1. Why choose 300-400TPH crawler mobile crushing station?

In mining, construction waste recycling, large-scale infrastructure and other projects, high-yield, flexible and low-energy consumption crushing equipment is the key to improving efficiency.

300-400 t/h (TPH) crawler mobile crushing station has become the industry's first choice with the following advantages:

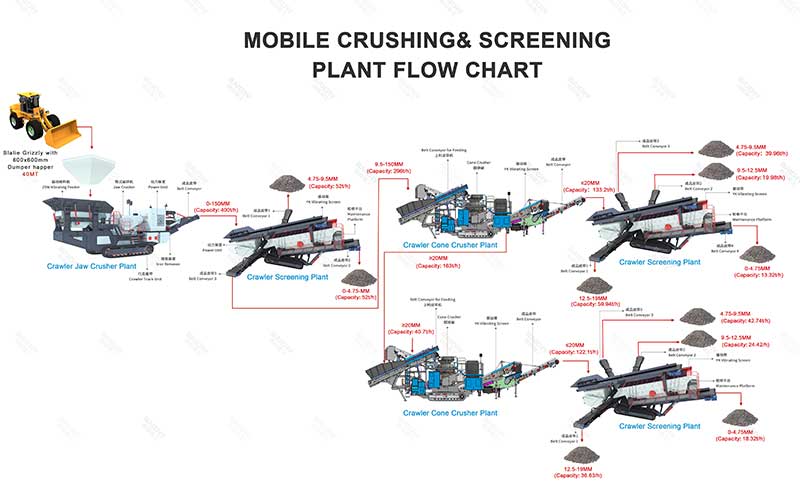

• High efficiency capacity: The processing capacity of a single machine reaches 300-400 t/h, meeting the continuous production needs of medium and large projects.

• Flexible transfer: The crawler drive does not require a trailer, adapts to complex terrain, and can be put into a new workstation within 1 hour.

• Multi-scenario adaptation: It can crush granite, basalt, concrete waste, etc., and supports "crushing-screening" integrated operations.

• Dual power selection: Diesel/electric dual mode, can still operate normally when there is no power supply.

Compared with similar equipment, our crushing station adopts an intelligent hydraulic adjustment system to optimize the crushing ratio in real time and reduce the risk of blockage by more than 30%.

2. Core configuration and technical parameters

• Recommended main models

| Model | Maximum feed size | Main crusher type | Discharge size range | Power configuration |

| CJ120 | 800mm | Jaw crusher | 50-200mm | Diesel + electric dual drive |

| HP300 | 650mm | Cone crusher | 20-100mm | Pure electric drive |

• Key performance highlights

✔ Low maintenance design: Hydraulic cover opening device facilitates maintenance and reduces downtime.

✔ Environmental protection and noise reduction: Closed structure + pulse dust removal, dust emission ≤ 20mg/m³.

✔ Intelligent monitoring: The remote control system provides real-time feedback on production, fuel consumption, and equipment status.

Click to download: Crawler Crusher Detailed Technical Manual

Large-scale crushing projects (such as 300-400TPH crawler mobile crushing stations) have a wide range of application scenarios, mainly targeting high-yield, high-intensity, and multi-site conversion operations. The following are typical application scenarios and specific case descriptions:

⑴ Mining and stone processing

Applicable materials: granite, basalt, limestone and other medium and high hardness ores.

• Project requirements:

▫ In the coarse or medium crushing stage of the mine, the raw ore is crushed into 50-200mm aggregates.

▫ Frequent adjustment of the working surface is required (such as open-pit layered mining).

• Advantages:

▫ Crawler mobility eliminates the infrastructure cost of fixed production lines and adapts to the complex terrain of the mining area.

▫ Diesel power solves the problem of no power supply in remote mining areas.

• Case:

▫ A large iron ore mine in Inner Mongolia uses a 300TPH crawler jaw crusher station, combined with a mobile screening machine, to realize an integrated production line of "mining-crushing-loading", with an average daily processing capacity of 5,000 tons.

⑵ Resource processing of construction waste

Applicable materials: concrete blocks, bricks and tiles, asphalt pavement waste, etc.

• Project requirements:

▫ On-site crushing at the demolition site to reduce transportation costs.

▫ Produce 0-40mm recycled aggregate for road cushion or brick making.

• Advantages:

▫ The closed design reduces dust pollution and meets environmental protection requirements.

▫ Hydraulically adjust the discharge particle size to meet different recycling purposes.

• Cases:

▫ In the urban old town renovation project, the mobile crushing station crushes the concrete waste into 0-30mm aggregates, ▫ which are directly used for the foundation of the new park, saving 60% of the raw material procurement cost.

⑶ Large-scale infrastructure projects (highways/railways/water conservancy)

Applicable materials: tunnel slag, roadbed excavation materials, river pebbles, etc.

• Project requirements:

▫ Multi-point operations along the project line, fast transfer.

▫ Crushed aggregates are used for roadbed filling or concrete mixing.

• Advantages:

▫ Modular design, station switching can be completed within 1 hour.

▫ The intelligent monitoring system provides real-time feedback on production to ensure project progress.

• Case:

▫ A section of the Sichuan-Tibet Railway uses a 400TPH mobile cone crusher to process tunnel blasting slag, with an average daily output of 6,000 tons of qualified aggregates, which are directly used for roadbed construction.

⑷ Large-scale production of sand and gravel aggregates

Applicable materials: natural rocks or tailings and waste rocks.

• Project requirements:

▫ High-yield continuous operation of centralized sand and gravel plants.

▫ Multi-stage crushing (jaw crusher + cone crusher + screening) linkage.

• Advantages:

▫ Diesel/electric dual mode reduces long-term energy consumption costs.

▫ Strong scalability (such as adding dust removal modules and fine crushers).

• Case:

▫ A large-scale gravel aggregate plant in South Africa is equipped with a dual unit of "crawler jaw crusher + crawler cone crusher", with an annual output of 2 million tons of high-quality machine-made sand, which is supplied to surrounding commercial mixing stations.

4. Key factors for scenario selection

| Scenario | Equipment selection focus | Supporting suggestions |

| Mine coarse crushing | Jaw crusher with large feed opening | With mobile screening station |

| Construction waste | Impact crusher (processing steel bar mixed materials) | Add magnetic separator to separate metals |

| Sand and gravel aggregate | Cone crusher (particle shape optimization) | Linked sand making module |

5. FAQ

Q1: What is the price range of 300-400TPH crawler mobile crushing station?

A: Depending on the configuration (such as whether it contains screening and dust removal modules), the price is usually 2-3.5 million yuan, and customized installment plans are supported.

Q2: Compared with fixed production lines, what are the advantages?

A: It saves infrastructure costs, especially suitable for short-term projects or multi-mine rotation operations, and the comprehensive investment return cycle is shortened by 50%.

Q3: Can this type of large equipment be used in narrow sites?

A: It can be adapted to confined spaces through folding conveyor design or split transfer, but the site needs to be planned in advance (the recommended minimum operating area is 30m×15m).

Q4: Is it suitable for crushing high-humidity materials (such as muddy ore)?

A: It is necessary to select a pre-screening + vibrating feeder to prevent sticking and blocking of the bin, or customize the heated feed port.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)