Ball mills are key equipment in industries such as mining, cement, and metallurgy, but their high energy consumption has always been a pain point in the operating costs of enterprises. How to reduce the energy consumption of ball mills without affecting production efficiency? This article will share 5 practical energy-saving tips to help you optimize equipment operation and save electricity costs!

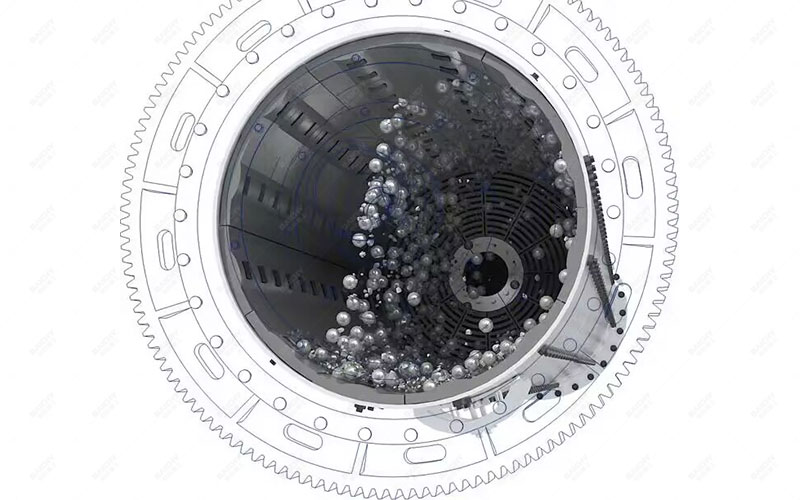

1. Optimize the ratio of grinding media (steel balls)

Problem: Unreasonable size and ratio of steel balls will lead to low grinding efficiency and increased energy consumption.

Solution:

• Adjust the diameter of steel balls according to the hardness of the material (usually 20-100mm).

• Control the filling rate at 30%-35% to avoid too much or too little.

• Check the wear of steel balls regularly and replenish or replace them in time.

• Energy-saving effect: Reasonable ratio can reduce invalid collisions, improve grinding efficiency, and reduce energy consumption by 10%-15%.

2. Control material particle size and moisture

Problem: Too large particle size or too high moisture content of the material entering the mill will increase the grinding burden.

Solutions:

• Pre-crushing: crush the material to ≤25mm before entering the mill to reduce the load of the ball mill.

• Control moisture: the moisture of the material is ≤5% during dry grinding, and it can be appropriately relaxed during wet grinding, but mud should be avoided.

• Energy-saving effect: optimizing the feeding conditions can reduce energy consumption by 8%-12%.

3. Use variable frequency speed regulation technology

Problem: The traditional ball mill runs at a fixed speed, which is easy to cause "idling" or overload, wasting electricity.

Solutions:

• Install a frequency converter to dynamically adjust the speed according to the load (usually 70%-80% of the critical speed).

• Combine with the PLC control system to achieve automatic adjustment.

• Energy-saving effect: variable frequency technology can reduce ineffective operation and save energy by 15%-20%.

4. Improve the liner structure

Problem: Traditional smooth liners have high friction and low efficiency of steel ball dropping, which affects the grinding effect.

Solution:

• Use corrugated, stepped or rubber liners to increase the height of steel ball dropping.

• Check the wear of the liner regularly to avoid increased friction resistance due to deformation.

• Energy-saving effect: Optimizing the liner can improve grinding efficiency and reduce energy consumption by 5%-10%.

5. Introduce intelligent control system

Problem: Manual operation is difficult to optimize the operation status of the ball mill in real time.

Solution:

• Install sensors (current, temperature, vibration monitoring) to adjust the feed rate and speed in real time.

• Use AI algorithm to predict the optimal operating parameters to avoid "over-grinding" or under-grinding.

• Energy-saving effect: Intelligent control can save 10%-15% of energy and extend the life of the equipment.

Through the five techniques of optimizing steel ball ratio, controlling material particle size, variable frequency speed regulation, improving linings, and intelligent control, the energy consumption of ball mills can be significantly reduced and production efficiency can be improved. Enterprises can choose appropriate energy-saving solutions according to their own working conditions to achieve long-term cost reduction and efficiency improvement!