Spiral Chutes - Baichy Conveyors - Conveying Systems

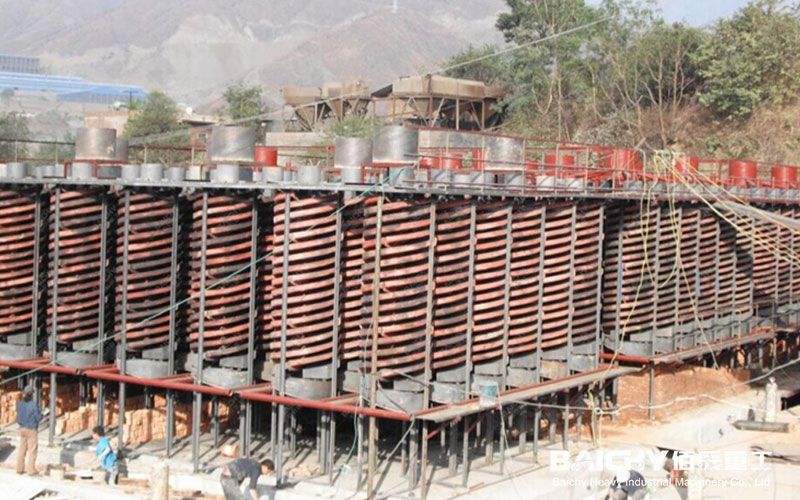

As a mining equipment manufacturer with 20 years of experience, we understand the critical importance of selecting efficient, reliable, and economical equipment in the ore beneficiation process. Among numerous gravity separation equipment, the spiral chute has consistently held an indispensable position due to its unique structure and working principle. This article will take you on an in-depth exploration of how this classic equipment continues to create value for the modern mining industry.

| Key Words | Spiral Chutes - Baichy Conveyors |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. In-depth Analysis of the Topic: What is a Spiral Chute?

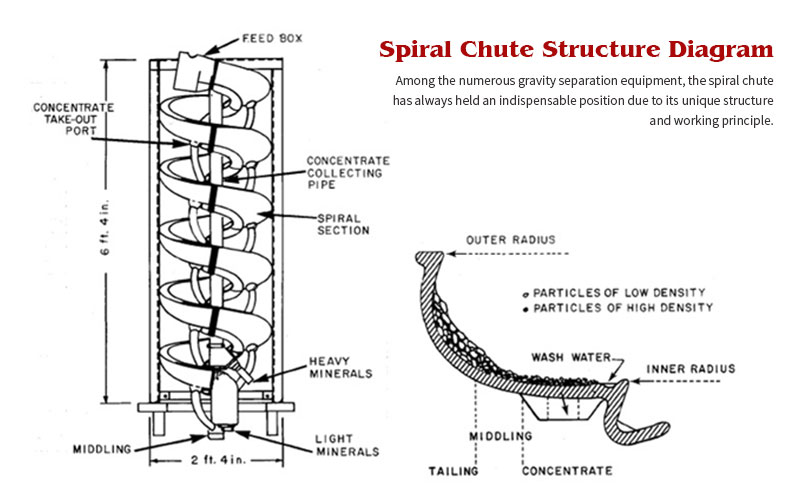

A spiral chute is a static gravity separation device that utilizes the combined effects of gravity, centrifugal force, hydrodynamic force, and friction to separate mineral particles based on differences in density and particle size. It requires no external power, relying solely on the potential energy and fluidity of the ore slurry to complete the separation process, making it a model of energy conservation and cost reduction.

II. Equipment Overview and Working Principle

1. Structural Components

A typical spiral chute mainly consists of a feeder, spiral chute body, splitter, chute support, and receiving trough. Its core component – the spiral chute body – is usually made of fiberglass (glass fiber reinforced plastic), lined with a wear-resistant layer, and features light weight, high strength, corrosion resistance, and long service life.

2. Brief Description of the Working Process

After the ore slurry is evenly distributed at the top of the spiral chute by the feeder, it flows downwards along the spiral chute under the action of gravity. During this process, denser mineral particles settle faster and move closer to the inner side of the chute; less dense particles are pushed towards the outer edge of the chute by the water flow. By setting a splitter at the end of the chute, minerals of different densities can be separated into concentrate, middlings, and tailings, achieving effective separation.

