinding, drying, grading, and conveying, revolutionizing the complex process of traditional grinding.

Detailed Process Flow:

The material enters the center of the grinding disc through a closed feeding system and is evenly distributed toward the edges under the action of centrifugal force. The grinding rollers, mounted on a pressure frame, work under the action of a hydraulic system to uniformly crush the material. The crushed material is carried by the system's airflow to the top dynamic separator for precise sorting. Qualified fine powder flows with the airflow into the collector to become the finished product, while coarse powder falls back to the grinding disc for re-grinding. The entire process is fully automated, ensuring stable and efficient operation.

II. Six Core Structural Advantages of Vertical Roller Mills

1. Vertical Design: Its vertical layout reduces floor space by approximately 50% compared to traditional ball mills, significantly reducing capital investment.

2. High-Efficiency Grinding System: The curved design of the grinding rollers and grinding discs increases grinding efficiency by over 30%.

3. Hydraulic Pressure Device: Providing constant grinding pressure, automatically compensating for roller wear, and ensuring consistent product quality.

4. Dynamic Separation Technology: A high-efficiency powder concentrator with variable frequency speed control allows for easy adjustment of product fineness between 80 and 600 mesh.

5. Integrated Drying Function: Hot air can be introduced for simultaneous grinding and drying, handling materials with a moisture content of up to 15%.

6. Low-Wear Design: Key components are made of wear-resistant alloys, extending service life by 2-3 times.

III. Performance Comparison of Vertical Roller Mills and Traditional Ball Mills

| Performance Specifications | Vertical Roller Mill | Traditional Ball Mill |

| Energy Consumption | Reduced by 30%-50% | Benchmark |

| Footprint | Reduced by 40%-60% | Benchmark |

| Product Fineness Adjustment | Fast and flexible, online adjustment | Difficult, requires downtime |

| Noise Level | <85dB | >100dB |

| System Flow | Simple, integrated design | Complex, requires multiple devices |

IV. Wide Range of Applications for Vertical Roller Mills

• Cement Industry: Raw meal preparation, cement clinker grinding, and slag micro-powder production

• Non-metallic Mineral Processing: Preparation of ultrafine powders such as limestone, calcite, barite, talc, quartz, and bentonite

• Metallurgical Industry: Resource Utilization of Solid Waste Such as Metallurgical Slag, Ferronickel Slag, and Steel Slag

• Power and Environmental Protection: Pulverizing limestone for power plant desulfurization and preparing flue gas desulfurizers

• New Building Materials: Production of mineral admixtures, composite powders, and specialty cements

V. Scientific Selection Guide: How to Choose the Right Vertical Grinding Mill

Selecting a Vertical Roller Mill requires considering several key factors:

1. Material Property Analysis: This includes material hardness (Mohs hardness), feed particle size, moisture content, and chemical composition.

2. Capacity Requirements Assessment: Equipment specifications are determined based on the scale of the production line, ranging from a few tons to hundreds of tons per hour.

3. Clear Product Requirements: Specific requirements for finished product fineness range, particle size distribution, and product shape.

4. System Planning: Whether integrated additional functions such as drying, dust removal, and automated control are required.

5. Balancing the Investment Budget: Comprehensively consider equipment price, installation costs, operating and maintenance expenses, and payback period.

VI. Key Points for Vertical Roller Mill Operation and Maintenance

Daily Operating Procedures:

• Thoroughly check all components for tightness before startup.

• Start the machine in strict accordance with the operating procedures.

• During operation, closely monitor key parameters such as main motor current, grinding pressure, and vibration.

• Regularly check the wear of the grinding rollers and grinding disc liners, and adjust the roller gap promptly.

Maintenance Plan:

• Check the lubrication system oil level and quality every shift.

• Clean the hydraulic system filter weekly.

• Check the condition of the transmission and bearings monthly.

• Replace wear parts according to the service schedule to avoid unplanned downtime.

As a core technology in modern mineral processing, vertical roller mills are gaining widespread adoption worldwide for their superior grinding efficiency, flexible adjustment capabilities, and significant energy savings. For companies planning to build or upgrade a new grinding line, selecting the right vertical grinding equipment is a key decision to enhance competitiveness.

Stay tuned for more industry technical news! If you need a specific plan or price guide for a vertical roller mill, please contact our professional technical team to get a personalized solution.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)

Further reading:

How To Choose A Suitable Industrial Grinding Mill?

Which Is Better Cement Vertical Roller Mill Or Ball Mill?

What Are the Differences between Dry and Wet Type Ball Mill?