Cement vertical roller mill vs. ball mill: Which one is more suitable for your production needs?

In the cement production process, the choice of grinding equipment directly affects production efficiency, energy consumption cost and product quality. At present, vertical roller mill (vertical mill) and ball mill are two mainstream cement grinding equipment, but they have significant differences in performance, energy consumption, maintenance and applicable scenarios. This article will comprehensively compare the advantages and disadvantages of these two equipment to help you make the best choice.

1. Equipment Overview

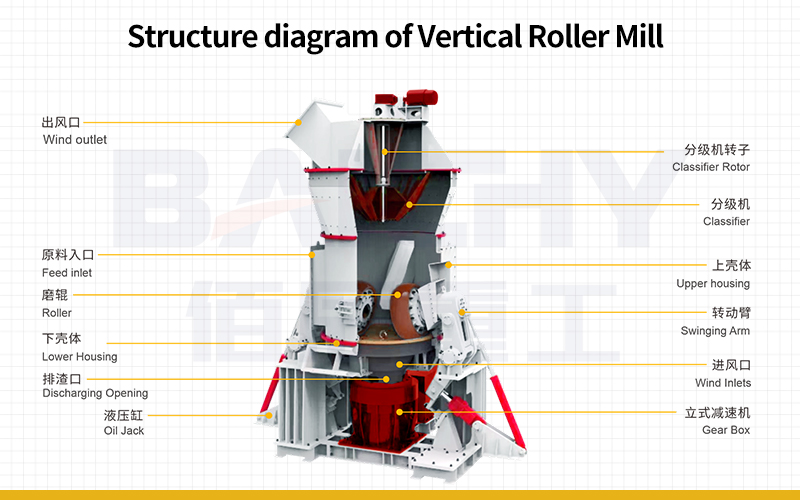

1.1 Vertical Roller Mill (Vertical Mill)

The vertical roller mill adopts the working principle of roller pressing + grinding. The material is crushed between the grinding disc and the grinding roller, and the required fineness is achieved through airflow sorting.

Main features:

• High efficiency and energy saving, energy consumption is 30%-50% lower than that of ball mill

• Small footprint, suitable for factories with limited space

• Grinding fineness can be precisely controlled, suitable for high-grade cement production

• Low noise, good dust control

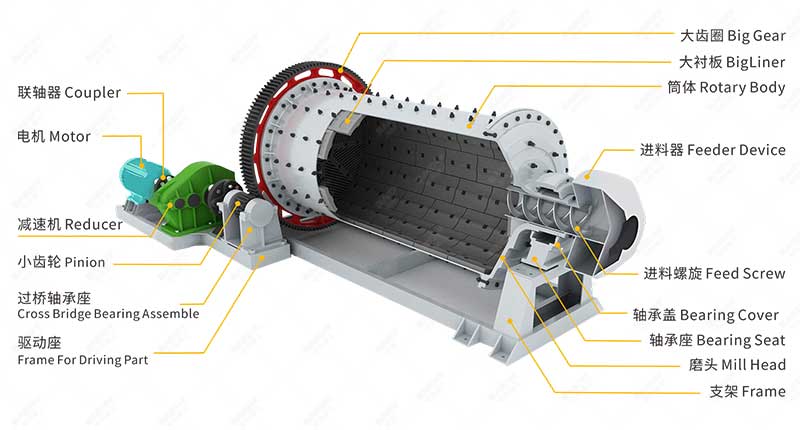

1.2 Ball mill

Ball mill crushes materials through the impact + grinding of steel balls and materials, suitable for materials of various hardness.

Main features:

• Strong adaptability, can handle raw materials of different hardness

• Simple equipment structure, low maintenance cost

• Stable operation, suitable for long-term continuous production

• Relatively low investment cost

2. Performance comparison

| Comparison items | |Vertical roller mill | Ball mill |

| Energy consumption | Low (30%-50% energy saving than ball mill) | Higher |

| Grinding fineness | Can be precisely controlled, suitable for high-grade cement | Wide fineness adjustment range, but slightly lower control accuracy |

| Output | High single-machine capacity, suitable for large-scale production | Stable output, but high unit energy consumption |

| Occupancy area | Small, suitable for compact factories | Large, requires more space |

| Noise | Low (about 75-85 decibels) | Higher (85-95 decibels) |

| Dust control | Good sealing, less dust | More dust, need additional dust removal equipment |

3. Cost analysis

3.1 Initial investment

Vertical mill: The initial investment is high, but the long-term energy-saving benefits are significant.

Ball mill: The equipment price is low, but the operating energy consumption is high.

3.2 Operation and maintenance costs

Vertical mill: The replacement cost of wearing parts (such as grinding rollers and grinding discs) is high, but the maintenance cycle is long.

Ball mill: The steel balls and liners wear quickly, but the replacement cost is low.

3.3 Applicable scenarios

Vertical mill is more suitable for:

• High-volume, high-grade cement production

• Enterprises with high energy-saving and consumption-reduction requirements

• Factories with limited space

Ball mill is more suitable for:

• Small and medium-sized cement plants or situations where the hardness of raw materials varies greatly

• Enterprises with limited budgets and pursuing stable operation

4. Environmental protection and future trends

4.1 Environmental performance

Vertical mill: Less dust emission, low noise, in line with modern environmental protection requirements.

Ball mill: It needs to be equipped with high-efficiency dust removal equipment, otherwise the dust pollution is serious.

4.2 Industry Trends

As energy-saving and environmental protection policies become stricter, the proportion of vertical mills in the cement industry has increased year by year. In particular, large cement companies prefer to adopt a vertical mill + ball mill combined grinding system to balance efficiency and cost.

5. Conclusion: How to choose?

| Selection criteria | Recommended equipment |

| Pursue high output and low energy consumption | Vertical roller mill |

| Limited budget, stable operation required | Ball mill |

| Produce high-grade cement | Vertical roller mill |

| Raw material hardness varies greatly | Ball mill |

| Strict environmental protection requirements | Vertical roller mill |

Final recommendation:

Large cement plants, new production lines → Prefer vertical mills

Small and medium-sized cement plants, renovation projects → Consider ball mills or combined grinding systems