More Than Just Crushing, a Revolution in Efficiency: An In-Depth Analysis of the Industrial Value and Application Wisdom of the 250x1200 Jaw Crusher

In industries such as mining, construction, and metallurgy, the choice of crushing equipment is directly related to production efficiency and cost control. Among the many jaw crusher models, the 250x1200 jaw crusher (PEX250×1200) has become a highly favored machine for medium and fine crushing operations due to its unique positioning and performance. However, its value goes far beyond "crushing"—it embodies a refined production approach, a wisdom that pursues efficiency and adaptability in the ruggedness of heavy industry.

1. Redefining "Medium Particle Size": Why 250x1200?

As the model name suggests, the 250x1200 jaw crusher has a feed opening size of 250mm x 1200mm, a maximum feed size of approximately 210mm, and a flexibly adjustable discharge size between 18 and 60mm. This parameter setting is no accident; it precisely addresses the needs of medium and fine crushing applications:

• It fills the gap between coarse crushing (such as PE series jaw crushers) and ultra-fine crushing (such as cone crushers and sand making machines), making it particularly suitable for use as a secondary crushing device.

• Its processing capacity ranges from approximately 20-60 tons/hour (some optimized models can reach 105 t/h), perfectly matching the production needs of small and medium-sized production lines, avoiding resource waste or capacity bottlenecks.

Unlike coarse jaw crushers, which prioritize "large intake and powerful crushing," the 250x1200 jaw crusher prioritizes a balance between output quality and energy consumption. For example, in construction aggregate production, it can directly produce crushed stone that meets specifications, eliminating subsequent screening and re-crushing steps, thereby reducing overall energy consumption.

II. Structural Innovation: Small yet Powerful, Simple yet Efficient

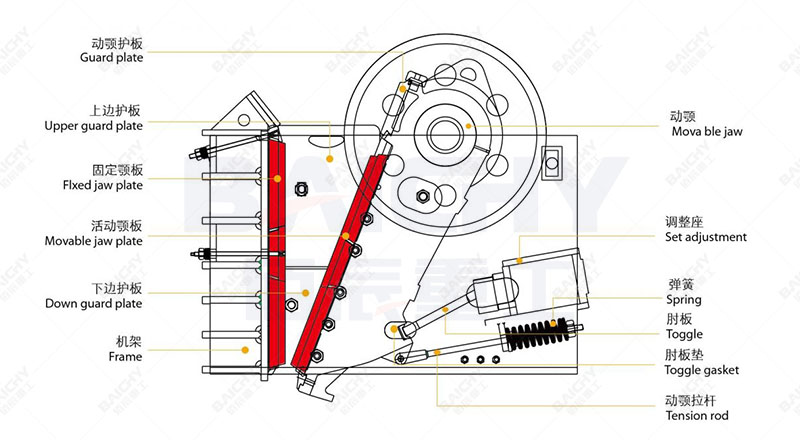

The 250x1200 jaw crusher is generally classified as the PEX series (fine crushing type). Its structural design embodies the concept of "precision crushing":

1. Dynamic Jaw Plate Optimization Trajectory: Through precise calculation of the toggle plate and linkage mechanism, the movable jaw's motion trajectory not only achieves efficient crushing, but also reduces unnecessary friction and extends the life of wear parts.

2. Hydraulic Adjustment Device (select high-end models): This allows for quick adjustment of the discharge opening without manual downtime, significantly enhancing production flexibility and continuity.

3. Compact Frame Design: The machine's moderate weight (approximately 6-8 tons) facilitates transportation and installation, making it particularly suitable for projects with limited space or frequent relocation.

These features significantly surpass traditional primary crushing equipment in terms of reliability and maintenance costs, making it particularly suitable for small and medium-sized enterprises or distributed operations.

III. Application Scenarios: Beyond Conventional Adaptability

In addition to common applications in mining and construction, the 250x1200 jaw crusher demonstrates unique value in several specialized applications:

• Urban construction waste recycling: Its moderate feed size allows it to effectively process recycled resources such as concrete blocks and bricks, while its output size meets recycled aggregate standards;

• Pre-crushing in small and medium-sized ore processing plants: In the pre-processing of metal ore, it can replace some cone crushers for secondary crushing, reducing equipment investment and operating costs;

• Core unit for integrated mobile crushing plants: Due to its compact structure and balanced performance, it is often integrated into mobile crushing equipment, making it suitable for a variety of on-site operations.

IV. Selection Decision: Why might it not be suitable for everyone?

While the 250x1200 jaw crusher offers significant advantages, a rational assessment is required when choosing one:

• Irreplaceable coarse crushing: If the raw material size exceeds 300mm or the processing capacity required is extremely high (such as primary crushing in large mines), a PE series coarse jaw crusher or gyratory crusher is still required as a pre-processing device;

• Material property limitations: For materials with high hardness (such as granite and basalt) or high viscosity, a pre-screening or special jaw plates must be used to prevent rapid wear;

• Capacity ceiling: If the project plans to expand production later, it is necessary to consider equipment upgrade paths in advance or choose a modular layout to reserve space.

V. Future Evolution: Intelligent and Green

As the Industry 4.0 trend deepens, the 250x1200 jaw crusher continues to evolve:

• Intelligent Sensing and Remote Monitoring: Real-time monitoring of bearing temperature, vibration data, and jaw plate wear allows for predictive maintenance cycles, avoiding unplanned downtime.

• Energy-saving motor and variable frequency drive: Automatically adjusts speed based on changes in material hardness, achieving "soft crushing" and dynamically optimizing energy consumption.

• Material Innovation: The use of composite alloy jaw plates increases lifespan by over 30%, reducing replacement frequency and the environmental impact of discarded parts.

Choosing the 250x1200 jaw crusher represents a shift in production philosophy.

Traditionally, crushing equipment is often viewed as synonymous with "powerful and extensive." However, the introduction of the 250x1200 jaw crusher proves that true efficiency lies not in maximum power or size, but in precisely matching production needs and resource inputs. While it may not offer the highest output, it embodies the ideal balance of cost-effectiveness and efficiency for many small and medium-sized projects. When choosing a crushing machine, you might as well ask yourself: Do we need more power or smarter power? The answer given by the 250x1200 jaw crusher is clearly the latter.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)