Spiral chute structure diagram

III. Core Advantages of the Spiral Chute

After 20 years of technological accumulation and on-site application optimization, modern spiral chutes demonstrate the following significant advantages:

• High efficiency and energy saving: Completely relies on gravity flow, requiring no power, resulting in extremely low operating costs.

• Simple structure and easy maintenance: The equipment has no moving parts, resulting in a low failure rate and simple operation and maintenance.

• Large processing capacity and good separation effect: A single unit can process a large amount of ore slurry, and it has high separation efficiency and a high enrichment ratio for specific particle sizes (especially 0.03-1mm). • Strong adaptability: Suitable for the separation of various metallic and non-metallic minerals such as iron ore, tungsten ore, tin ore, tantalum-niobium ore, and beach sand deposits, especially suitable for processing low-grade ores.

• Environmentally friendly: The separation process does not require the addition of chemical reagents, making it environmentally friendly.

IV. Application Cases: Witnessing Successful Practices

In a beach sand ilmenite beneficiation project, the client originally used traditional processes, resulting in low recovery rates and high energy consumption. We designed and provided a roughing-scavenging process consisting of five-layer fiberglass spiral chutes. After equipment installation:

• Processing capacity: The raw ore processing capacity reached 80 tons per hour.

• Separation indicators: The grade of titanium concentrate increased from 8% in the feed to over 42%, with a recovery rate exceeding 85%.

• Economic benefits: Electricity costs alone saved over 300,000 RMB annually, with a short investment payback period and extremely high customer satisfaction.

V. Recommended Related Equipment: Building a Complete Conveying and Separation System

Spiral chutes often serve as the core of the separation process and need to work in conjunction with upstream and downstream equipment. Baichy not only provides high-quality spiral chutes but also offers complete system solutions:

• Feeding system: We recommend using our Baichy plate feeders or vibrating feeders to ensure uniform and stable feeding to the spiral chutes.

• Conveying system: Before and after separation, Baichy belt conveyors can be used for material transfer. This system operates smoothly, has a long conveying distance, and is an ideal choice for connecting various process stages.

• Dewatering equipment: The separated concentrate can be dewatered using high-efficiency thickeners or dewatering screens for easy transportation and storage.

VI. Frequently Asked Questions (FAQ)

Q1: What is the most suitable particle size range for spiral chutes?

A1: The effective separation particle size range of spiral chutes is usually between 0.03-1 mm. For materials that are too coarse (>2mm) or too fine (<0.02mm, such as mud), the separation effect will decrease, and it is necessary to consider working in conjunction with screening and classification equipment.

Q2: How to adjust the separation effect of the spiral chute?

A2: This is mainly achieved by adjusting the feed concentration, feed rate, and the position of the splitter. The feed concentration is generally controlled at 30%-40%. By adjusting the height and angle of the splitter, the yield and grade of concentrate, middlings, and tailings can be changed. The optimal position needs to be determined based on the ore properties and on-site testing.

Q3: What are the differences between a spiral chute and a jigging machine?

A3: Both are gravity separation equipment, but their principles are different. Jigging machines use pulsed water flow to loosen and stratify the bed, making them more suitable for processing coarse and medium-grained ores, with a larger upper limit for particle size. However, the equipment is relatively complex and consumes more energy. Spiral chutes are suitable for medium and fine-grained materials, are more energy-efficient, have a larger processing capacity, and occupy less space. The choice should be made based on the ore particle size, density difference, and investment budget.

As a classic gravity separation equipment that has stood the test of time, the spiral chute, with its excellent energy-saving characteristics, stable separation performance, and low operating costs, still maintains its vitality in modern mineral processing plants, especially in processes handling medium and fine-grained disseminated ores and beach sands. Choosing an experienced manufacturer is crucial to ensuring equipment performance and application effectiveness.

Further reading:

How To Reduce The Energy Consumption Of Ball Mill? 5 Practical Energy-Saving Tips

Iron Ore Beneficiation Process: Magnetic Separation/Flotation/Gravity Separation