How to choose a suitable industrial grinding mill? Comprehensive purchase guide and practical suggestions

Industrial grinding mills are indispensable key equipment in industries such as mining, building materials, chemicals, and metallurgy. A suitable grinding mill can greatly improve production efficiency and reduce energy consumption costs. However, many buyers are often confused by the wide variety of grinding mill types and brands on the market. This article will provide you with a comprehensive guide to purchasing industrial grinding mills, from type comparison to key parameter analysis, to help you make wise investment decisions.

Before choosing an industrial grinding mill, you must first clarify the four core requirements: material properties (including hardness, initial particle size, moisture content, viscosity and special properties), output requirements (current processing volume and future expansion needs), finished product fineness standards (target particle size range and distribution) and production environment restrictions (space size, power conditions, environmental protection requirements, etc.). These basic elements will directly affect the selection of grinding mill types and equipment configuration plans.

Comprehensive comparison of mainstream industrial grinding mill performance

| Type |

Fineness range (mesh) |

Applicable hardness |

Energy consumption |

level|Output range |

Initial investment |

| Raymond mill |

80-325 |

Medium-low |

Low |

Medium| |

Low |

| High-pressure suspension roller mill |

80-1000 |

Medium |

Medium |

Medium-high |

Medium |

| Ball mill |

200-3000 |

High |

High |

High |

Medium-high |

| Vertical mill |

200-1500 |

High |

Medium |

High |

High |

| Air flow mill |

500-10000 |

Medium |

Extremely high |

Low |

Extremely high |

8 key parameters for selecting industrial grinding mills

In addition to the type of grinding mill, the following key parameters directly affect equipment performance and return on investment:

• Grinding fineness: Select according to the requirements of the final product, pay attention to indicators such as "80% pass rate"

• Production capacity: Consider peak demand and average demand, and leave a 10-20% margin

• Motor power: directly affects energy consumption cost, compare energy consumption per unit output

• Wear-resistant parts life: replacement cycle and cost of wearing parts such as grinding rollers and grinding rings

• Automation level: PLC control system of modern grinding mills can greatly improve stability

• Dust control: dust removal system that meets local environmental protection requirements

• Noise level: especially in occasions with strict requirements on factory environment

• Maintenance convenience: details such as access door design and lubrication system

5 common misunderstandings in purchasing industrial grinding mills

During the procurement process, avoiding the following common mistakes can save a lot of costs:

• Excessive pursuit of low prices: low-priced equipment often means higher operating costs and shorter life

• Ignoring operating costs: long-term costs such as power consumption and replacement of wearing parts may far exceed the price of the equipment

• Improper capacity matching: too large will cause waste, too small will affect production

• Ignoring installation requirements: preliminary preparations such as infrastructure and power configuration

• Disregarding after-sales service: Reliable after-sales service can significantly reduce downtime losses

Main points for industrial grinding mill maintenance

Proper maintenance can extend the life of the equipment by more than 30%:

• Daily inspection: bearing temperature, abnormal sound, etc.

• Regular lubrication: Use specified lubricants according to the instructions

• Replacement of wear parts: Timely replacement of grinding rollers, grinding rings and other wearing parts

• Cleaning and maintenance: Especially dust removal systems and ventilation ducts

• Seasonal maintenance: Such as winter antifreeze measures

Future development trend of industrial grinding mills

Understanding industry trends helps to make more forward-looking purchasing decisions:

• Intelligence: Internet of Things technology realizes remote monitoring and predictive maintenance

• Energy saving and environmental protection: New energy-saving design and efficient dust removal system

• Multifunctionality: One device can handle a variety of materials

• Ultrafine grinding: Development of nano-powder processing technology

• Customized service: Design special equipment according to customer's specific needs

Through the systematic selection framework provided in this article, I believe you can find the industrial grinding mill that best suits your production needs, laying a solid foundation for improving the production efficiency and quality of the enterprise. If you need further consultation or obtain a quotation for a specific model, please contact our professional team.

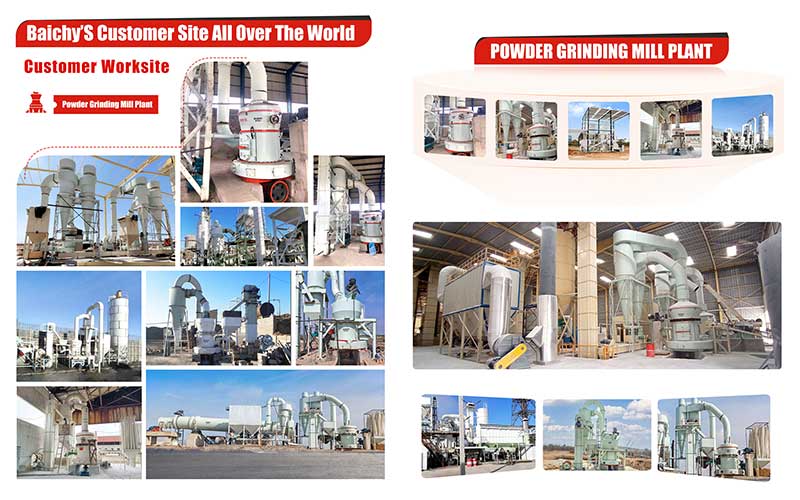

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Further reading: