Limestone powder is an indispensable raw material in many fields such as building materials, metallurgy, and chemicals. For large-scale industrial production, selecting a grinding equipment with stable capacity, economical energy consumption, and easy maintenance is crucial.

Among them, a ball mill with a processing capacity of 10 tons per hour is an ideal choice to meet this requirement.

I. Why Choose a Ball Mill for Large-Scale Limestone Grinding?

As a classic grinding equipment, the ball mill demonstrates irreplaceable advantages when processing medium-hardness materials like limestone:

• High processing capacity and stable output: With a designed capacity of 10 tons/hour, the ball mill can optimize the cylinder length and diameter to ensure sufficient residence time for the material within the mill, achieving stable and continuous large-scale powder output.

• Reliable operation and strong adaptability: With a robust structure and mature design, it adapts well to changes in material moisture content and feed rate, ensuring continuous and stable operation of the production line and reducing unexpected downtime.

• Adjustable fineness and excellent particle morphology: By adjusting parameters such as the grinding media ratio and mill speed, the fineness of the output can be easily controlled, resulting in powder particles with uniform shape, good sphericity, and excellent quality.

• Simple operation and maintenance: The technology is mature, highly automated, and daily operation and maintenance are relatively simple, with controllable long-term operating costs.

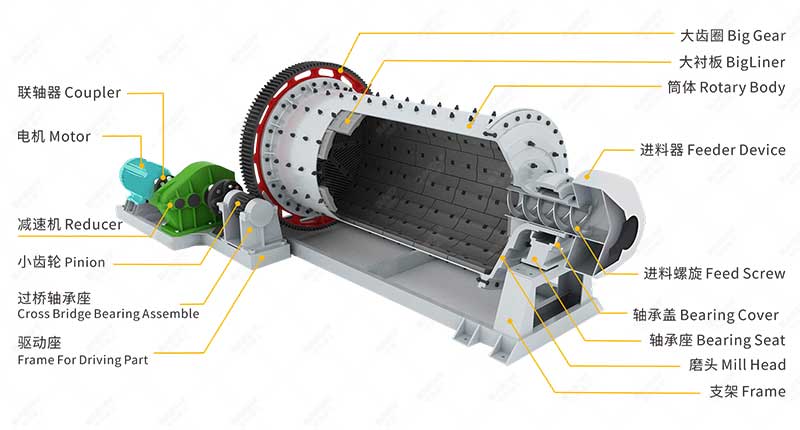

II. Core Working Principle of a 10-ton/hour Limestone

Ball Mill The grinding process of a ball mill is not complicated:

Crushed limestone material and steel balls (grinding media) of a certain size are fed into a uniformly rotating cylinder. As the cylinder rotates, the steel balls are carried to a certain height and then fall, generating a strong impact and grinding effect on the material inside the cylinder. Through collision and friction, the limestone particles are gradually ground into fine powder. The powder that meets the fineness requirements is discharged through the discharge device, becoming the final product.

III. Key Selection Factors for Achieving a 10 Ton/Hour Production Capacity

To achieve the expected production capacity, the following points should be considered during the selection process:

1. Mill Specifications: The diameter and length of the mill cylinder directly determine the grinding volume and production capacity. A 10-ton/hour output typically requires a medium to large-sized ball mill.

2. Grinding Media: The size, ratio, and filling rate of the steel balls directly affect grinding efficiency and finished product fineness. Scientific configuration based on the feed particle size and target fineness of the limestone is necessary.

3. Drive System: A powerful motor and reliable reduction gear are crucial for providing stable power, ensuring the mill operates efficiently at optimal speeds.

4. Supporting Equipment: The uniformity of the feeder and the sorting efficiency of the classifier are closely related to the final production capacity and require systematic consideration.

IV. Our Professional Solutions

Our 10-ton/hour limestone ball mill is designed and optimized based on extensive project experience. While ensuring rated capacity, it focuses on reducing energy consumption per unit product and minimizing wear parts consumption. We provide comprehensive technical support from equipment selection, installation, commissioning to after-sales maintenance to help you maximize your return on investment.

Choosing a suitable 10-ton/hour limestone ball mill is the cornerstone of building an efficient and profitable powder production line. If you are planning to upgrade or build a new production line, please feel free to contact us. Our technical experts will provide you with the most economical and reliable professional equipment solutions based on your specific operating conditions and needs.

Further reading:

How To Reduce The Energy Consumption Of Ball Mill? 5 Practical Energy-Saving Tips

How To Improve Ball Mill Efficiency? 5 Practical Tips

Ball Mill Maintenance Guide : 10 Key Methods To Extend Life

How To Choose A Suitable Ball Mill Model?