In the mining and large-scale building materials production sectors, a crushing capacity of 250 tons per hour (TPH) represents a strategically significant benchmark. It perfectly matches the long-term, stable material requirements of most medium-sized stone quarries, commercial concrete mixing plants, and large-scale infrastructure construction projects. Choosing a 250 TPH stationary crushing line means finding the optimal balance between investment costs, operational efficiency, and market demand.

As a manufacturer of mobile crushing equipment, we deeply understand the core logic of stationary production lines. The advantages of stationary crushing plants lie in their robustness, efficiency, and durability, making them suitable for sites with stable raw materials and production cycles lasting several years or even decades. The 250 TPH configuration is the key starting point for achieving economies of scale and reducing per-ton costs.

| Key Words |

stationary crushing equipment |

| Product Model |

Stone Crushing Plant |

| Capacity |

0-2000t/h |

| Core Advantages |

Multi-stage fragmentation and reshaping |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Overview of the 250 TPH Stationary Crushing Line: Core Components and Workflow

A complete 250 TPH stationary stone crushing production line is not a single piece of equipment, but a collaborative "system." Its core objective is to process large blocks of raw stone (such as granite, basalt, limestone, etc.) through multi-stage crushing and screening to produce high-quality construction aggregates of various specifications that meet national standards.

Standard Process Flow Analysis

Primary Crushing Stage: A jaw crusher is typically used as the "pioneer," responsible for the first stage of crushing large raw stones ≤750mm, producing primary crushed material ≤200mm.

Secondary and Tertiary Crushing Stage: This is the key stage for achieving the target capacity. Cone crushers or impact crushers are the main equipment, further crushing the primary crushed material in preparation for screening. For a 250 TPH stationary crushing plant, one or more large-cavity, high-performance secondary crushing machines are usually configured.

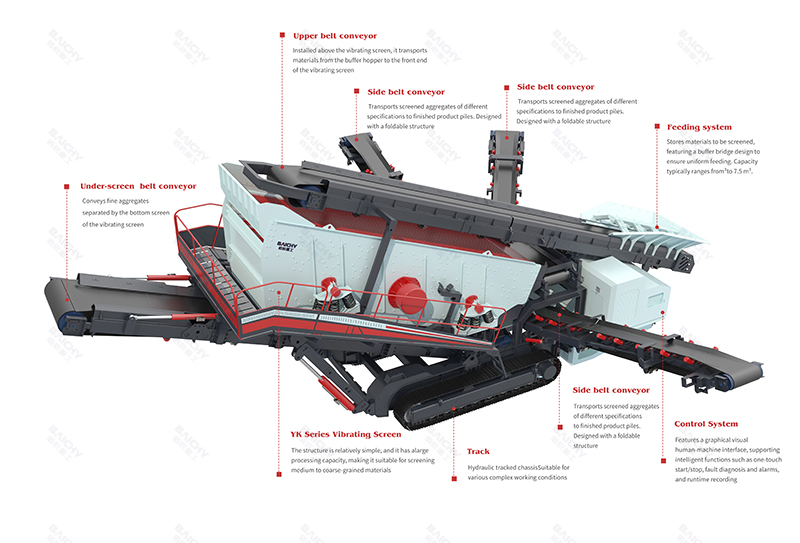

Screening and Recycling Stage: Vibrating screens classify the crushed mixture by particle size (e.g., 0-5mm, 5-10mm, 10-20mm, 20-31.5mm). Qualified finished products are transported to the finished product stockpile by conveyor belts, while oversized particles are returned to the secondary or tertiary crusher for reprocessing through a recycling system, forming a closed-loop cycle to ensure particle shape and capacity.

Symons Cone Crusher

Impact Crusher

Core Advantages of Investing in Stationary Crushing Plants

Unlike the flexible mobility of mobile crushing plants, stationary production lines offer irreplaceable advantages in specific application scenarios:

Extremely high production stability and reliability: The equipment has a solid foundation and compact connections, capable of withstanding long-term, high-load continuous operation with a low failure rate, ensuring the achievement of annual production targets.

