The design scheme of the 100-150 t/h stone crushing plant in Mexico can be planned and constructed with reference to the following points:

Overview of the 100-150 t/h stone crushing plant in Mexico

This project aims to establish a 100-150 t/h stone crushing plant in Mexico to meet the needs of the local stone processing and construction industries. By introducing advanced stone crushing equipment and production line configuration, the production goals of high efficiency, low cost and environmental protection are achieved.

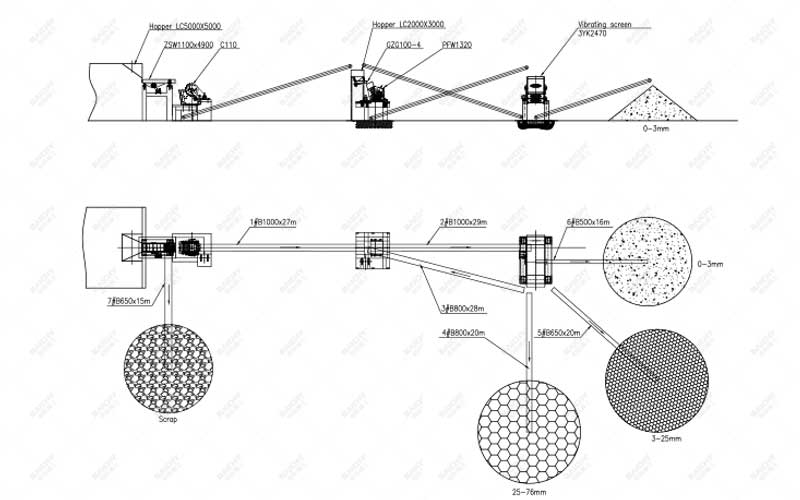

Production line configuration of 100-150 t/h stone crushing plant in Mexico

1. Crushing equipment: According to the production requirements, one or more crushers with high efficiency and high crushing ratio, such as jaw crusher, cone crusher, etc., can be selected. The model and specifications of the crusher should be adjusted according to the hardness and particle size of the raw materials to ensure the crushing effect and output.

2. Screening equipment: During the crushing process, screening equipment is required to screen the crushed stone to meet the needs of different particle sizes. Vibrating screens, drum screens and other equipment can be selected for screening.

3. Conveying equipment: In order to transport raw materials, crushed stones and screened finished products, corresponding conveying equipment such as belt conveyors, bucket elevators, etc. is required.

Production process of a 100-150 t/h stone crushing plant in Mexico

• Raw material preparation: The stones to be crushed are sent to the raw material bin through a loader or other equipment.

• Primary crushing: The raw materials are sent to the jaw crusher through a vibrating feeder for primary crushing, and the crushed stones are sent to the next process through a belt conveyor.

• Secondary crushing (optional): According to demand, the stones after primary crushing can be sent to a cone crusher or other types of crushers for secondary crushing to achieve finer particle size requirements.

• Screening: The crushed stones are screened through screening equipment to obtain finished products of different particle sizes.

• Finished product transportation: The screened finished products are sent to the finished product bin or loaded through a belt conveyor or other conveying equipment.

• High efficiency: High-efficiency production is achieved through reasonable equipment configuration and optimized production processes.

• Environmental protection and energy saving: Select low-noise and low-emission equipment, and configure dust removal and noise reduction facilities to ensure environmental protection and energy saving in the production process.

• High degree of automation: The PLC control system is used to realize automatic control of the production process, reduce manual operations, and improve production efficiency and safety.

The design plan of the 100-150 t/h stone crushing plant in Mexico should comprehensively consider factors such as raw material characteristics, output requirements, and environmental protection requirements, and select appropriate equipment and configuration to achieve high-efficiency, low-cost and environmentally friendly production goals. At the same time, attention should be paid to the maintenance and maintenance of the equipment to ensure the stable operation of the production line and extend the service life of the equipment.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)