Ball mills are key equipment in industries such as mining, building materials, and chemicals, and their efficiency directly affects production capacity and operating costs. However, many users have found that ball mills are inefficient during use, resulting in high energy consumption and low output. So, how to optimize ball mill performance and improve grinding efficiency? This article will share 5 practical tips to help you improve ball mill efficiency, reduce energy consumption, and increase output!

1. Optimize the charging ratio to avoid overloading or underloading

The charging amount of the ball mill directly affects the grinding efficiency. Excessive charging will limit the movement of the grinding media (steel balls, ceramic balls, etc.), reduce the impact and grinding effect; Too little charging will reduce the collision between the media, which also affects the efficiency.

Recommendations:

• The charging amount should be controlled at 30%-40% of the ball mill volume (wet grinding can be appropriately increased).

• Regularly check the material filling rate to ensure that the grinding media is in full contact with the material.

2. Adjust the speed to find the best working speed

The speed of the ball mill determines the movement mode of the grinding media (slipping, throwing or centrifugal). If the speed is too low, the media cannot effectively impact the material; if the speed is too high, the media may be centrifugal and lose the grinding effect.

Recommendations:

• The optimal speed of the ball mill is usually 65%-75% of the critical speed (critical speed calculation formula: Nc = 42.3/√D, D is the inner diameter of the cylinder).

• Adjust the speed according to the hardness of the material. The speed can be appropriately increased for hard materials.

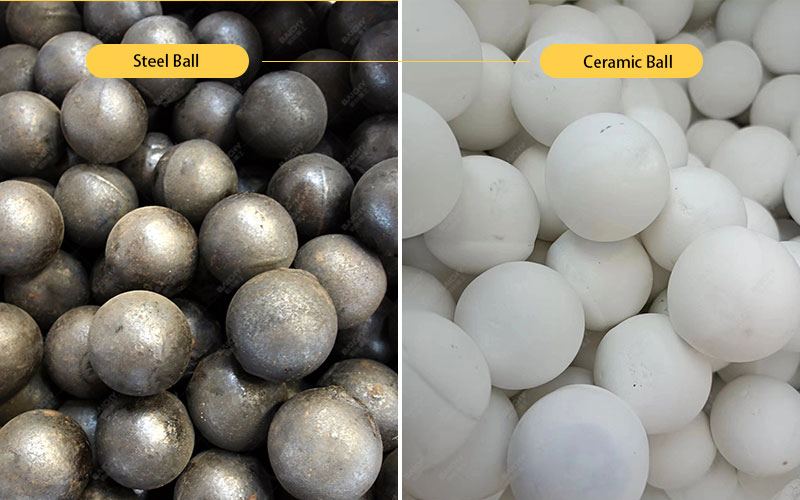

3. Choose suitable grinding media (steel balls, ceramic balls, etc.)

The material, size and ratio of the grinding media directly affect the grinding effect. Too large or too small media will reduce efficiency, and media of different materials are suitable for different materials.

Recommendations:

• Steel balls: suitable for hard materials (such as iron ore and gold ore).

• Ceramic balls: suitable for non-metallic ores (such as quartz and kaolin) to reduce iron pollution.

• Media ratio: Use multi-level ratio (such as mixing large, medium and small balls) to improve grinding uniformity.

4. Control the feed particle size to avoid excessively large particles affecting grinding.

If the feed particle size is too large, the ball mill will take longer to grind, resulting in increased energy consumption and decreased efficiency.

Recommendations:

• Add crushing equipment (such as jaw crusher, cone crusher) in front of the ball mill to control the feed particle size to ≤25mm.

• Regularly check the screening system to prevent substandard materials from entering the ball mill.

5. Regular maintenance to reduce equipment wear

Long-term wear of the liner, bearings, gears and other parts of the ball mill will lead to reduced efficiency and even malfunction and shutdown.

Recommendations:

• Regularly check the liner wear and replace it in time (general life 6-12 months).

• Lubrication system maintenance to ensure that the bearings and gears are well lubricated and reduce friction loss.

• Monitor motor current. Abnormal fluctuations may indicate equipment problems.

The key to improving ball mill efficiency is to optimize charging, adjust speed, select suitable media, control feed size and perform regular maintenance. With these 5 tips, you can significantly improve grinding efficiency, reduce energy consumption and increase production!

Further reading: