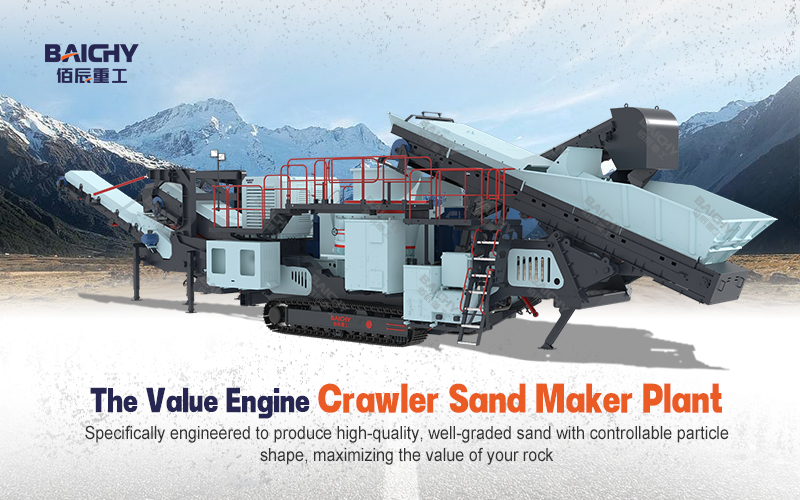

In mining operations, construction waste recycling, and large-scale engineering construction sites, tracked mobile crushing plants, with their high mobility, rapid relocation, and integrated operation capabilities, have become synonymous with modern, efficient crushing solutions. As a professional manufacturer of mobile mining crushing equipment, we understand that the core of a successful mobile crushing production line lies in the scientific and rational selection of core equipment tailored to different material properties, capacity requirements, and product specifications.

This manual will delve into the eight mainstream models to help you build the most suitable mobile crushing system.

Coarse Crushing Stage: A Pioneer in High-Efficiency Breakthrough – Tracked Jaw Crusher

The first hurdle in a mobile production line determines the efficiency and stability of subsequent processes. Coarse crushing equipment must possess strong impact resistance and high throughput.

CJ Series European Jaw Crusher: The Top Choice for Hard Rock Coarse Crushing

Our tracked jaw crusher station is equipped with the CJ series European jaw crusher, which offers significant advantages in hard rock crushing:

Superior Crushing Efficiency and Capacity: Adopting a weld-free, modular frame design for higher strength; the optimized deep "V" shaped crushing chamber and larger stroke result in a higher crushing ratio and processing capacity.

Exceptional Durability: The moving jaw assembly uses an integral cast steel bearing housing, integrated with the frame, providing a load-bearing capacity far exceeding that of a split design. The jaw plates are made of high-strength manganese steel for a longer service life.

Intelligent Adjustment and Protection: Hydraulic adjustment of the discharge port allows for simple and precise operation; the overload protection device quickly releases foreign objects, preventing equipment damage and ensuring continuous and stable operation.

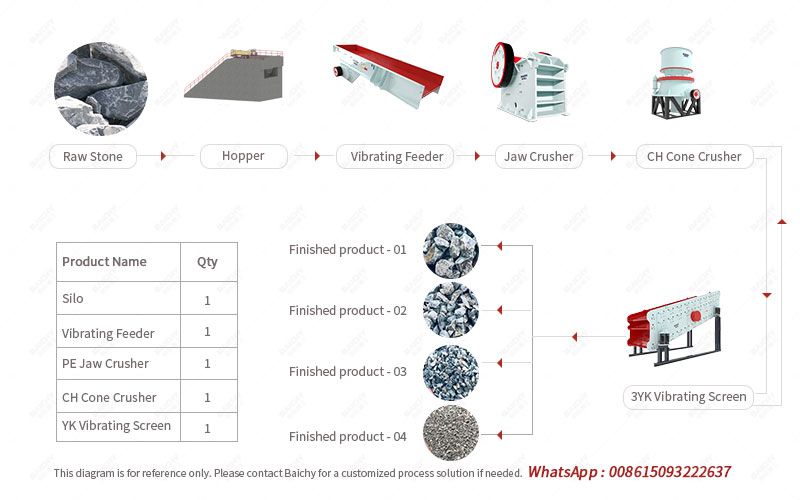

Medium and Fine Crushing Stage: The Key to Precise Shaping

After coarse crushing, the material enters the medium and fine crushing stage, which is crucial for controlling the final product particle size. Based on the material hardness and particle shape requirements, there are two main technical paths.

Tracked Cone Crusher: The "Expert" in Fine Crushing of Hard Rock

For highly abrasive hard rocks such as granite, basalt, and river pebbles, the tracked cone crusher is the first choice to ensure both production capacity and the economic efficiency of wear-resistant parts. The key to selection lies in the hydraulic system.

Single-cylinder hydraulic cone crusher: Compact structure, high degree of automation, and easy maintenance. Suitable for medium-capacity hard rock crushing scenarios focused on stable production.

Multi-cylinder hydraulic cone crusher: Provides higher crushing force and finer lamination crushing, resulting in better product particle shape and controllable fine powder content. Ideal for large-scale hard rock crushing projects pursuing high production capacity and high-quality aggregates.

Tracked Impact Crusher: The "Versatile" in Medium Crushing of Soft Rock

For medium-to-low hardness materials such as limestone, coal gangue, and construction waste concrete, the tracked impact crusher is an efficient and economical choice for medium crushing.

"Top Choice for Medium Crushing of Soft Rock": Utilizing impact energy to crush materials, it achieves excellent "stone-on-stone" and "stone-on-iron" effects, producing cubic particles with low needle-like and flaky content, making it ideal as concrete aggregate.

Flexible and Adjustable: By adjusting the rotor speed and impact plate gap, the product particle size can be easily changed, making it a multi-purpose machine.

Sand Making and Shaping Stage: The Core of Value Enhancement – Tracked Impact Crusher Station

High-quality manufactured sand is key to increasing product added value. Tracked impact crushers (usually equipped with VSI6X vertical shaft impact crushers) are the perfect tool for this task.

VSI6X Vertical Shaft Impact Crusher Sand Particle Shape Control: Employing a combination of "stone-on-stone" and "stone-on-iron" principles, its optimized four-impeller deep cavity design significantly improves throughput and sand yield. Its core particle shape control technology effectively shapes the sand, producing high-quality manufactured sand with reasonable gradation and sharp edges, greatly meeting the demand for high-grade concrete sand.

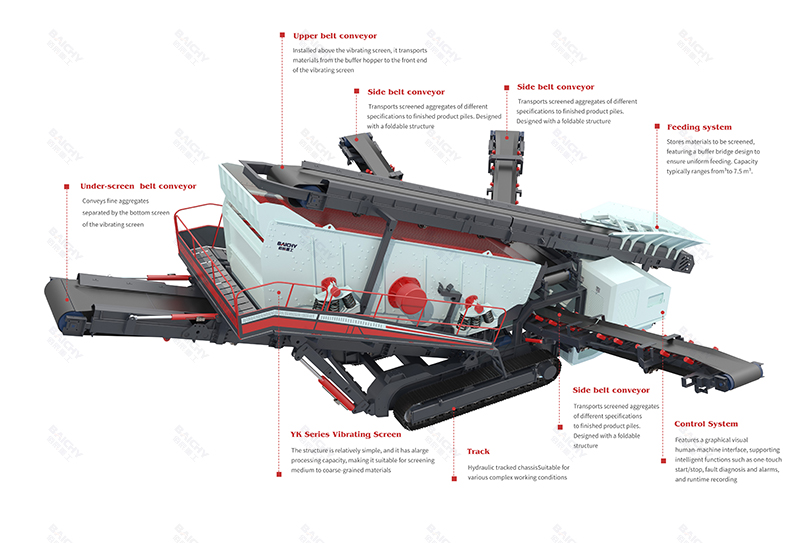

Screening Stage: The Central Hub of Fine Grading – Tracked Screening Station

Screening is the "quality inspector" connecting each crushing stage and ensuring the final product specifications. Mobile screening stations are mainly divided into inclined and horizontal types.

Tracked Inclined Screening Station: Compact structure, suitable for sites with limited space, high screening efficiency, and is the standard configuration for most mobile crushing lines.

Tracked Horizontal Screening Station: Provides a larger screening area and smoother material flow, particularly suitable for screening wet, sticky materials or scenarios requiring multi-layer fine grading.

Screen Configuration and Capacity Matching: Selecting the appropriate number of screen layers, aperture, and material (such as polyurethane, rubber, manganese steel) is a decisive factor in matching the front-end crushing capacity and ensuring grading accuracy. It needs to be comprehensively considered based on material characteristics, humidity, and target product specifications.

Power Solution Comparison: Choosing the Right "Heart"

The power source of a mobile station directly affects operating costs, environmental requirements, and site adaptability.

Diesel Drive: Applicable Boundaries: Remote mines without fixed power sources, new construction sites, or projects requiring frequent relocation. The advantages are strong independence and flexible deployment.

Pure electric drive: Applicable scenarios include fixed or semi-fixed processing plants with stable industrial power supplies (such as construction waste treatment centers) and urban operations with extremely high environmental and noise requirements. Advantages include low energy costs, zero on-site emissions, and low noise.

Hybrid electric drive: Applicable scenarios that combine flexibility and economy. Diesel power is used during relocation, and the system switches to electric motor drive after relocation, combining the advantages of the former two and representing one of the future mainstream trends.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!