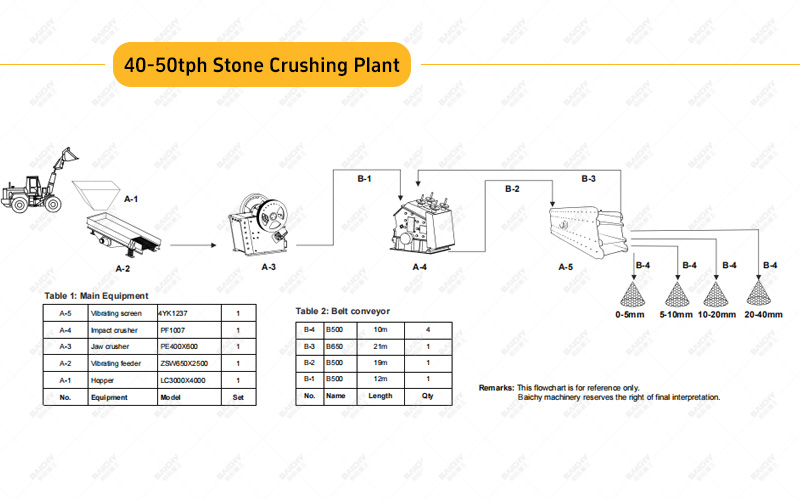

In South Africa's sand and gravel aggregate production sector, a 40-50 tons/hour (tph) crushing line is an ideal choice for small and medium-sized sand and gravel facilities. This line offers a moderate investment, a small footprint, and low operating costs, making it particularly well-suited for regional sand and gravel supply needs. This article will comprehensively analyze the key equipment selection considerations for a 40-50 tph crushing line, helping you build an efficient and cost-effective crushing system.

1. Core Equipment Selection for a 40-50 tph Crushing Line

1.1 Primary Crushing Equipment - Jaw Crusher

Recommended Models:

• PE400×600 (16-64 tph)

• PE500×750 (40-110 tph)

Technical Parameters:

• Feed Inlet Dimensions: 400×600mm or 500×750mm

• Maximum Feed Size: ≤340mm

• Discharge Adjustment Range: 40-100mm

• Motor Power: 30-55kW

• Equipment Weight: 6.5-12.5 tons

Selection Recommendations:

For a 40-50 tph production capacity, the PE500×750 is a more reliable choice, providing a more stable feed for subsequent processes. For budget constraints and more fragile materials, the PE400×600 is an option.

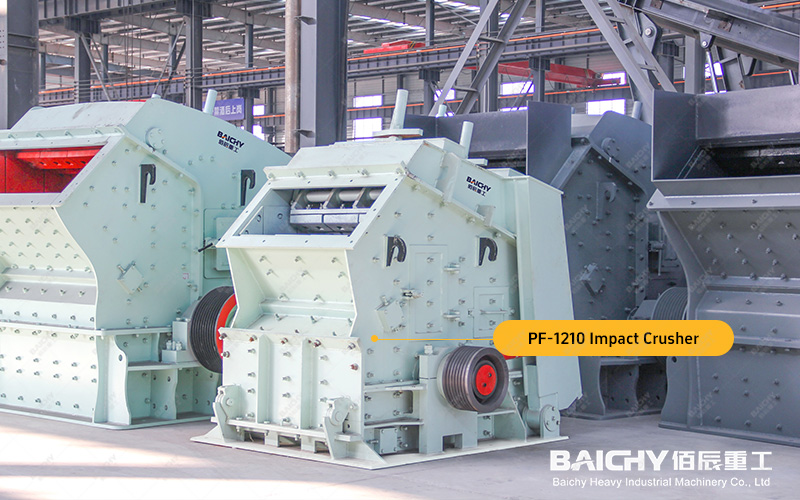

2.2 Secondary Crushing Equipment Selection

Depending on the material hardness, there are two main configuration options:

Option A: Medium-hard materials (limestone, dolomite, etc.)

Recommended equipment: Impact crusher

Recommended models:

• PF1010 (processing capacity 50-80 tph)

• PF1210 (processing capacity 70-130 tph)

Technical advantages:

• High crushing ratio (up to 20:1)

• Good particle shape, low flake content

• Easy maintenance, easy replacement of wearing parts

Option B: High-hardness materials (granite, basalt, etc.)

Recommended equipment: Cone crusher

Recommended models:

• PYB1200 (standard type, processing capacity 40-110 tph)

• PYD1200 (short head type, processing capacity 30-90 tph)

Technical advantages:

• Long wear-resistant parts life, low operating costs

• High crushing force, suitable for high-hardness materials

• Uniform product particle size

3. Screening Equipment Selection

Recommended models:

• 3YK1548 (three-deck screen, processing capacity 50-200 tph)

• 2YK1860 (two-deck screen, processing capacity 80-300 tph)

Configuration Key Points:

• Number of screen layers: 2-3 layers recommended

• Mesh size: Configure according to final product specifications (e.g., 0-5mm, 5-10mm, 10-20mm, etc.)

• Mounting angle: 15-20° is preferred

2. Auxiliary Equipment Configuration Plan

2.1 Feeding Equipment

• Vibrating Feeder: ZSW380×96

• Processing capacity: 80-150 tph

• Motor power: 7.5 kW

• Trough dimensions: 3800×960 mm

2.2 Conveying Equipment

• Belt conveyor: B650-B800

• Bandwidth: 650-800mm

• Belt Speed: 1.0-1.6m/s

Conveying Capacity: 100-200tph

2.3 Dust Removal System

• Pulse Bag Dust Collector:

• Air Volume: 6,000-10,000m³/h

• Filtration Area: 120-180㎡

• Dust Removal Efficiency: ≥99.5%

3. Production Line Layout Recommendations

Site Planning Key Points

• Equipment Spacing: Maintain 1.5-2m of maintenance clearance

• Conveyor Angle: ≤18° is recommended

• Stockpile Height: ≤5m to prevent material segregation

4. FAQs

Q1: What site size is required for a 40-50tph production line?

A: We recommend reserving a 30m x 40m (approximately 1,200㎡) site, including a raw material and finished product storage area.

Q2: How long does it take to build a production line?

A: From equipment procurement to commissioning, it typically takes 2-3 months.

Q3: How can I improve the actual output of my production line?

• Maintain uniform feed

• Regularly check the condition of the screen

• Promptly replace worn crushing chamber liners

• Optimize screening efficiency

Building a 40-50 tph crushing line requires comprehensive consideration of multiple factors, including material properties, product requirements, and investment budget. The equipment selection solutions provided in this article have been market-proven and can meet the production needs of most small and medium-sized sand and gravel facilities. Before making a final decision, we recommend consulting with a professional equipment supplier to conduct material testing and optimize the solution to ensure optimal operation of the production line.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)