Spiral Chutes Conveyor | Gravity Chutes

In mineral processing, the short-distance, low-cost transportation of materials is one of the key factors determining overall operational efficiency and economic benefits. As a mineral processing equipment manufacturer with 20 years of experience, we understand the critical importance of choosing the right conveying equipment. Today, we will delve into a classic, efficient, and energy-saving solution – the spiral chute conveyor, also known as a gravity chute.

| Key Words | Spiral Chutes Conveyor | Gravity Chutes |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. In-depth Analysis of the Core Equipment: What is a Spiral Chute?

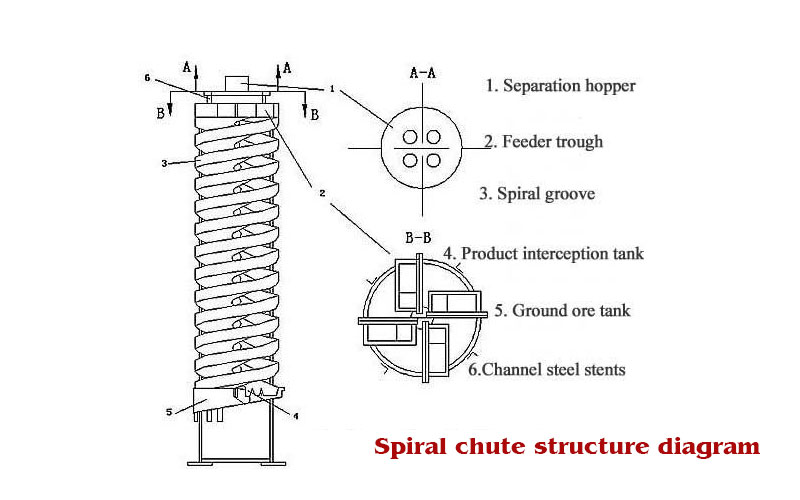

Spiral chute structure diagram

Working Principle of the Spiral Chute Conveyor

A spiral chute conveyor is essentially a device that utilizes gravitational potential energy for material transportation. It does not rely on any external power source (such as electric motors or diesel engines). Its core working principle is to allow materials to spiral downwards along a vertically or inclined installed spiral channel under the action of gravity, thus smoothly and continuously transporting them from a higher point to a lower point.

Equipment Structure and Overview

A standard spiral chute usually consists of the following parts:

• Feed inlet: Located at the top of the chute, used to receive incoming materials. It is usually designed with a buffer or guiding device to ensure uniform material entry into the chute.

• Spiral chute body: This is the core component of the equipment, made of steel plates rolled and welded together to form a continuous spiral surface. The inner wall is usually lined with wear-resistant materials (such as wear-resistant steel plates, ceramics, polyurethane, etc.) to greatly extend its service life.

• Central column/support structure: Provides stable support for the spiral chute body, ensuring its structural stability.

• Discharge outlet: Located at the bottom of the chute, materials are discharged from here after being transported by the spiral chute, and can be directly connected to the next process (such as a silo, belt conveyor, sorting equipment, etc.).

II. Why Choose a Gravity Chute? Detailed Explanation of its Core Advantages

Among numerous conveying equipment, the spiral chute conveyor is irreplaceable in specific scenarios due to its unique advantages:

1. Zero energy consumption operation, extremely low operating costs: Completely driven by gravity, requiring no electricity or fuel, saving significant energy costs in the long run, and conforming to the development concept of green mining.

2. Simple structure and convenient maintenance: The equipment has no moving parts, resulting in an extremely low failure rate. Daily maintenance work mainly focuses on checking the wear of the wear-resistant lining, significantly reducing maintenance costs and time.

3. Smooth operation and low noise: The material slides naturally in the chute, without mechanical impact or vibration, resulting in low noise pollution and a friendly working environment.

4. Flexible layout and space-saving: Vertical or large-angle arrangement effectively utilizes vertical space, especially suitable for factories with limited space or situations requiring material transport across multiple floors.

5. The conveying process combines deceleration and mixing: The spiral descent process naturally reduces the material flow rate, acting as a buffer; at the same time, the material rolls in the chute, providing a certain mixing effect.

III. Classic Application Case Sharing

In our 20 years of project experience, spiral chute conveyors have been successfully applied in numerous scenarios:

• Case 1: A certain iron ore processing plant: Between the crushing and screening workshops, a spiral chute was used to transport the lump ore discharged from the jaw crusher to the lower vibrating screen, replacing a short conveyor belt and saving energy consumption and maintenance costs.

• Case 2: A certain copper-molybdenum ore processing plant: In the grinding and classification circuit, a spiral chute lined with high-molecular wear-resistant material was used to smoothly transport the return sand from the spiral classifier to the ball mill feed port. The lining has not been replaced after five years of operation.

• Case 3: Coal washing plant: Used to transport raw coal or clean coal from high-level screening equipment to low-level storage bins or loading points, avoiding material breakage and maintaining the coal lump size.

IV. How to Choose and Related Equipment Recommendations

When choosing a spiral chute, key considerations include material characteristics (particle size, humidity, friction coefficient, abrasiveness), processing capacity, vertical drop, and on-site installation space. We can provide customized designs based on your specific working conditions, including chute diameter, pitch, and lining material.

Typically, spiral chutes are used in conjunction with the following equipment to form an efficient production line:

• Upstream equipment: Various crushers (jaw crushers, cone crushers), feeders.

• Downstream equipment: Vibrating screens, ball mills, jigs, shaking tables, or storage bins.

V. Frequently Asked Questions (FAQ)

Q1: Is a spiral chute suitable for conveying powdered materials?

A1: Caution is required during use. Very dry fine powders are prone to generating dust during the spiral descent. For powders or mixtures with a certain moisture content, this can be addressed by installing a dust cover on the trough or using water spray for dust suppression.

Q2: How does a spiral chute differ from a vertical bucket elevator?

A2: Although both are used for vertical conveying, their principles are quite different. Bucket elevators are mechanical lifting devices, consuming more energy and having higher investment and maintenance costs, but they offer greater lifting height and faster speed. Spiral chutes rely on gravity for downward movement, making them more economical and energy-efficient, but they require the material to have a sufficient angle of repose to ensure smooth sliding, and the conveying speed is slower.

Q3: How often does the wear-resistant lining typically need to be replaced?

A3: This depends on the abrasiveness of the conveyed material and the throughput. For example, when conveying highly abrasive materials such as iron ore, the wear-resistant steel plate lining may last 2-5 years; while for less abrasive materials such as coal, the service life can be 8 years or more. We will recommend the most economical lining solution based on the material analysis report.