PE500x750 Jaw Crusher Manufacturer

In the mining industry, efficiency and cost are always core issues. Facing increasingly stringent environmental requirements, rising operating costs, and the demand for higher output, the upgrading and transformation of mining equipment has become an inevitable trend in the industry's development. As a mining crushing equipment manufacturer with 20 years of experience, we deeply understand our customers' pain points and firmly believe that choosing a reliable jaw crusher is the first step to successful mine transformation. The PE500x750 model is undoubtedly a long-standing star product in this process, a key force in helping mines achieve a new lease of life.

| Key Words | PE500x750 Jaw Crusher Manufacturer |

|---|---|

| Product Model | Jaw Crusher |

| Feed Size | ≤425mm |

| Motor Power | 45kw |

| Capacity | 40-130t/h |

| Core Advantages | Deep cavity design |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why is the PE500x750 the ideal choice for upgrading and transformation?

Mine upgrading and transformation is not simply about replacing old equipment with new; it's about maximizing efficiency, minimizing energy consumption, and ensuring the most stable operation within existing site constraints, budget, and process chain. Many older mines use crushing equipment that may suffer from insufficient capacity, high energy consumption, frequent breakdowns, and poor product particle shape. The PE500x750 jaw crusher, as a medium-sized primary crushing equipment, precisely matches these transformation needs in terms of processing capacity, feed size, and structural reliability, achieving the most significant efficiency improvements with minimal modifications.

Equipment Overview: A Robust and Durable Crushing Core

The PE500x750 is a classic double-toggle jaw crusher, its model name directly revealing its core parameters: a feed opening size of 500mm x 750mm. This means it can easily handle various ores and rocks with a particle size of no more than 425mm, making it the undisputed first choice for primary crushing in the production line. Its structure uses high-quality steel and mature manufacturing processes, ensuring stable operation even in heavy-duty, harsh mining environments.

Core Advantages: Why can it help with upgrading?

1. Excellent Reliability and Durability: As a manufacturer with 20 years of experience, we strive for excellence in the design and material selection of key components such as the movable jaw, eccentric shaft, and bearing housing. The manganese steel jaw plates have strong wear resistance, significantly reducing maintenance costs and downtime, providing a solid foundation for continuous production.

2. Significant Increase in Production and Efficiency: With a processing capacity of 40-110 tons/hour, it effectively overcomes the capacity bottleneck of existing crushing lines. The optimized crushing chamber design delivers a higher crushing ratio, resulting in better primary crushing and reducing the pressure on subsequent equipment.

3. Excellent Energy Consumption Control: Compared to older equipment, the PE500x750 uses a more efficient transmission system and optimized motion parameters, resulting in lower energy consumption at the same output, directly reducing long-term operating costs for customers and aligning with the concept of green mining development.

4. Strong Material Adaptability: Whether it's hard rocks like granite and basalt, or medium-hard materials like limestone and shale, it can handle them with ease, providing equipment assurance for persified mining of mineral resources.

5. Convenient Retrofitting and Installation: Its compact structure and mature foundation design allow for better adaptation to existing site layouts in retrofitting projects, shortening the installation and commissioning cycle and enabling mines to resume production faster.

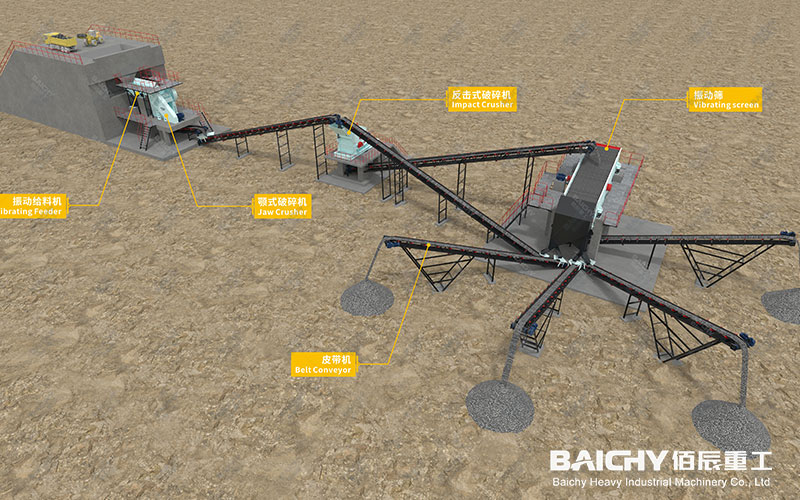

Jaw Crushing Plant

Application Case: A Leap from Theory to Practice

We provided an upgrade solution for a limestone mine in Central China. The mine originally used an old jaw crusher with low capacity, high dust emissions, and excessive power consumption. We replaced it with a PE500x750 jaw crusher and optimized the front-end feeding system. After the upgrade:

• Increased Capacity: Hourly output increased from 50 tons to 85 tons.

• Reduced Costs: Unit power consumption decreased by approximately 18%.

• Environmental Compliance: With a sealed design, dust concentration at the work point was significantly reduced.

The customer reported that the equipment runs smoothly, is easy to maintain, and the return on investment far exceeded expectations.

Related Equipment Recommendations: Building an Efficient Crushing Production Line

An excellent primary crushing equipment requires powerful "teammates." We recommend considering the following equipment in retrofitting projects to create a synergistic effect:

• Secondary and Tertiary Crushing Equipment: Impact crushers or cone crushers, used for fine crushing of the coarse material produced by the PE500x750.

• Screening Equipment: Circular vibrating screen, to achieve material classification, forming a closed-loop system to improve overall efficiency and finished product quality. • Feeding and Conveying System: Vibrating feeder and belt conveyor ensure smooth material flow and guarantee continuous and stable operation of the entire line.

Frequently Asked Questions (FAQ)

Q: What is the maximum feed size of the PE500x750?

A: The maximum feed size is approximately 425mm, which is the ideal feed size for primary crushing equipment.

Q: What is the motor power of the equipment? What about energy consumption?

A: The main motor power is typically 55kW. Due to its high efficiency, it is an energy-saving equipment among similar products. The specific energy consumption needs to be comprehensively evaluated based on the hardness of the material.

Q: What is the replacement cycle for wear parts such as jaw plates?

A: This mainly depends on the abrasiveness of the crushed material. For medium-hard limestone, the jaw plate life can reach 6-12 months or even longer. We provide high-quality original jaw plates to ensure optimal service life.

Q: As a manufacturer with 20 years of experience, what support can you provide?

A: We provide one-stop service from site survey, solution design, equipment installation and commissioning to operation training and spare parts supply. Our technical team is a strong support for your upgrade and renovation projects.

Q: Is the equipment suitable for mobile crushing plants?

A: Absolutely. The PE500x750 is a classic core component for building wheeled or tracked mobile jaw crushing plants, especially suitable for mining or engineering projects that require relocation.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.