Lower operating cost per ton: Significant economies of scale mean that electricity consumption and wear part costs are more economical when spread across each ton of finished product. Optimized equipment layout and shorter material transfer paths result in lower energy consumption.

Excellent finished product quality control: Utilizing a mature closed-circuit design and multi-stage screening, it can precisely control product particle size distribution and shape, meeting the high standards required for commercial concrete aggregates.

High degree of automation and intelligence: Easy integration of centralized electrical control systems, online monitoring, and automated feeding adjustment reduces reliance on manual labor, improving safety and management efficiency.

Classic Case Study: A Granite Aggregate Project

Project Overview: A granite aggregate production line in Central China with an annual output of 2 million tons, supplying raw materials to surrounding highways and commercial concrete plants.

Core Requirements: Stable output of high-quality, multi-specification aggregates at over 250 TPH, reliable equipment operation, and easy maintenance.

Solution: We planned and provided the core crushing equipment and a complete process design solution. The production line uses a three-stage closed-circuit process of "jaw crusher (primary crushing) + single-cylinder hydraulic cone crusher (secondary crushing) + multi-cylinder hydraulic cone crusher (tertiary crushing)," combined with a three-layer heavy-duty vibrating screen.

Operating Results: The production line achieved a stable output of 270-280 TPH, with excellent finished product particle shape and low flakiness content, fully meeting the national standard for Class I aggregates. The equipment ran smoothly, earning long-term recognition from the customer.

Related Equipment Recommendations and Synergy

As a manufacturer of mobile crushing equipment, we understand the pain points of starting and maintaining stationary production lines.

We recommend:

Track-mounted mobile jaw crusher: Used for initial mine development, overburden stripping, or as an emergency backup primary crushing unit for stationary production lines, providing "mobile flexibility" to complement "stationary stability."

Mobile Screening Plant: Can temporarily "fill in" during maintenance of fixed lines, or be used for processing surplus raw materials from fixed lines, recycling construction waste, and other auxiliary operations, maximizing asset utilization.

Frequently Asked Questions (FAQ) about 250 TPH Fixed Crushing Plants

1. How much investment is required for a 250 TPH fixed crushing line?

The price is a result of multiple factors, not just the price of a single piece of equipment. The total investment typically ranges from several million to tens of millions of RMB, with the main differences being:

Equipment brand and configuration: There is a significant price difference between imported high-end brands and domestic first-tier or second-tier brands.

Automation level of the production line: Electrical control systems, dust removal, noise reduction, and other environmental protection standards.

Non-equipment costs: Civil engineering, steel structures, installation, power facilities, etc. It is recommended to conduct detailed material testing and overall scheme design before obtaining an accurate quotation.

2. Fixed or mobile, which should I choose?

This depends on your project cycle and material characteristics.

Choose fixed: If your material source is fixed, the mining period is long (>3 years), you have extremely high requirements for capacity and finished product quality, and the power supply is stable.

Choose mobile: If your work sites are scattered, the project cycle is short, frequent relocation is required, and there is an urgent need for rapid commissioning. As a professional manufacturer, we can provide you with the most neutral selection advice.

3. What are the key factors affecting the stable production capacity of a 250 TPH plant?

In addition to the equipment performance itself, the following points are crucial:

Raw material hardness and humidity: Overly hard or sticky materials will reduce throughput.

Continuity and uniformity of feeding: Avoiding "starvation" or "overfeeding" is the lifeline of stable operation.

Scientific process design and equipment matching: The crushing ratio distribution at each stage, screening efficiency, and return material balance must be precisely calculated.

Pre-screening and soil removal: Removing soil and fine materials before coarse crushing can greatly improve the efficiency of the main crushing line.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!