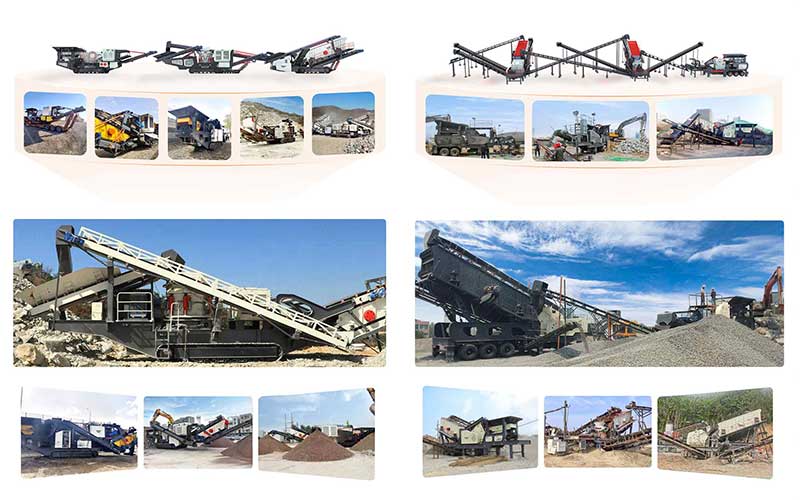

In industries like sand and gravel aggregate production, construction waste recycling, and mining, traditional fixed crushing lines are often limited by space, transportation, and installation costs. However, 100-150 TPH crawler mobile crushing stations are becoming the preferred choice for a growing number of companies due to their high production capacity, flexible relocation, and intelligent control.

This article will deeply analyze the core advantages, applicable scenarios, and technical features of 100-150 TPH crawler mobile crushing stations, and compare them with tire-type mobile crushing stations to help you make a more informed investment decision.

Core Advantages of the 100-150 TPH Crawler Mobile Crushing Station

1. Highly Efficient Production Capacity, Meeting Medium and Large-Scale Production Needs

• With a stable production capacity of 100-150 tons/hour, it is suitable for small and medium-sized sand and gravel plants and construction waste treatment projects.

• Utilizing a high-performance jaw crusher/cone crusher + vibrating screen combination, it is suitable for a variety of materials such as granite, basalt, and limestone.

2. Track Drive, Adaptable to Complex Terrains

• Compared to tire-type mobile crushers, the tracked chassis can operate stably in harsh environments such as muddy fields, hillsides, and mining areas, without the need for additional paved surfaces.

• The hydraulic drive system enables 360° on-the-spot steering, allowing for flexible positioning even in confined spaces.

3. Intelligent Control, Reduced Labor Costs

• The PLC intelligent control system provides one-button start/stop and fault alarms, reducing manual intervention.

• An optional remote monitoring system allows for real-time viewing of equipment operating status and production data.

4. Environmentally Friendly and Energy-Saving, In line with Green Production Trends

• Equipped with a pulse dust removal system to reduce dust pollution.

• The low-noise design meets the environmental requirements of urban construction waste recycling.

Application Scenarios: Which industries are most suitable for 100-150 TPH crawler mobile crushing plants?

1. Sand and Gravel Aggregate Production

• Suitable for small and medium-sized quarries, it can be crushed directly at the mine site, reducing transportation costs.

• Case study: A granite quarry in Fujian Province adopted this equipment, increasing production capacity by 30% and reducing overall costs by 20%.

2. Resource Utilization of Construction Waste

• Concrete, bricks, and other materials generated from urban demolition and old house renovation can be crushed on-site into recycled aggregate.

• Case study: A construction waste treatment project with an annual processing capacity of 500,000 tons and a recycling rate exceeding 90%.

3. Mining and Tailings Treatment

• Suitable for primary crushing in metal and coal mines, reducing ore transportation losses.

• Crushed tailings can be used for roadbed filling, achieving resource recycling.

Technical Analysis: Core Configurations of a 100-150 TPH Crawler Mobile Crushing Plant

| Components | Technical Parameters | Advantages |

| Crushing Main Unit | Jaw Crusher / Cone Crusher | High crushing ratio, suitable for hard rock |

| Feeder | Vibrating Feeder | Uniform feeding, avoiding blockages |

| Screening System | 3-Deck Vibrating Screen | Precise grading, improving product quality |

| Power System | Diesel Generator / External Power Supply | Adaptable to mining areas without electricity |

| Control System | PLC Intelligent Control | One-button operation, reducing manual labor |

Crawler vs. Tire-Type: How to Choose?

| Comparison Items | Crawler Mobile Crushing Plant | Tire Mobile Crushing Plant |

| Mobility | Crawler drive, adaptable to complex terrain | Requires truck towing, suitable for flat sites |

| Transfer Speed | Slow (0.5-1 km/h) | Fast (road-capable) |

| Applicable Applications | Mines, on-site construction waste processing | Sand and gravel plants, temporary projects |

| Price | Higher (but with higher long-term returns) | Lower (suitable for short-term projects) |

Conclusion:

• Long-term projects, complex terrain → Choose a crawler-type crusher (e.g., mining).

• Short-term projects, flat sites → Choose a wheel-type crusher (e.g., temporary sand and gravel production).

How to choose a cost-effective 100-150 TPH crawler-type mobile crusher?

1. Clarify your requirements: material hardness, required production capacity, and site conditions.

2. Compare brands: Focus on after-sales service, parts availability, and case studies.

3. Conduct on-site inspections: Request a trial run video or site visit from the manufacturer.

4. Customize: Choose a diesel-powered or electric-powered version based on your budget.

With stricter environmental protection policies and a shortage of sand and gravel resources, 100-150 TPH crawler-type mobile crushers, with their flexibility, efficiency, and environmental friendliness, will become core equipment for sand and gravel aggregate and construction waste processing.

If you are looking for a cost-effective mobile crushing solution, please contact us for a customized quote and technical solution!

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)